Oxygen-absorbing resin composition

一种树脂组合物、树脂层的技术,应用在合成树脂层状产品、挠性覆盖物、包装物品类型等方向,能够解决强度降低、包装容器强度降低等问题,达到高成形加工性和透明性、保存性优异、高吸氧性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

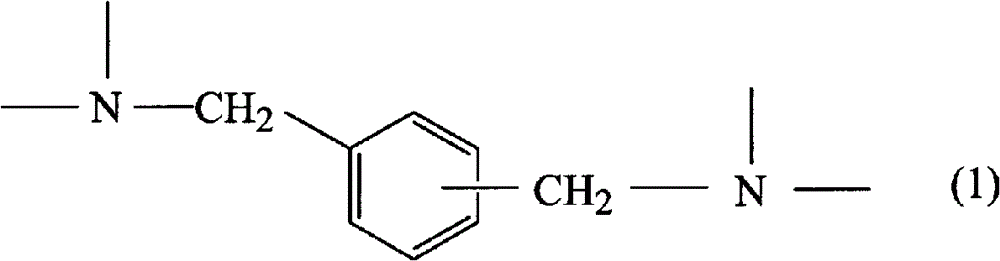

Method used

Image

Examples

Embodiment 1A

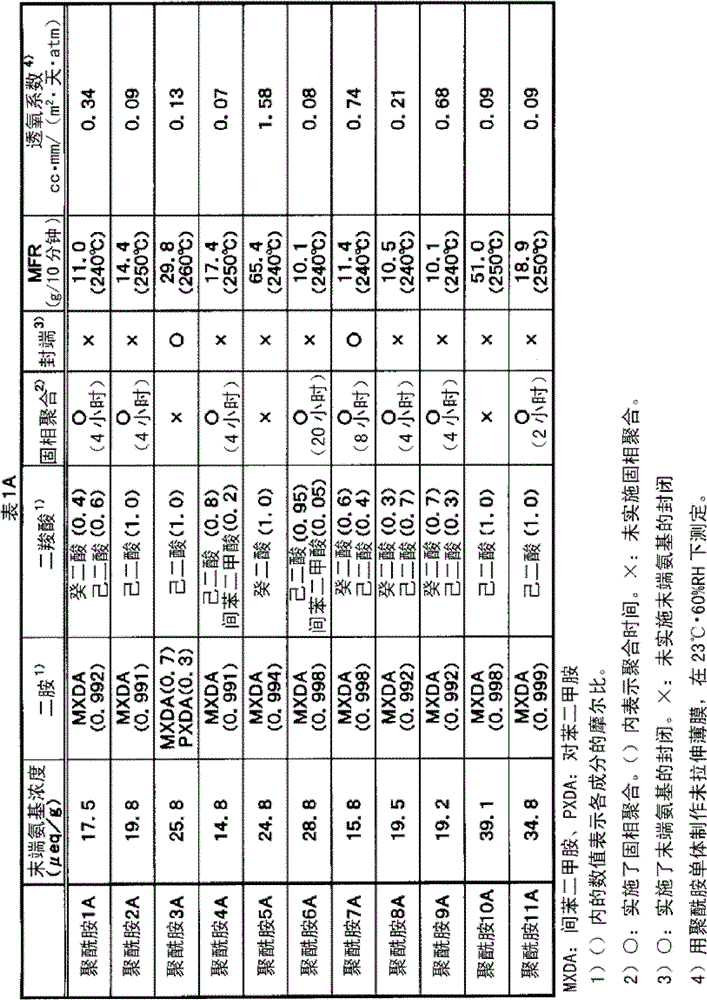

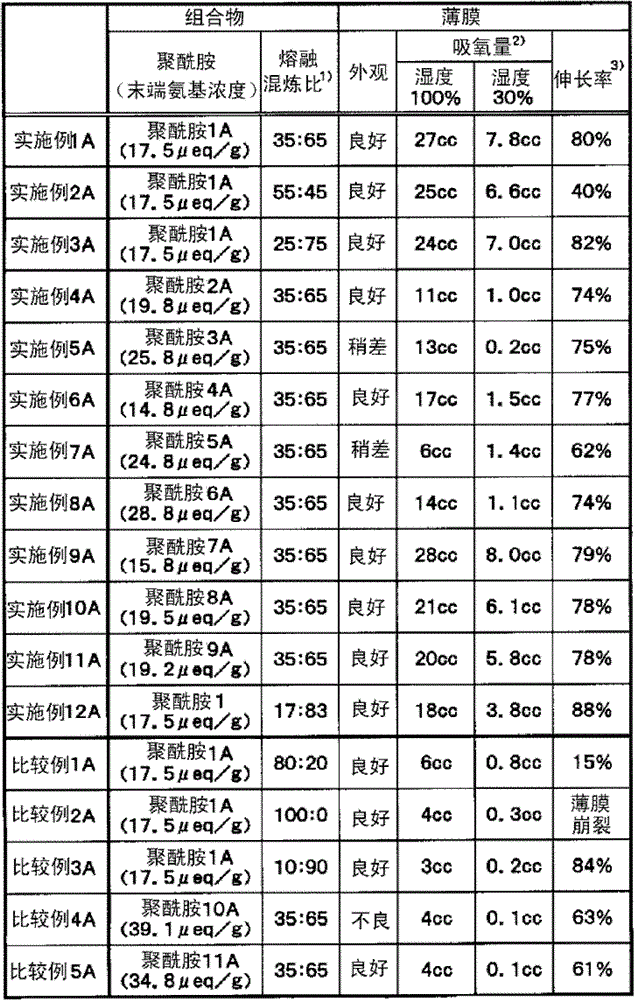

[0200] Using m-xylylenediamine: sebacic acid: adipic acid at a molar ratio of 0.992:0.4:0.6, a polyamide resin was synthesized by melt polymerization and solid state polymerization under the aforementioned synthesis conditions (hereinafter, the polyamide The resin is described as polyamide 1A). In addition, the dropping time was set to 2 hours, the reaction time of melt polymerization was set to 1 hour, the pressure in the device during solid phase polymerization was set to 1 torr or less, the polymerization temperature was set to 160° C., and the polymerization time was set to 4 hours. Hour. Polyamide 1A has a Tg of 73°C, a melting point of 184°C, a half-crystallization time of over 2000 seconds, a terminal amino group concentration of 17.5 μeq / g, a terminal carboxyl group concentration of 91.6 μeq / g, a number average molecular weight of 23,500, and an MFR of 240°C It was 11.0 g / 10 minutes. In addition, the obtained polyamide 1A monomer was used to make an unstretched film,...

Embodiment 2A

[0203] A film was produced in the same manner as in Example 1A except that the weight ratio at the time of melt kneading was set to cobalt stearate-containing polyamide 1A:LLDPE=55:45, and the film was subjected to measurement of oxygen absorption and elongation. Rate measurement and appearance observation. Their results are shown in Table 2A.

Embodiment 3A

[0205] A film was produced in the same manner as in Example 1A except that the weight ratio during melt kneading was set to cobalt stearate-containing polyamide 1A:LLDPE = 25:75, and the film was subjected to measurement of oxygen absorption, elongation Rate measurement and appearance observation. Their results are shown in Table 2A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com