Ellipsoid-based reflecting lighting confocal measuring device

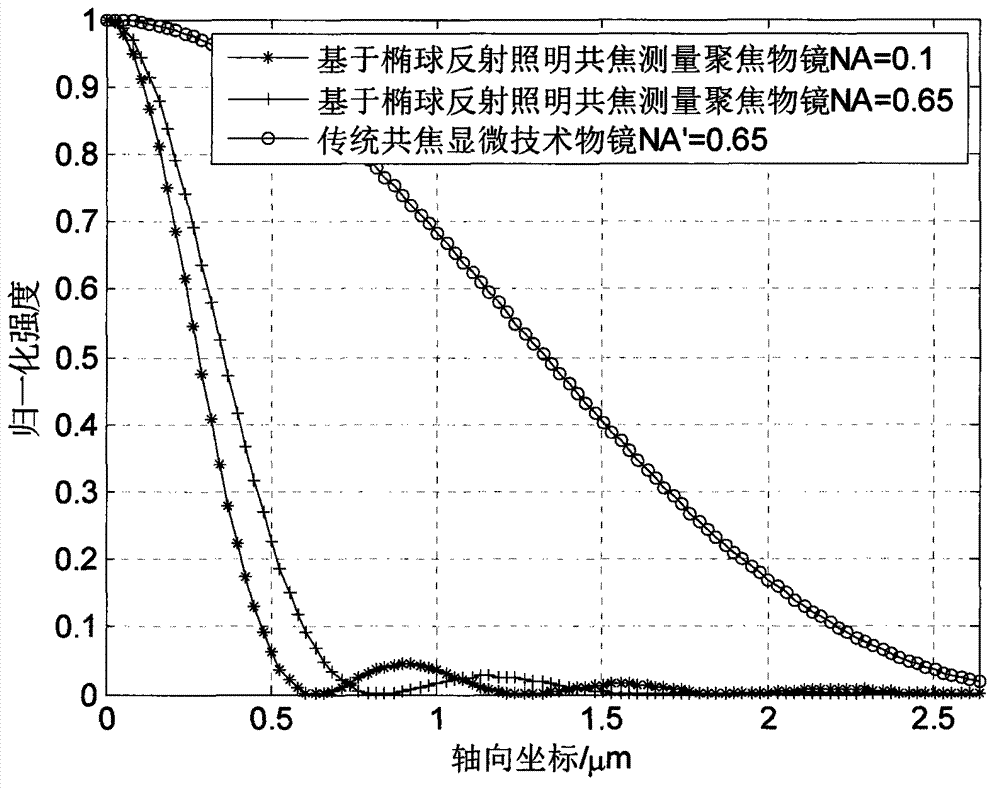

A measuring device and ellipsoid technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of high difficulty of lighting sources, achieve the effect of improving axial resolution and lateral resolution, and increasing numerical aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

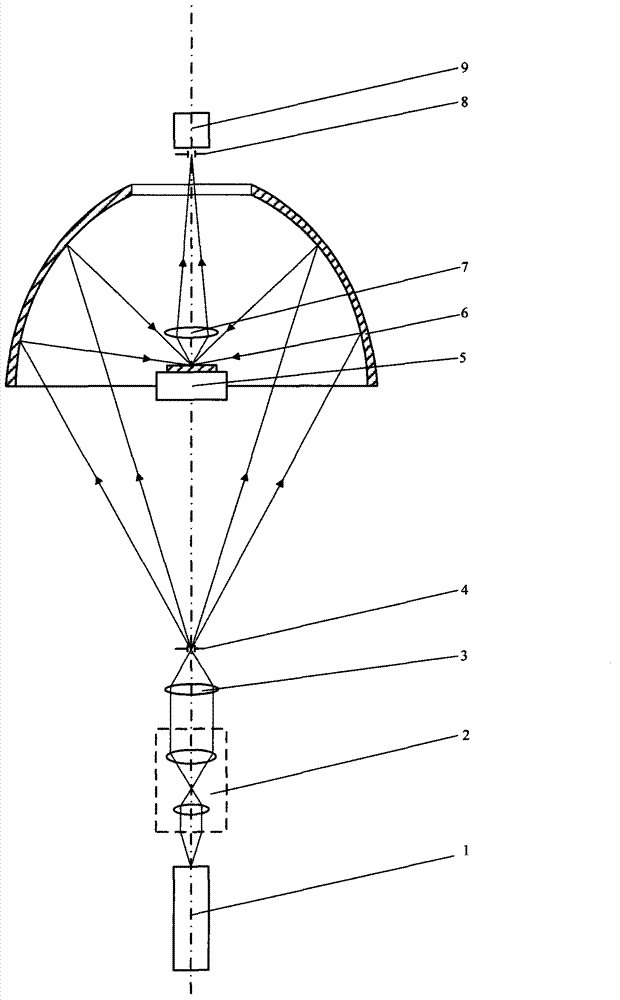

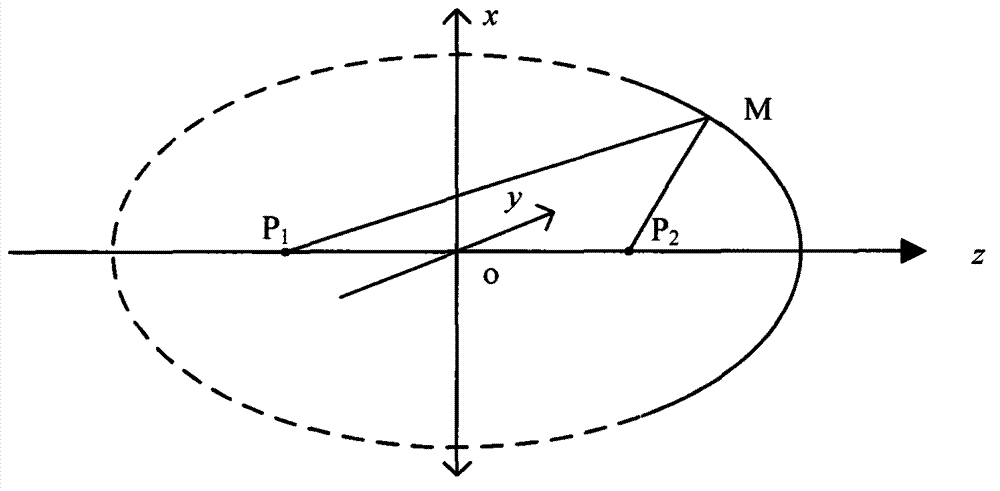

[0014] A confocal measurement device based on ellipsoid reflection illumination includes a laser 1, a collimating beam expander 2 sequentially arranged on the direct light path of the laser 1, a large numerical aperture focusing objective 3, a pinhole 4, a three-dimensional micro-displacement stage 5, Focusing objective lens 7, detection pinhole 8 and detector 9; on the direct light path of the laser 1, an ellipsoid mirror 6 is arranged between the focusing objective lens 7 and the detection pinhole 8, and the far focus of the ellipsoid mirror 6 is located at The pinhole 4 position, the near focus is on the sample surface placed on the three-dimensional micro-displacement stage 5 .

[0015] When measuring work:

[0016] The first step is to illuminate the sample under test.

[0017] like figure 1 As shown, the laser 1 emits a parallel probe beam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com