Synthetic sludge fuel and preparation method thereof

A technology for synthesizing fuel and sludge, which is applied in the field of sludge synthesis as fuel and formula ratio of sludge synthesis fuel, which can solve the problem of unfavorable consumption of water-containing sludge, saving raw coal, high raw coal content of sludge synthesis fuel, and utilization of water-containing sludge Low efficiency and other problems, to achieve the effect of excellent combustion conditions and environmental protection performance, small footprint, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

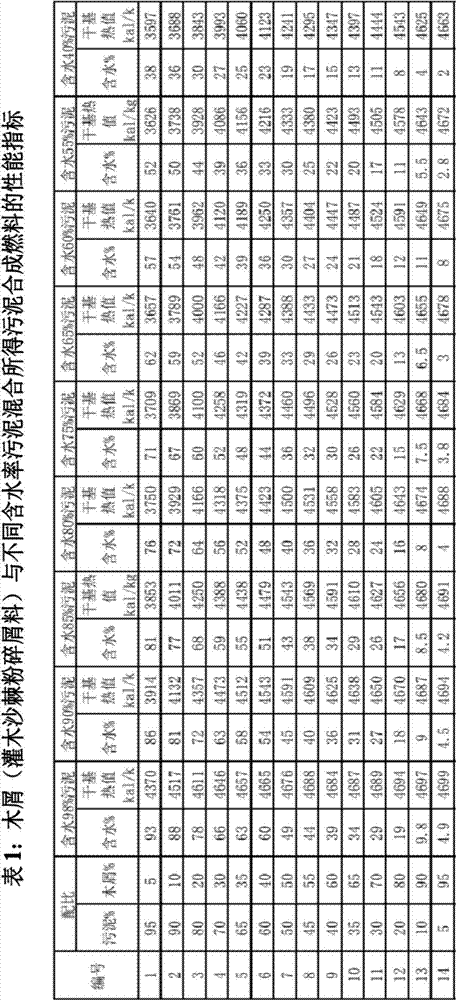

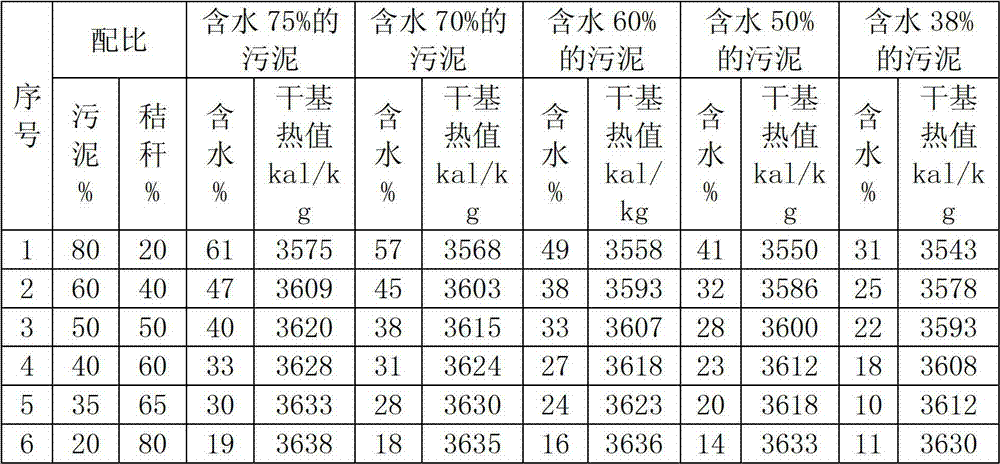

[0022] The mechanism of the present invention is as follows: in the sludge synthetic fuel, the sludge contains a large amount of organic matter, and the volatile matter on a dry basis is as high as 60-70%, which can be used as fuel; but the sludge contains a large amount of water, and the untreated sludge of the sewage treatment plant The water content is generally 80-98%, and the sludge is used as fuel, and the water content needs to be reduced. There are many ways to dehydrate, including drying, drying, mechanical dehydration, and dehydration by adding a dehydrating agent.

[0023] In order to avoid air pollution caused by sludge synthetic fuel, sludge should be deodorized and sterilized, and the treatment methods can be chemical or physical. Chemical method, that is, adding a sludge stabilizer, such as lime, etc.; physical method, including drying and drying, using medium and high temperature of 200°-350° or sunlight for deodorization and sterilization, and drying can use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com