Spatial three-dimensional layout fast composite brush-plated diamond wire saw device

A diamond wire saw, three-dimensional technology, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of large area, difficult and harmful gas centralized treatment, large area of electroplating tank, etc., to reduce the area occupied area, speeding up the efficiency of brush plating, and the effect of strong production adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Such as Figure 1-6 shown.

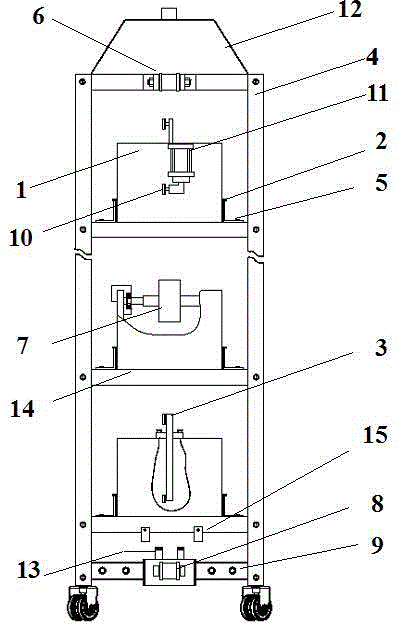

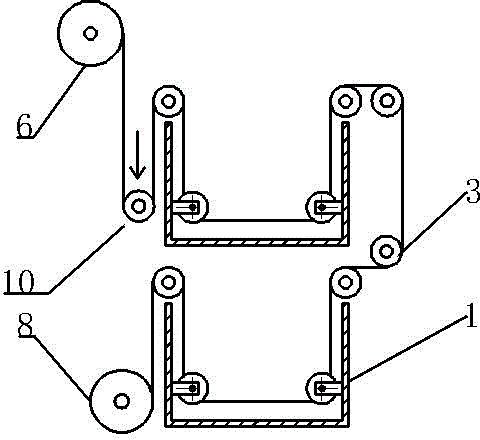

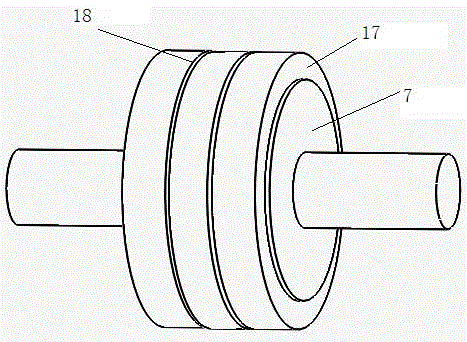

[0032] A space three-dimensional layout fast composite brush-plated diamond wire saw device, which includes at least three electroplating tanks 1 (cleaning tank, activation tank and brush plating tank) and a bracket 4, such as figure 1 As shown, the outer bottom ends of the two parallel side walls of the electroplating tank 1 are equipped with sliders 2, and the upper ends of the two parallel side walls are equipped with guide wheels 3; the space of the electroplating tank 1 is vertically distributed on the bracket 4, A guide rail 5 is installed on the bracket 4, and the connection between the electroplating tank 1 and the bracket 4 is realized by the cooperation of the slider 2 and the guide rail 5, as Figure 4 The steel wire 16 is released by the wire feeding wheel 6, and is introduced and drawn out of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com