TiO2/Fe2O3 composite hollow microsphere and preparation method thereof

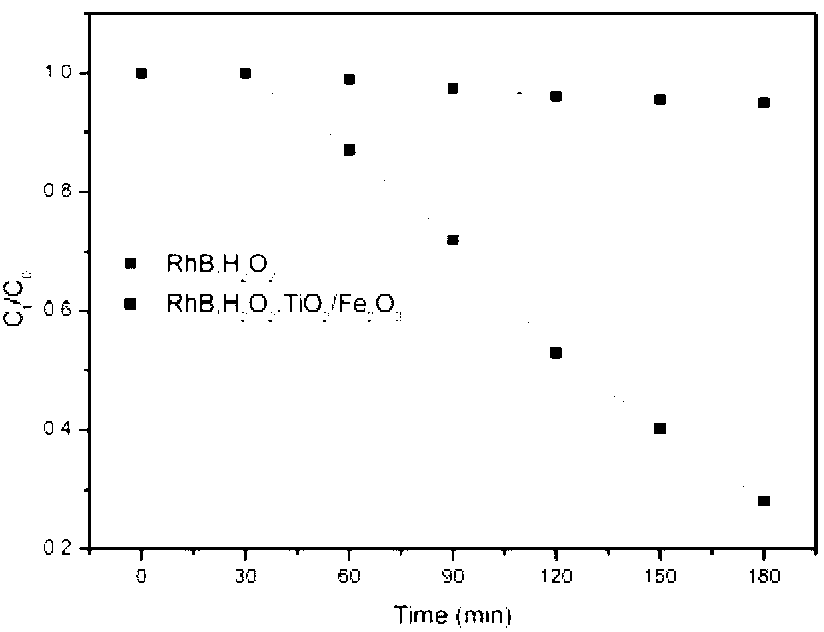

A technology of tio2-fe2o3 and hollow microspheres, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of poor electrical conductivity and limitations, and achieve the effects of low cost, good gas-sensing performance, and good photocatalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

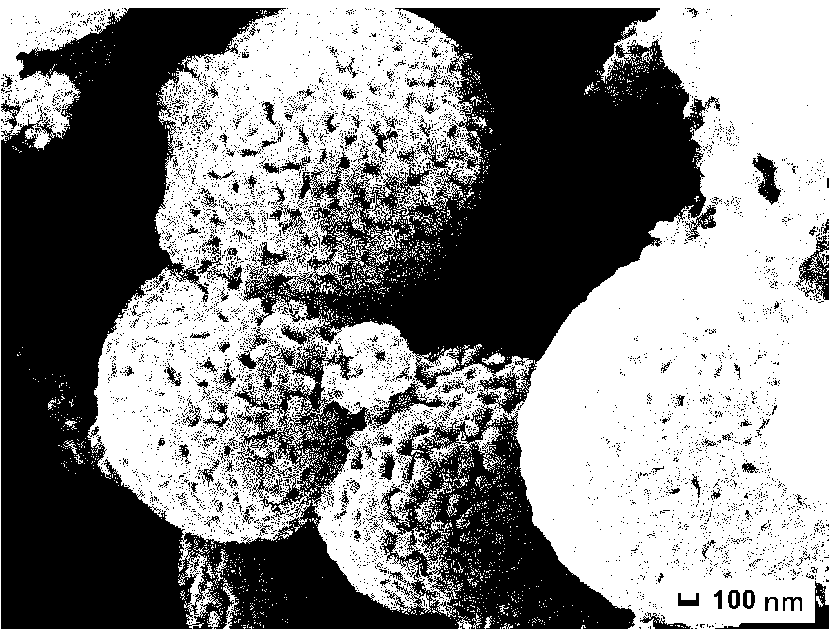

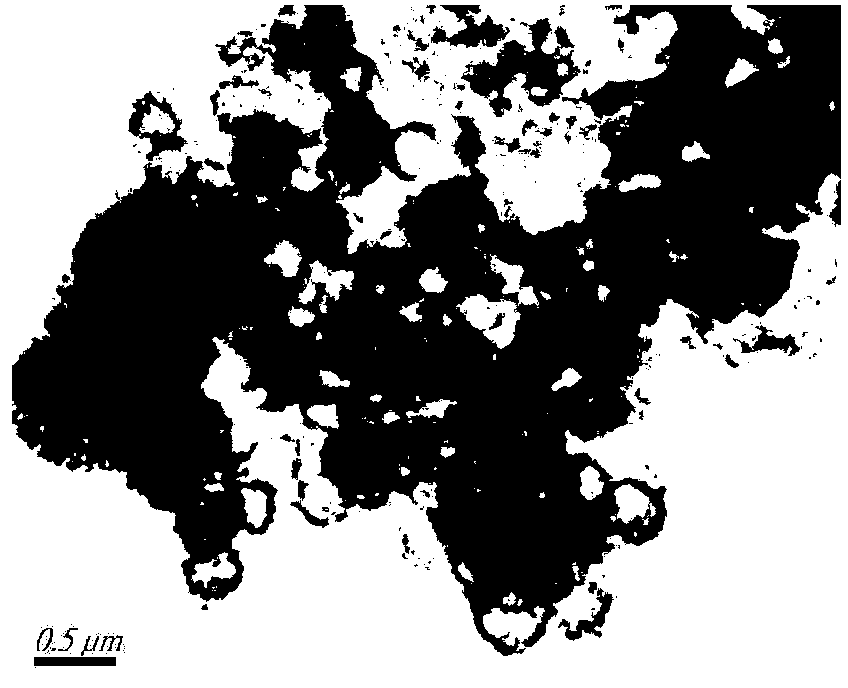

[0032] Dissolve glucose in deionized water to form a 0.15 g / mL solution. The solution was transferred into a stainless steel reaction kettle lined with polytetrafluoroethylene, and hydrothermal reaction was carried out at 160°C for 6 hours. After the reaction, it was centrifuged and dried to obtain a carbon sphere template with a size of 100-1000nm.

[0033] Add a certain quality of ferric chloride into the mixed solution of absolute ethanol and deionized water (volume ratio: 6:1), add urea (the concentration of urea is 0.5mol / L) after it is completely dissolved, and wait until the solution is clarified Finally, add tetrabutyl titanate under stirring, and add the prepared carbon spheres after the solution is mixed evenly. The molar ratio of iron and titanium in the solution is about 2:1. Ultrasonic the solution for 10 minutes in an ultrasonic cleaner, and keep warm at 60°C for 2 sky. Centrifuge, dry, and bake at 450°C for 2 hours to obtain TiO 2 -Fe 2 o 3 Composite microsp...

Embodiment 2

[0035] Dissolve glucose in deionized water to form a 0.17 g / ml solution. The solution was transferred into a stainless steel reaction kettle lined with polytetrafluoroethylene, and hydrothermal reaction was carried out at 180°C for 4 hours. After the reaction, it was centrifuged and dried to obtain a carbon sphere template with a size of 100-1000nm.

[0036] Add a certain quality of ferric chloride into the mixed solution of absolute ethanol and deionized water (volume ratio: 6:2), add urea (the concentration of urea is 0.8mol / L) after it is completely dissolved, and wait for the solution to be clarified Finally, add tetrabutyl titanate under stirring, and add the prepared carbon spheres after the solution is mixed evenly. The molar ratio of iron and titanium in the solution is about 2:2. Ultrasonic the solution for 10 minutes in an ultrasonic cleaner, and keep warm at 70°C for 2 sky. Centrifuge, dry, and bake at 500°C for 1 hour to obtain clathrate TiO 2 -Fe 2 o 3 Composi...

Embodiment 3

[0038] Dissolve glucose in deionized water to form a 0.30 g / mL solution. The solution was transferred into a stainless steel reaction kettle lined with polytetrafluoroethylene, and hydrothermal reaction was carried out at 170°C for 8 hours. After the reaction, it was centrifuged and dried to obtain a carbon sphere template with a size of 100-1000nm.

[0039] Add a certain quality of ferric chloride into the mixed solution of absolute ethanol and deionized water (volume ratio 6:3), and add urea after it is completely dissolved (the concentration of urea is 1mol / L), and the solution is clarified , add tetrabutyl titanate under stirring, mix the solution evenly and add the prepared carbon spheres, the molar ratio of iron and titanium in the solution is about 2:3, sonicate the solution in an ultrasonic cleaner for 10 minutes, and keep it warm at 80°C for 2 days . Centrifuge, dry, and bake at 470°C for 4 hours to obtain clathrate TiO 2 -Fe 2 o 3 Composite hollow microspheres, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com