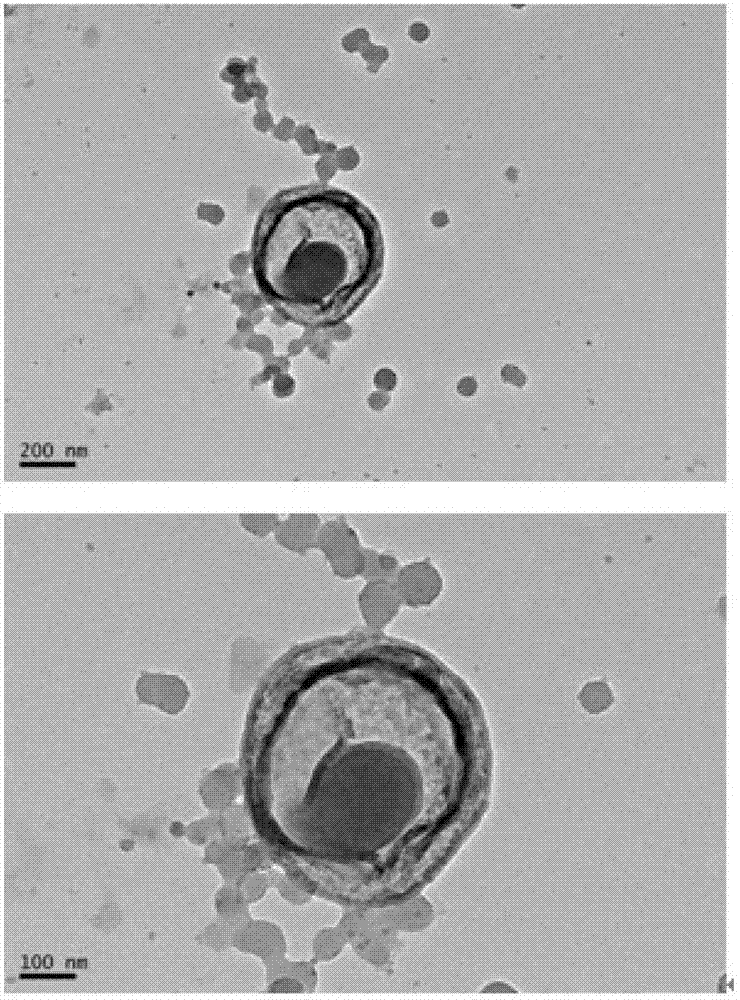

Silica/poly(methyl methacrylate-styrene) double-layered composite microsphere and its preparation method

A technology of methyl methacrylate and silicon dioxide, which is applied in the field of silicon dioxide/poly double-shell composite microspheres and its preparation, can solve the problem of poor release effect of capsule-encapsulated drugs, ineffective effect, and preparation process cumbersome and other problems, to achieve the effect of release and treatment, easy molecular weight and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of waterborne polyurethane includes the following raw materials:

[0039] Isophorone diisocyanate IPDI 8.88 parts

[0040] Polypropylene glycol PPG 20 parts

[0041] Dimethylol propionic acid DMPA 1.34 parts

[0042] Hydroxyethyl methacrylate HEMA 2.86 parts

[0043] Triethylamine TEA 1.01 parts

[0044] The specific preparation method is as follows:

[0045] Weigh IPDI and PPG (relative molecular mass: 1000), blow in nitrogen, remove the air in the system, react at 85°C for 3 hours; add DMPA, react at 85°C for 3 hours; cool down to 70°C, add HEMA for capping reaction 3 hours; cool down to 50°C, add TEA to the system for neutralization, stir rapidly and add water to disperse to obtain waterborne polyurethane.

[0046] Preparation of silica / poly(methyl methacrylate-styrene) double-shell composite microspheres comprises the following raw materials:

[0047] Methyl methacrylate MMA 14 parts

[0048] γ-Methacryloxypropyltrimethoxysilane MPS 1.2 parts ...

Embodiment 2

[0059] The raw material and concrete preparation method of preparing waterborne polyurethane are as follows:

[0060] (with embodiment 1)

[0061] The preparation of silicon dioxide / P(MMA-St) double-shell structure composite microspheres comprises the following raw materials:

[0062] Methyl methacrylate MMA 14 parts

[0063] γ-Methacryloxypropyltrimethoxysilane MPS 1.2 parts

[0064] Orthoethyl silicate TEOS 6 parts

[0065] Hexadecane HD 0.8 parts

[0066] Azobisisobutyronitrile AIBN 0.2 parts

[0067] Waterborne polyurethane WPU 1.76 parts

[0068] Styrene St 7 parts

[0069] 80 parts of water

[0070] Concentration of 28% NH 3 ·H 2 O 1.5 parts

[0071] The specific preparation method is as follows:

[0072] (with embodiment 1)

Embodiment 3

[0074] The raw material and concrete preparation method of preparing waterborne polyurethane are as follows:

[0075] (with embodiment 1)

[0076] The preparation of silicon dioxide / P(MMA-St) double-shell structure composite microspheres comprises the following raw materials:

[0077] Methyl methacrylate MMA 12 parts

[0078] γ-Methacryloxypropyltrimethoxysilane MPS 1.2 parts

[0079] Orthoethyl silicate TEOS 6 parts

[0080] Hexadecane HD 0.8 parts

[0081] Azobisisobutyronitrile AIBN 0.2 parts

[0082] Water-based polyurethane WPU 0.88 parts

[0083] Styrene St 12 parts

[0084] 80 parts of water

[0085] Concentration of 28% NH 3 ·H 2 O 1.5 parts

[0086] The specific preparation method is as follows:

[0087] (with embodiment 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com