Preparation method and application of compound positive pole of microbial fuel cell

A composite anode and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limiting microbial fuel cell technology, high cost of raw materials, and low output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a microbial fuel cell composite anode, the steps are as follows:

[0025] 1) Combine 902.5mg activated carbon powder with 47.5mg Fe 3 o 4 Mix evenly to obtain a mixed material;

[0026] 2) Add 25 mL of absolute ethanol (20 mg in mass) to the above mixture and disperse evenly, heat the ethanol in a water bath to slightly boil, then add 35 microliters of 60% polytetrafluoroethylene aqueous solution (polytetrafluoroethylene) drop by drop. The quality of tetrafluoroethylene is 50 mg) to break the emulsion, stir the reactant into a ball, and then roll it into a film;

[0027] 3) Cover the surface of the above-mentioned roll-pressed film-forming material with a layer of stainless steel mesh as the current collector and carrier, roll-form it, and cut it into a certain shape according to the need to make a composite anode.

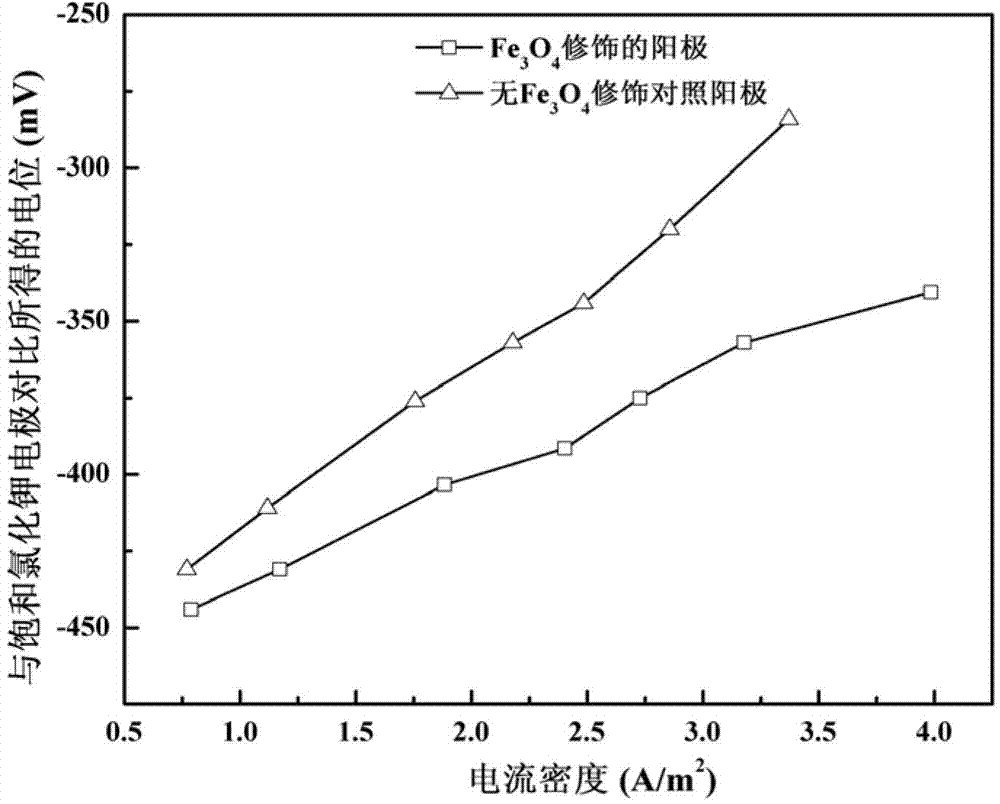

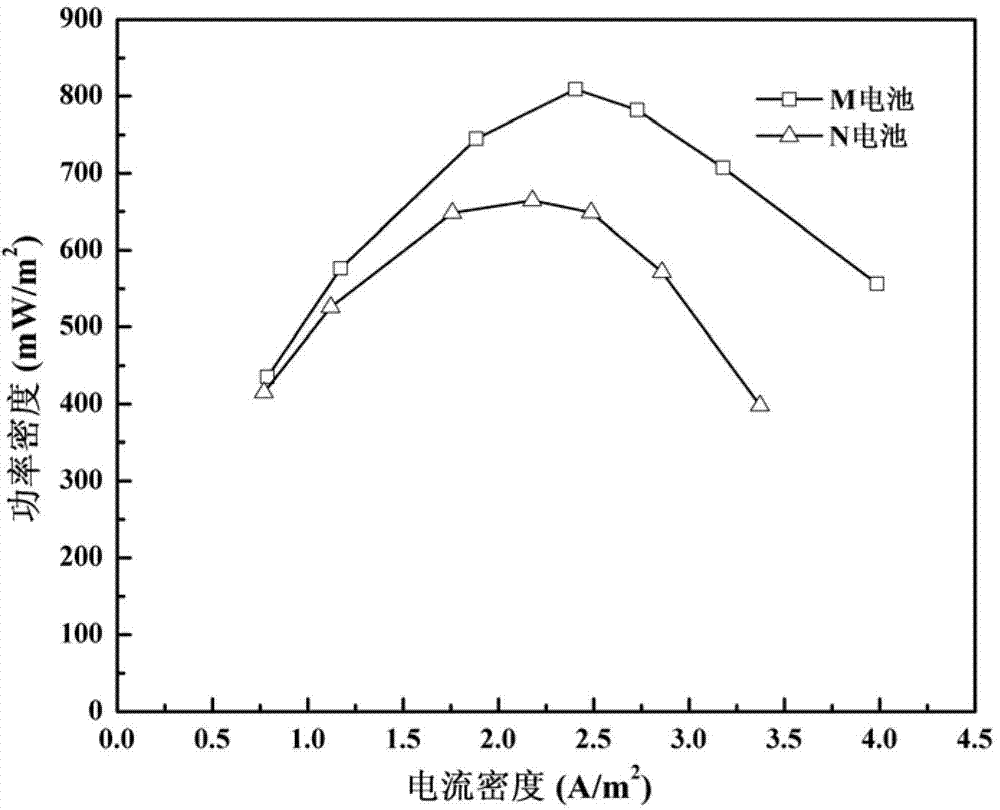

[0028] The composite anode prepared by the above method and the air cathode coated with Pt / C constitute a single-chamber microbia...

Embodiment 2

[0031] A method for preparing a microbial fuel cell composite anode, the steps are as follows:

[0032] 1) Combine 902.5 mg activated carbon powder with 47.5 mg α-FeOOHFe 3 o 4 Mix evenly to obtain a mixed material;

[0033] 2) Add 25 mL of absolute ethanol (20 mg in mass) to the above mixture and disperse evenly, heat the ethanol in a water bath to slightly boil, then add 35 microliters of 60% polytetrafluoroethylene aqueous solution (polytetrafluoroethylene) drop by drop. The quality of tetrafluoroethylene is 50 mg) to break the emulsion, stir the reactant into a ball, and then roll it into a film;

[0034] 3) Cover the surface of the above-mentioned roll-pressed film-forming material with a layer of stainless steel mesh as the current collector and carrier, roll-form it, and cut it into a certain shape according to the need to make a composite anode.

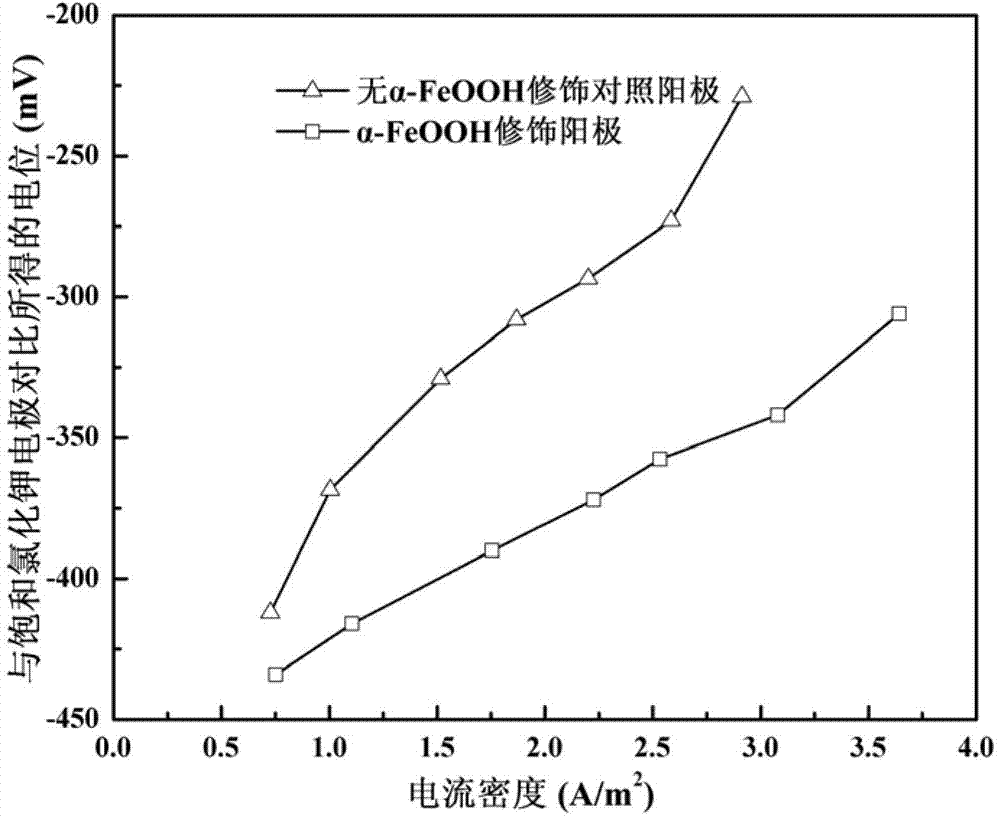

[0035] The composite anode prepared by the above method and the air cathode coated with Pt / C constitute a single-chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com