Low gloss polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, applied in the field of polypropylene compositions, can solve the problems that have not yet been given a good solution, the mechanical properties of the product or the decline of the matting performance, and achieve good matting performance, easy operation, good resistance The effect of impact properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of matting modifier:

[0025] (1) Matting modifier A

[0026] Fully vulcanized powdered nitrile rubber (VP-401, average particle size 0.1 μm, gel content 90wt%; Sinopec Beijing Research Institute of Chemical Industry) and grafted polypropylene (g-PP, American EXXON company, brand 4401, maleic anhydride Grafting rate 2.5%) in a weight ratio of 1:0.5, mixed uniformly to prepare matting modifier A. Its specific formulation is shown in Table 1.

[0027] (2) Matting modifier B

[0028] Fully vulcanized powdered nitrile rubber (same as above) and grafted polypropylene (same as above) are mixed uniformly at a weight ratio of 1:0.3 to prepare matting modifier B.

[0029] (3) Matting modifier C

[0030] Fully vulcanized powdered nitrile rubber (same as above), grafted polypropylene (same as above) and silicon dioxide (U.S. Grace Company, brand C807, particle diameter 7 μm, pH value 3.3, porosity 2ml / g) in a weight ratio of 1 : 0.5: 0.5, mixed uniformly to prepar...

Embodiment 1

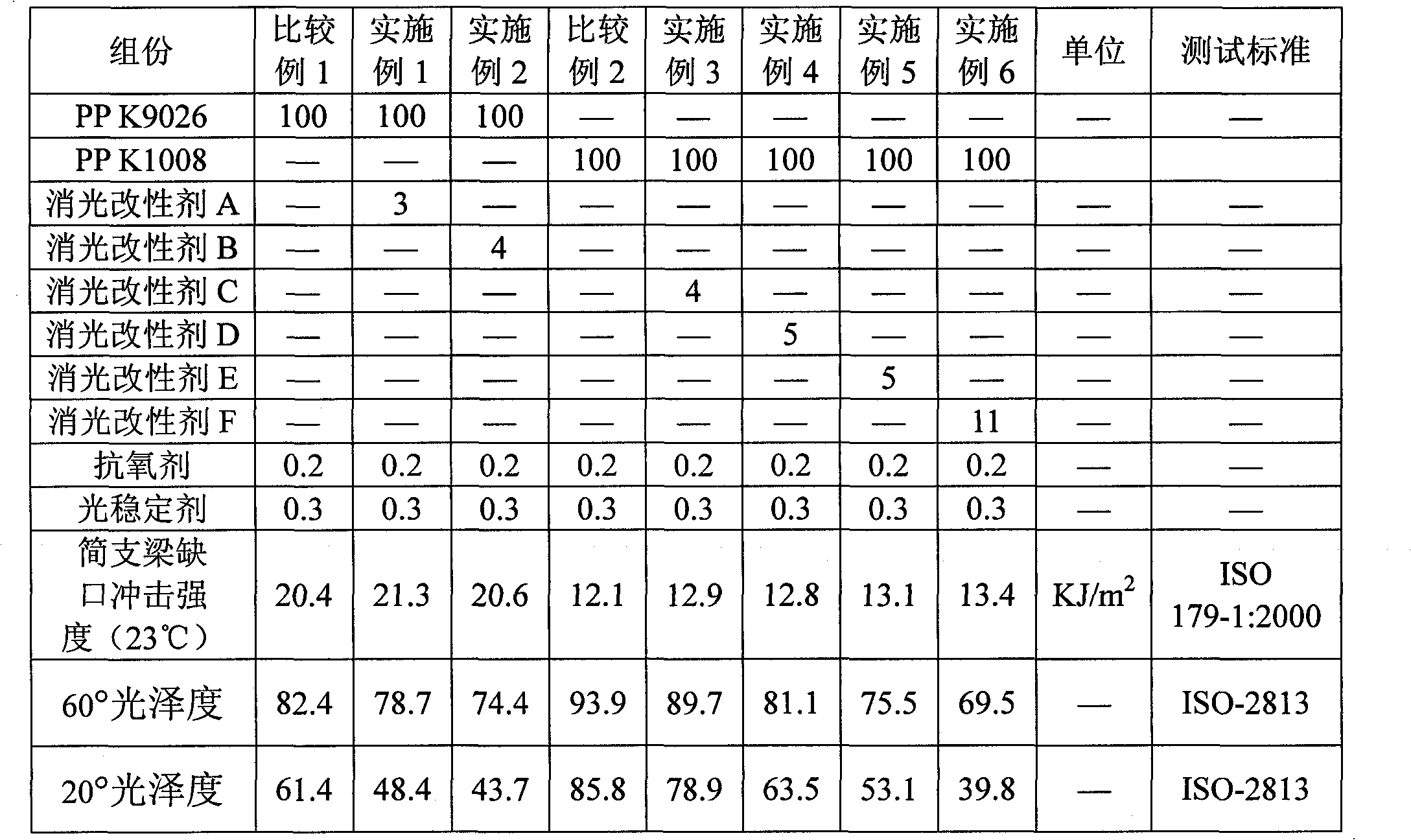

[0038] Polypropylene K9026 (melt index 26g / 10min, Sinopec Beijing Yanshan Petrochemical Company), matting modifier A, antioxidant (Irganox 1010 and Irgafos 168 in a weight ratio of 1:1 compounded, Ciba, Switzerland Fine Chemical Company), light stabilizer (Swiss Ciba Fine Chemical Company, brand Tinuvin326) after stirring evenly, use twin-screw to extrude and granulate under the condition of 190-230 ℃, and its specific formula is shown in Table 2.

[0039] The prepared composition is injected into a sample with an injection machine, and the impact resistance, extinction and other performance tests are carried out. Among them, the impact resistance test is tested according to the international standard test method ISO 179. Gloss test using JFL-BZ20 ° 60 ° 85 ° intelligent gloss meter, the test conditions are: (1) stability: 0.4 gloss unit (Gs) / 30 minutes; (2) measurement window size: 16 × 48 (mm ); (3) The surface of the test piece is a mirror finish.

[0040] The test resu...

Embodiment 2

[0042] The matting modifier B was used to replace the matting modifier A, and the remaining components, preparation and testing process were the same as in Example 1, and the specific formula and test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com