Preparation method of Ag2S/Ag3PO4 composite photocatalyst

A photocatalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

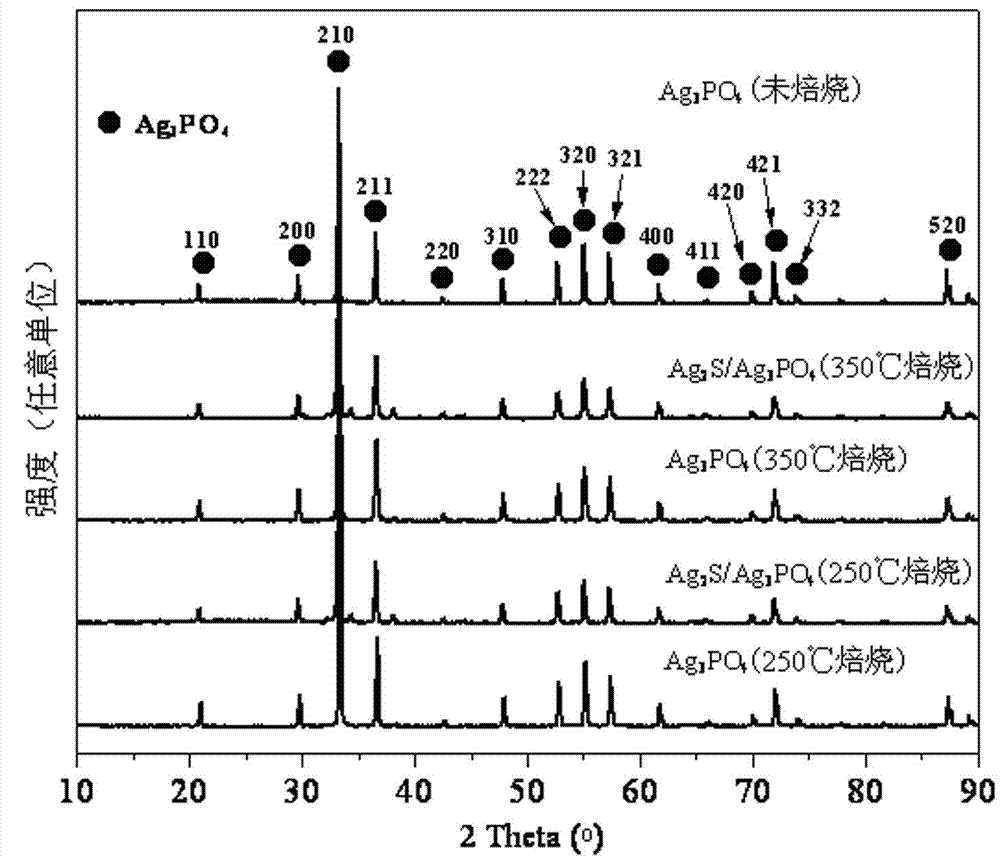

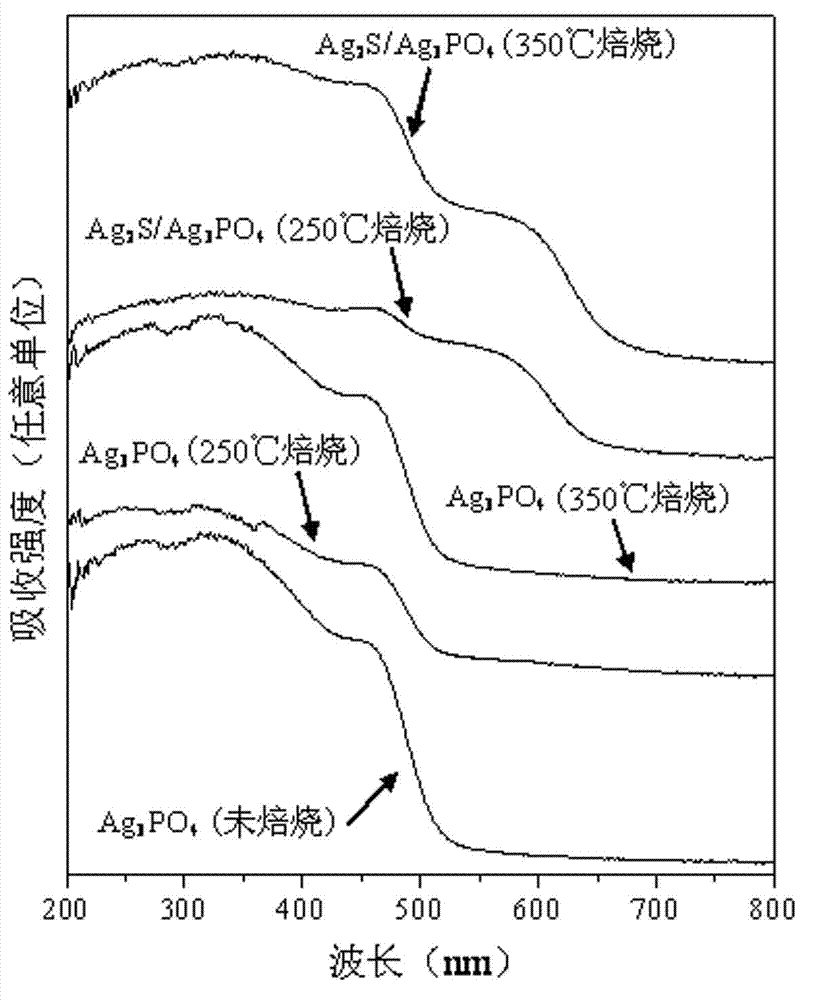

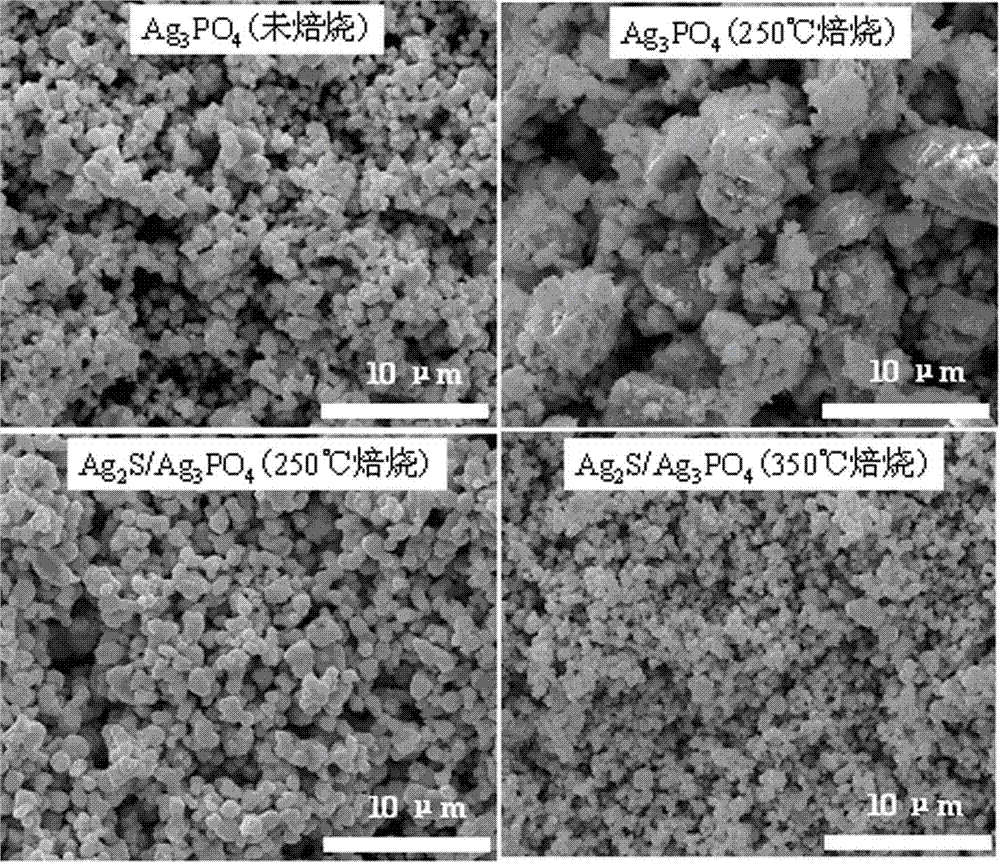

[0015] (1) Ag 3 PO 4 The preparation process of the photocatalyst is as follows:

[0016] At room temperature, the AgNO 3 Aqueous solution, ammonia water, NaH 2 PO 4 Stir the aqueous solution together, then wash and dry the obtained product, take out a part of the product, and roast it at different temperatures. The unroasted and roasted products are collectively referred to as Ag 3 PO 4 Photocatalyst, Ag 3 PO 4 The photocatalyst is reserved for the experiment.

[0017] (2) Ag 2 The preparation process of S photocatalyst is as follows:

[0018] At room temperature, the AgNO 3 Aqueous solution, Na 2 The S aqueous solution is stirred together, and then the obtained product is washed and dried, and a part of the product is taken out, which is roasted at different temperatures. The unroasted and roasted products are collectively referred to as Ag 2 S photocatalyst, Ag 2 The S photocatalyst is reserved for the experiment.

[0019] (3) Ag of the present invention 2 S / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com