Driving system of hybrid electric vehicle based on continuously variable transmission

A technology of hybrid electric vehicles and continuously variable transmission, which is applied in the direction of hybrid electric vehicles, motor vehicles, power plants, etc., can solve the problems of small starting torque, complicated structure, and complex structure of pure electric vehicles, and achieve high operating reliability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

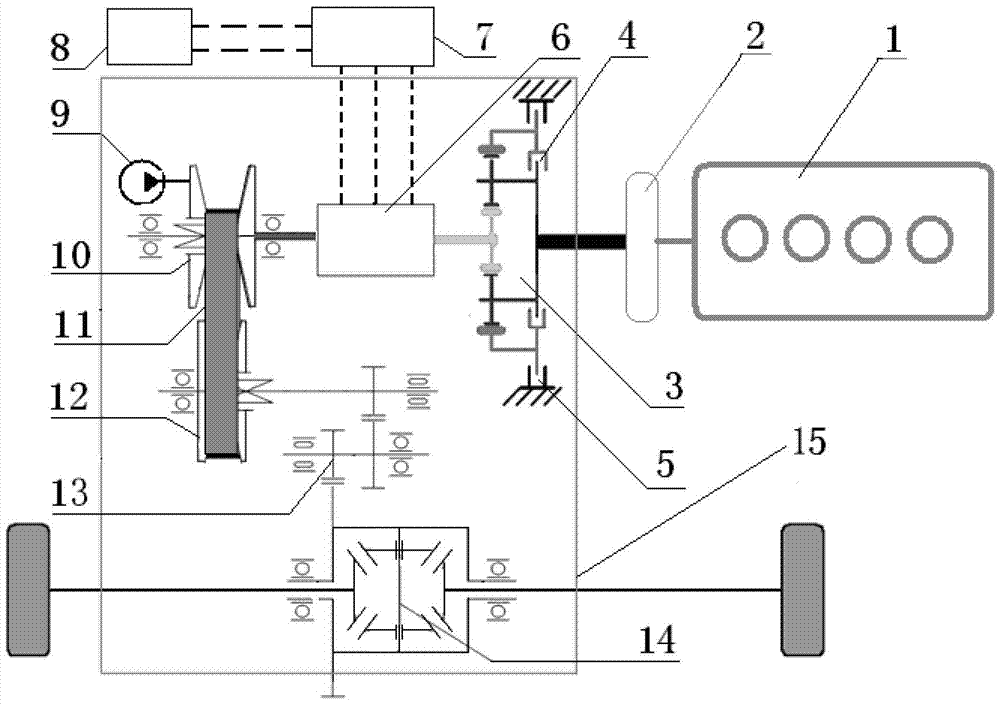

[0027] Refer to attached figure 1 As shown, a hybrid electric vehicle drive system based on continuously variable transmission described in the present invention includes an internal combustion engine 1, a dual-mass flywheel 2, a planetary gear mechanism 3, a forward clutch 4, a reverse brake 5, a drive motor 6, and a motor Controller 7, battery 8, electric oil pump 9, driving pulley 10, metal belt 11, driven pulley 12, reduction mechanism 13, differential gear assembly 14. Wherein the components except the internal combustion engine 1, the dual-mass flywheel 2, the motor controller 7 and the battery 8 are integrated together to form a continuously variable transmission 15 for hybrid power.

[0028] The internal combustion engine 1 is connected to the planetary carrier of the planetary gear mechanism 3 in the special hybrid continuously variable transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com