Steel plate heat treatment protective agent and heat treatment method

A heat treatment method and heat treatment protection technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as the inability to realize the controllable operation of ultra-high hardness wear-resistant plates, and the inability to solve the problem of uniform cooling of steel plates, etc. The effect of small shape deformation and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

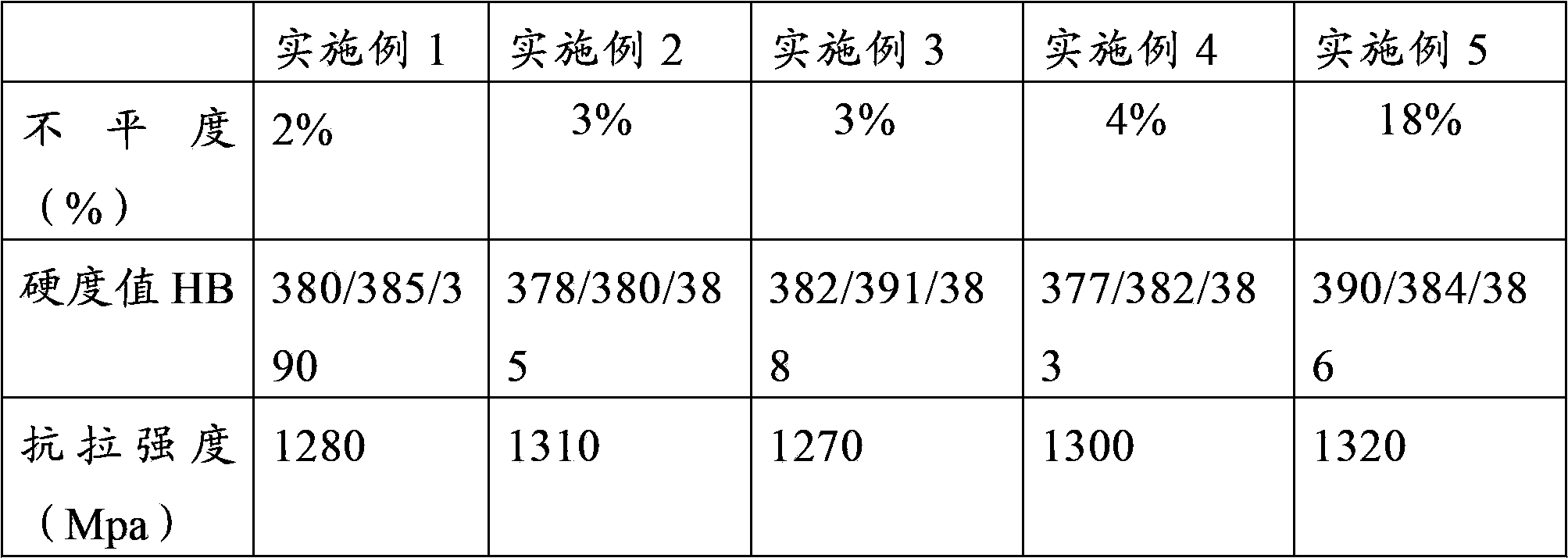

Examples

Embodiment 1

[0067] 1. Rolling: Before rolling, cut a gap of 25 mm in the middle of the two opposite long sides of the billet, hot-roll or cold-roll the billet at 950 ° C, and roll each billet into two steel plates way of rolling.

[0068] 2. Shot blasting: Select a rolled NM360 steel plate of 30*1800*5600mm, and use a shot blasting machine to blast it.

[0069] 3. Preparation and coating of heat treatment protective agent: Stir and mix the precipitated barium sulfate powder and water according to the ratio of 1:1, and then use the manual coating method to evenly smear on the upper and lower surfaces of the steel plate. The thickness of the coating film is about 2mm.

[0070] 4. Heat treatment:

[0071] (1) The temperature setting of the open flame normalization furnace: the length of the open flame normalization furnace is 50m, except for the first and last 1m, it is divided into six sections of heat treatment, each section is 8m in length, and the furnace temperature settings of each s...

Embodiment 2

[0079] 1. Rolling: Before rolling, cut a gap of 20mm in the middle of the two opposite long sides of the steel billet, hot-roll or cold-roll the steel billet at 950°C, and roll each billet into two steel plates way of rolling.

[0080] 2. Shot blasting: Select a rolled NM360 steel plate of 30*1800*5600mm, and use a shot blasting machine to blast it.

[0081] 3. Preparation and coating of heat treatment protective agent: Stir and mix the precipitated barium sulfate powder and water according to the ratio of 0.95:1.05, and then use the manual coating method to evenly smear on the upper and lower surfaces of the steel plate. The thickness of the coating film is about 3mm.

[0082] 4. Heat treatment:

[0083] (1) The temperature setting of the open flame normalization furnace: the length of the open flame normalization furnace is 50m, except for the first and last 1m, it is divided into six sections of heat treatment, each section is 8m in length, and the furnace temperature set...

Embodiment 3

[0091] 1. Rolling: Before rolling, cut a gap of 15mm in the middle of the two opposite long sides of the steel billet, hot-roll or cold-roll the steel billet at 950°C, and roll each billet into two steel plates way of rolling.

[0092] 2. Shot blasting: Select a rolled NM360 steel plate of 30*1800*5600mm, and use a shot blasting machine to blast it.

[0093] 3. Preparation and coating of heat treatment protective agent: Stir and mix the precipitated barium sulfate powder and water according to the ratio of 1.1:0.9, and then apply it evenly on the upper and lower surfaces of the steel plate by hand. The thickness of the coating film is about 2.5mm.

[0094] 4. Heat treatment:

[0095] (1) The temperature setting of the open flame normalization furnace: the length of the open flame normalization furnace is 50m, except for the first and last 1m, it is divided into six sections of heat treatment, each section is 8m in length, and the furnace temperature settings of each section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com