Preparation method of large-dimension multi-element rare earth boride (Ce0.9Pr0.1)B6 single crystal

A rare earth boride, single crystal technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of high current density, unavailable, poor substrate adhesion, etc., and achieve large growth size and good symmetry , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

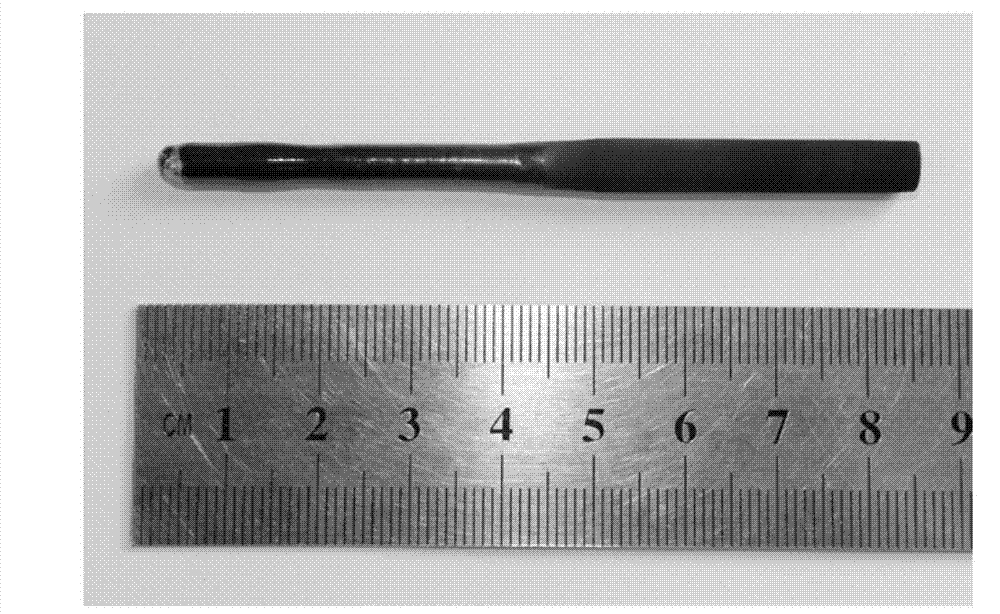

[0018] 1) the CeB 6 Powder, PrB 6 The powder was ball milled and mixed according to the atomic ratio of 9:1, and then loaded into a graphite mold. Place the mold in the SPS sintering cavity, evacuate until the total pressure reaches 5 Pa, raise the temperature to 1150 °C at a heating rate of 100 °C / min, keep it for 5 min, and cool to room temperature with the furnace to obtain (Ce 0.9 PR 0.1 )B 6 polycrystalline rod;

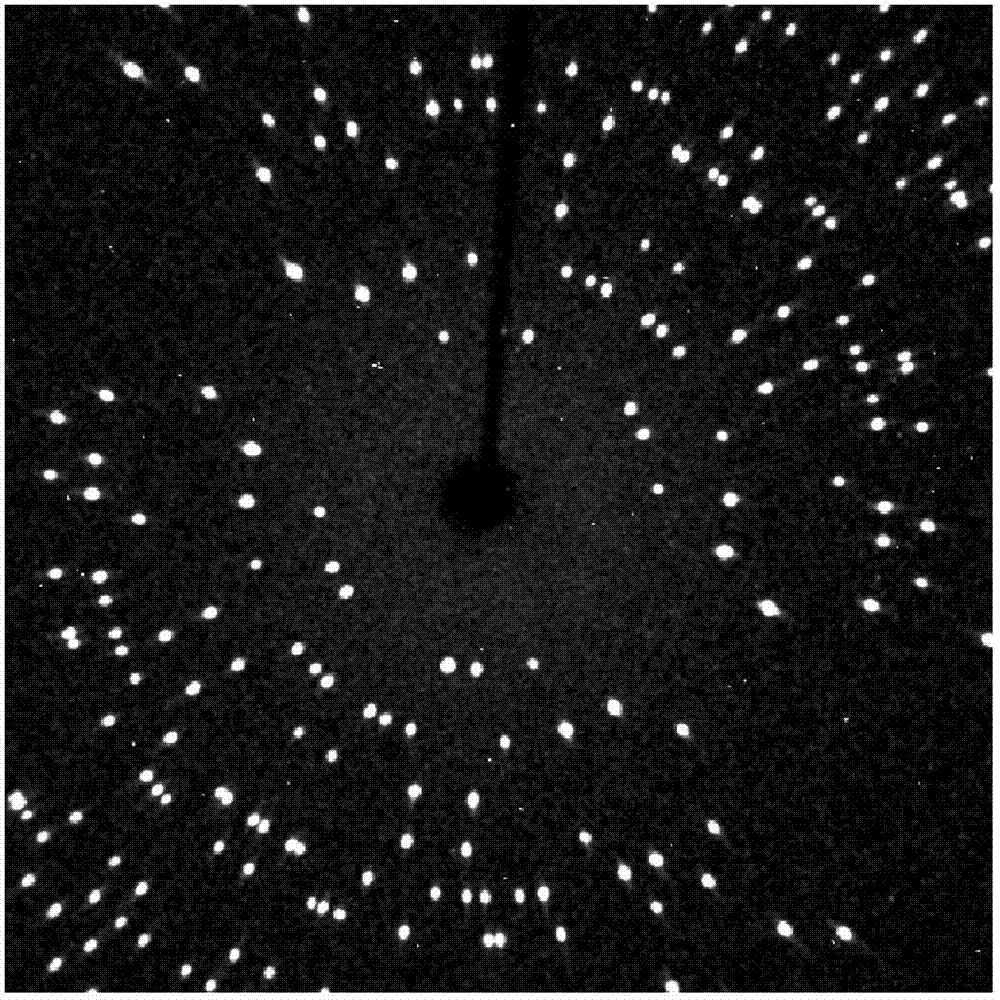

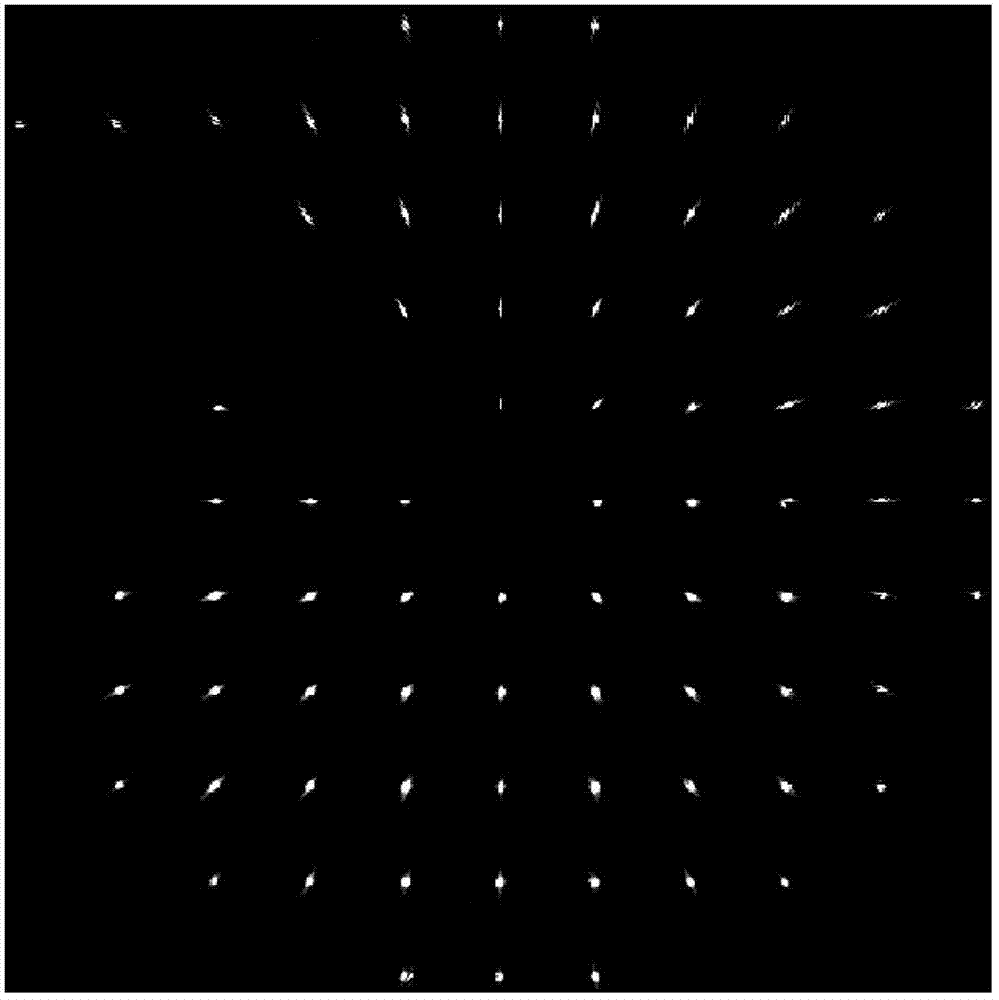

[0019] 2) Using an optical zone melting furnace, with a diameter of 8mm (Ce 0.9 PR 0.1 )B 6 The polycrystalline rod is the first zone melting for seed crystal and material rod. After the equipment is evacuated to below 1Pa, flow argon gas into it until the pressure rises to 0.5MPa, the gas flow rate is 2L / min, and the power of the furnace in the 30min zone is increased until both the seed crystal and the material rod are melted and a stable melting zone is formed. During the crystal growth process The rotation speed is 30rpm, and the unit of crystal grow...

Embodiment 2

[0022] 1) the CeB 6 Powder, PrB 6 The powder was ball milled and mixed according to the atomic ratio of 9:1, and then loaded into a graphite mold. Place the mold in the SPS sintering cavity, evacuate until the total air pressure reaches 5Pa, raise the temperature to 1100°C at a heating rate of 80°C / min, keep the temperature for 3min, and cool to room temperature with the furnace to obtain (Ce 0.9 PR 0.1 )B 6 polycrystalline rod;

[0023] 2) Using an optical zone melting furnace, with a diameter of 6mm (Ce 0.9 PR 0.1 )B 6 The polycrystalline rod is the first zone melting for seed crystal and material rod. After the equipment is evacuated to below 1Pa, flow argon gas into it until the pressure rises to 0.5MPa, the gas flow rate is 1.5L / min, and the power of the furnace in the 30min zone is increased until both the seed crystal and the material rod are melted and a stable melting zone is formed, and the crystal growth process The medium speed is 30rpm, and the unit of cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com