Laser-electromagnetic ultrasonic nondestructive testing system

An electromagnetic ultrasonic and non-destructive testing technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as easy missed detection, and achieve the effects of increasing magnification, improving sensitivity, and eliminating electrical noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

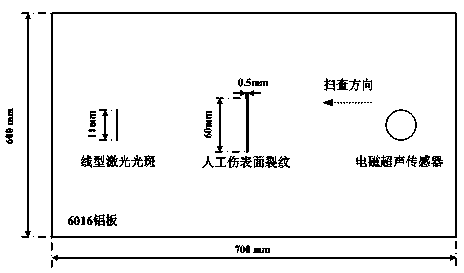

[0024] The principle and features of the patent of the present invention will be described below in conjunction with the accompanying drawings. The example given is the test result of the aluminum plate (grade 6016).

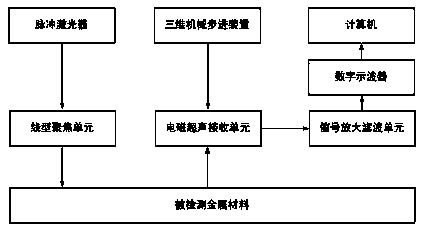

[0025] figure 1 It is a schematic diagram of a laser-electromagnetic ultrasonic nondestructive testing system with high lift-off distance. First, the pulse laser, three-dimensional mechanical stepping device, electromagnetic ultrasonic receiving unit, signal amplification and filtering unit, digital oscilloscope and computer are electrically connected in sequence, and the electromagnetic ultrasonic receiving unit is fixed on the three-dimensional mechanical stepping device. Calibrate the positions of the pulsed laser and the linear focusing unit so that they are placed concentrically. Adjust the position of the cylindrical lens in the linear focusing unit so that the distance between the aluminum plate and the cylindrical lens is 200 mm.

[0026] figure 2 A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com