Mineral oil-containing waste comprehensive utilization system and method

A mineral oil and waste technology, applied in the field of municipal sludge treatment, can solve the problems of poor quality of recovered oil, low oil recovery rate, poor treatment effect, etc., to improve the quality of recovered oil, reduce the speed of coking, and reduce coking volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

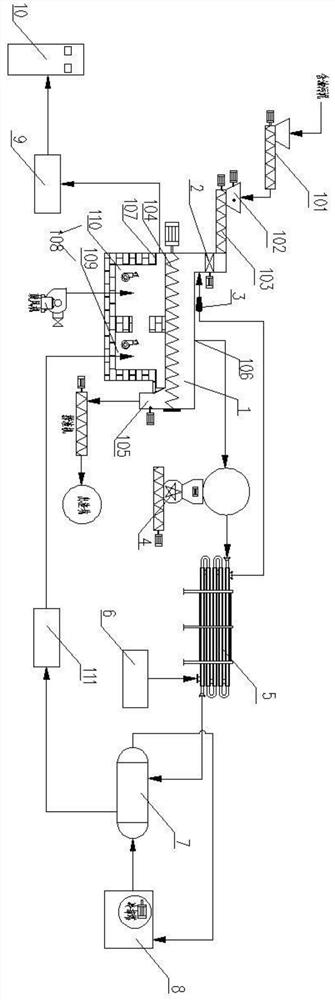

[0043] Such as figure 1 As shown, a comprehensive utilization system of mineral oil-containing wastes includes a feed section and a main reaction device 1, a crushing assembly 2 and an airflow impact assembly 3 are arranged between the main reactor and the feed section, and the airflow impact assembly 3 It is perpendicular to the falling direction of the material, and the oily sludge enters the main reaction device 1 after being crushed by the feeding part through the crushing component 2 and the airflow impact component 3;

[0044] The rear side of the main reaction device 1 is provided with a flue gas dust collection device 4 and an economizer 5, one end of the economizer 5 is connected to the air flow impact assembly 3, one end of the flue gas dust collection device 4 is connected to the main reactor, and the other end is connected to the main reactor. One end is connected to the economizer 5, and the flue gas from the main reaction device 1 passes through the flue gas dust...

Embodiment 2

[0060] The present embodiment provides a method for comprehensive utilization of mineral oil-containing waste, which comprises the following steps:

[0061] Step 1: Determine the agent, and determine the type and volume ratio of the inhibitor by testing the oily sludge raw material; the type and volume ratio of the inhibitor are 10-20% 1,2-dichloroethane (EDC) + 30-50% dimethyl sulfide + 40%-60% tris (trimethylsilyl) phosphite mixture,

[0062] Inhibitors can improve the quality of recovered oil and prevent coking and scaling. The explanation for the anti-coking effect is as follows: the organic sulfur in the inhibitor can decompose HS free radicals under anaerobic high-temperature cracking conditions, making the reaction zone As the concentration of free radicals increases, the free radicals can react with the metal surface to passivate the metal surface, inhibit the coking process on the surface of the reactor, and reduce the amount of coking; while the phosphide in the inhi...

Embodiment 3

[0072] This embodiment is based on the system of embodiment 1 and the method of embodiment 2, taking oil-based cuttings processing capacity of 5t / h, oil content of 25%, water content of 40%, and solid content of 35% as an example:

[0073] (1) Add 18% 1,2-dichloroethane (EDC) + 34% dimethyl sulfide + 48% tris(trimethylsilyl) phosphite mixture to the pretreated oily sludge , the addition ratio is 350ppm, and stir evenly;

[0074] (2) The argon gas heated up to 200°C by heat exchange from the economizer 5, after being compressed, is accelerated into a supersonic airflow through the Laval nozzle, injected into the pulverization port, and meets the oily sludge initially crushed by the roller crusher at a high speed. Collision, under the action of energy generated by supersonic speed, the oily sludge raw material (median diameter = 1563 μm detected by laser particle size analyzer) is broken into fine particles (median diameter = 47 μm), and enters the main reaction device 1;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com