Method for decreasing carbon deposits on carbon residue removing catalyst of residual oil hydrotreater

A technology of residual oil hydrogenation and treatment device, which is applied in the direction of hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc. The effect of saving cold hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

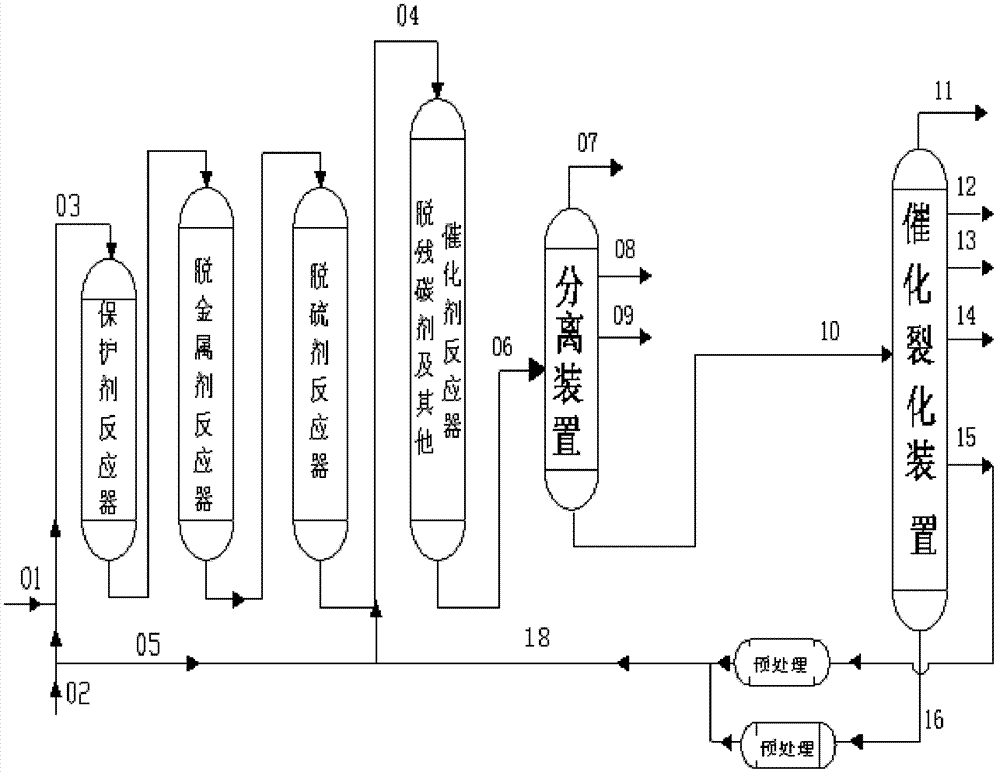

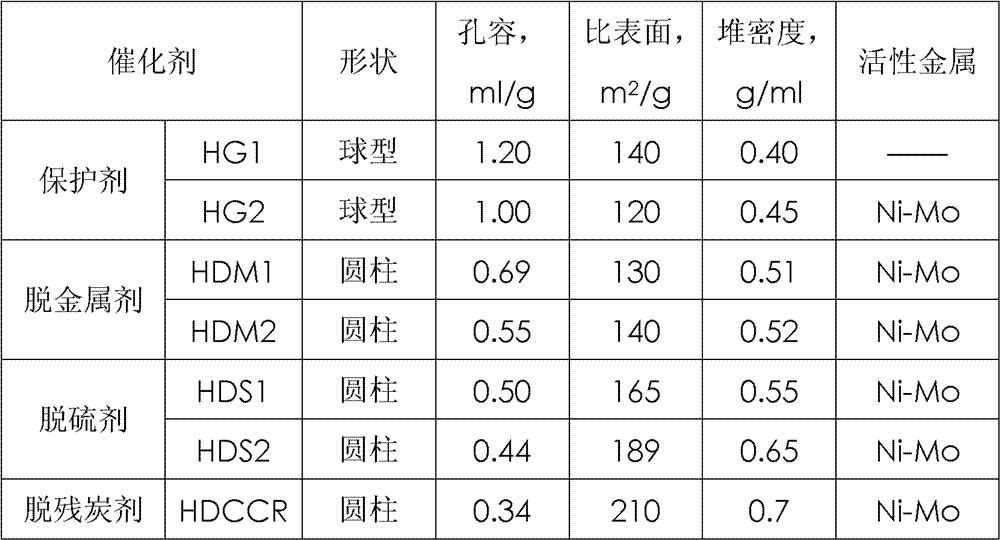

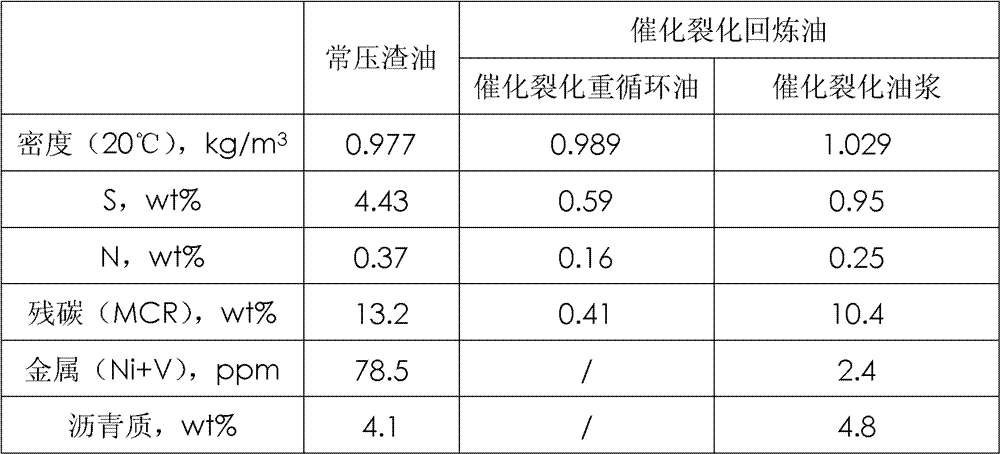

Method used

Image

Examples

Embodiment 1

[0041] The residual oil and hydrogen mixed oil directly enter the residual oil hydrogenation pilot plant, and the catalytic cracking and refining are the same as in the comparative example. After mixing with supplementary hydrogen, it enters the residual oil hydrogenation reactor through the front feed port of the carbon removal agent bed, and the same The reaction was carried out according to the conditions in Table 3, and the reaction products were separated into gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated residue.

[0042] From Table 6, we can know that, compared with Comparative Example 1, the carbon deposit of the carbon residue removal agent in Example 1 is 9.5% lower, and the estimated operating period of the catalyst is 1 month longer than that of Comparative Example.

[0043] Table 44000 hours residue hydrogenation product data and catalyst carbon deposition

[0044]

Embodiment 2

[0048] The residual oil and hydrogen mixed oil directly enter the residual oil hydrogenation pilot plant, and the catalytic cracking back to the refining oil is the same as that of the comparative example, and enters the residual oil hydrogenation reactor through the front feed port of the carbon removal agent bed, also according to the conditions in Table 3 The reaction is carried out, and the reaction product is separated into gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated residue.

[0049] From Table 6, we can know that, compared with Comparative Example 2, the carbon deposit of the carbon residue removal agent in Example 2 is 5.2% lower, and the estimated operating period of the catalyst is 1 month longer than that of Comparative Example.

[0050] Table 54,000 hours residue hydrogenation product data and catalyst carbon deposition

[0051]

Embodiment 3

[0055] Residual oil and hydrogen mixed oil directly enter the residual oil hydrogenation pilot plant, catalytic cracking and refining are the same as in the comparative example, enter the residual oil hydrogenation reactor through the front feed port of the desulfurizer bed, and react according to the conditions in Table 3 , The reaction product is separated into gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated residue.

[0056] Through Table 6, we can know that, compared with Comparative Example 3, the carbon deposit of the carbon residue removal agent in Example 3 is 6.5% lower, and the expected operating period of the catalyst is 1.5 months longer than that of Comparative Example.

[0057] Table 64000 hours residue hydrogenation product data and catalyst carbon deposition

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com