Plant and method for producing finely divided fuels from solid or pasty energy raw materials by means of roasting and pulverizing

A roasting and energy technology used in roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

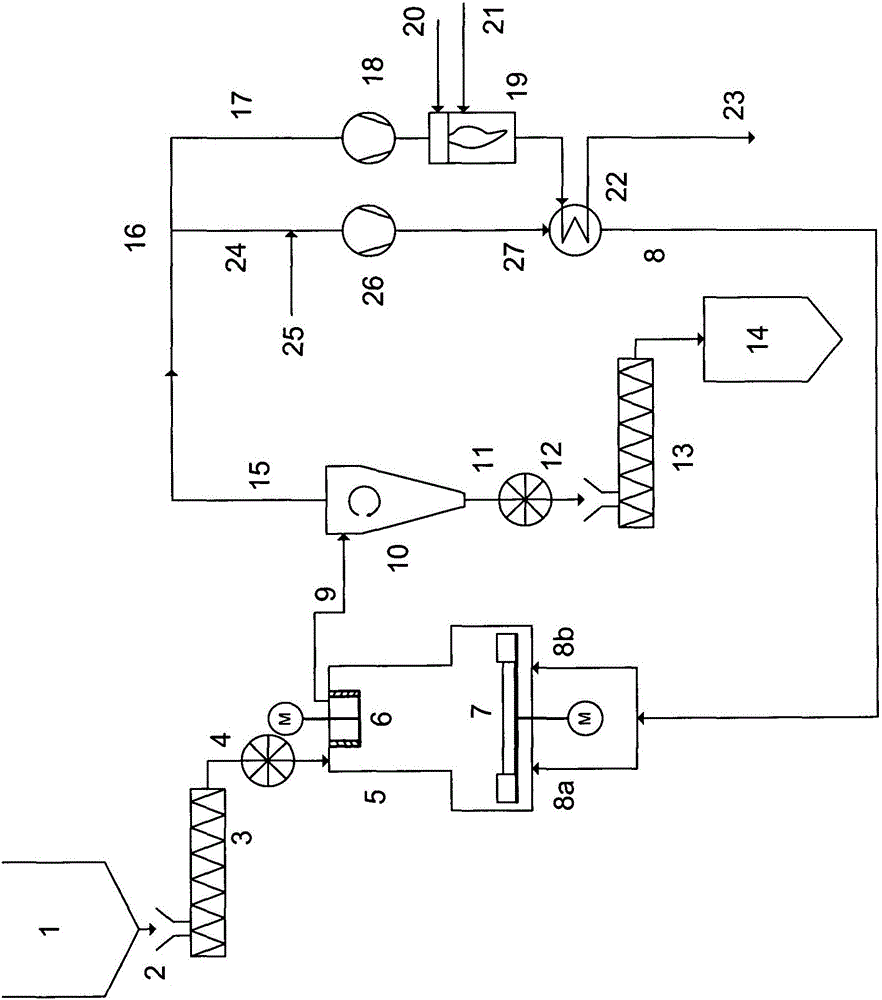

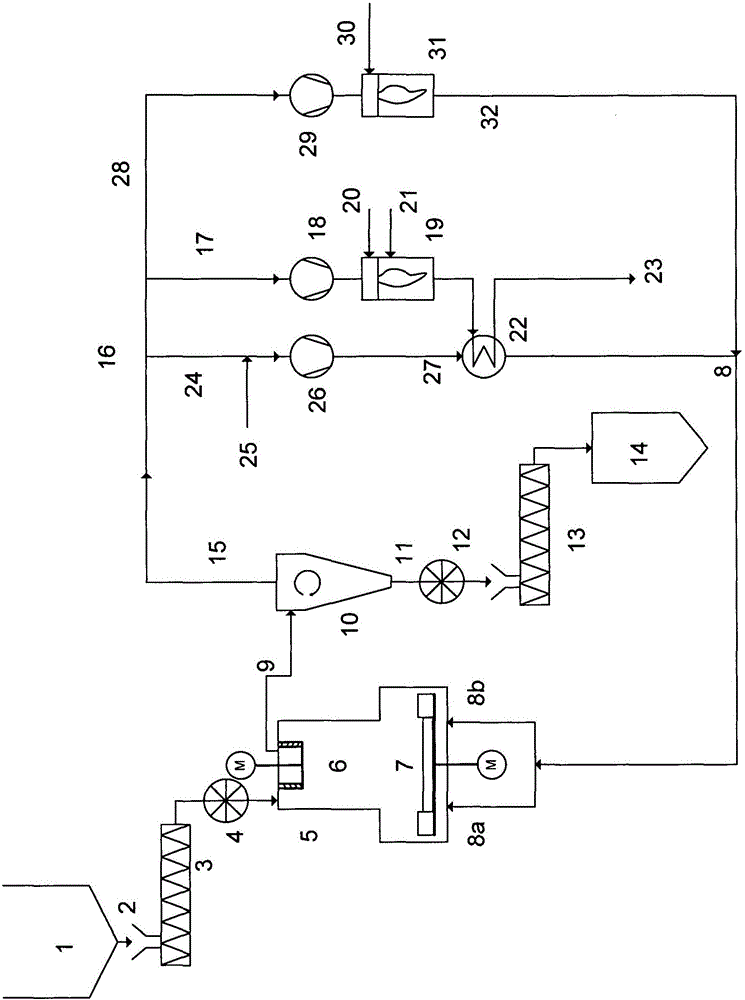

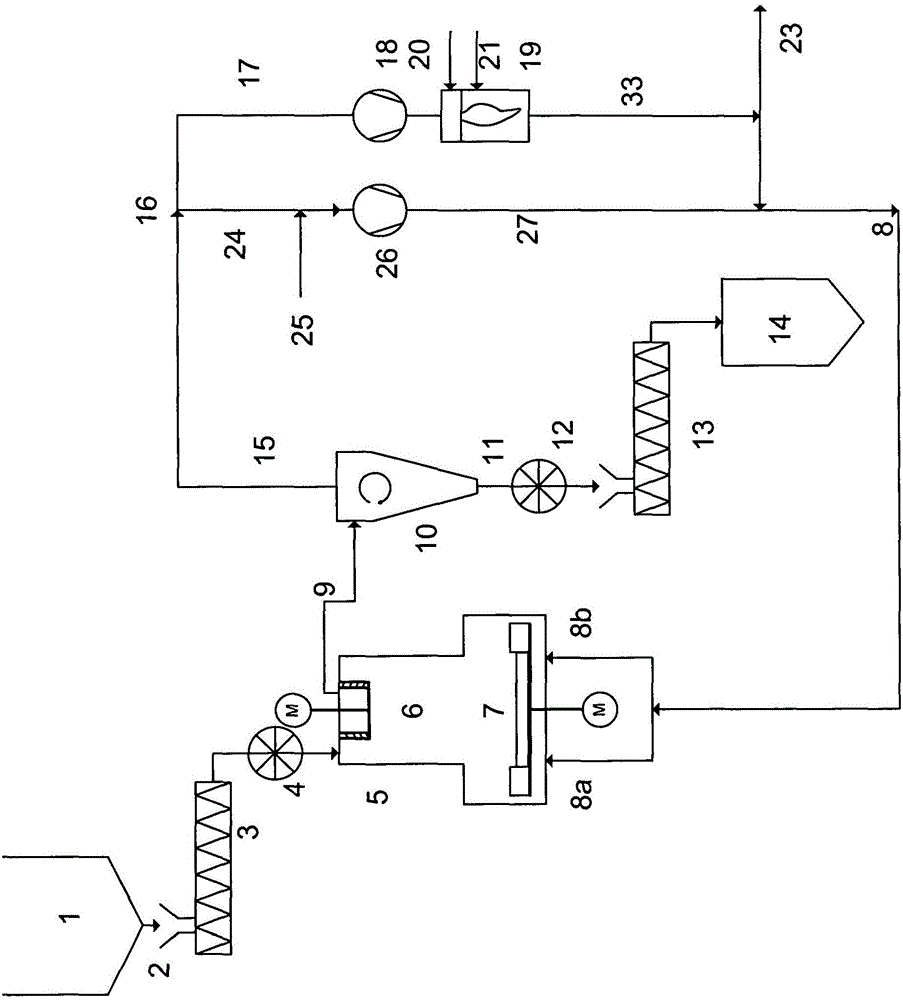

[0050] Biomass 2 is conveyed from raw material tank 1 into impact reactor 5 via screw conveyor 3 and star wheel feeder 4 . Here it is pulverized by the rotor 7 . Calcination gas is fed in the bottom of the impactor 5 in the form of hot recirculation gases 8a and 8b. The pulverized, dried, calcined particles 11 are discharged from the impact reactor 5 together with the gas stream 9 through a sifter 6, preferably a motor-driven rotary sieve, and are directed to the particle separator 10 (shown here as a centrifugal separator).

[0051] An advantage here is that the use of the sieve 6 allows adjustment of the size of the particles discharged together with the gas flow 9 . It may also be advantageous to dispense with a motor-driven rotary sieve and use screens or perforated plates which allow size control of the solid particles contained in the gas stream 9 .

[0052] Depending on the intended use of the pretreated fuel, the target particle size of the torrefied particles 11 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com