Coal bed gas multilateral well recovery control stimulation device

A technology for controlling simulation and branch wells, applied in simulators, general control systems, control/regulation systems, etc., can solve the problems of large and small gas production, large liquid supply area, no gas production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

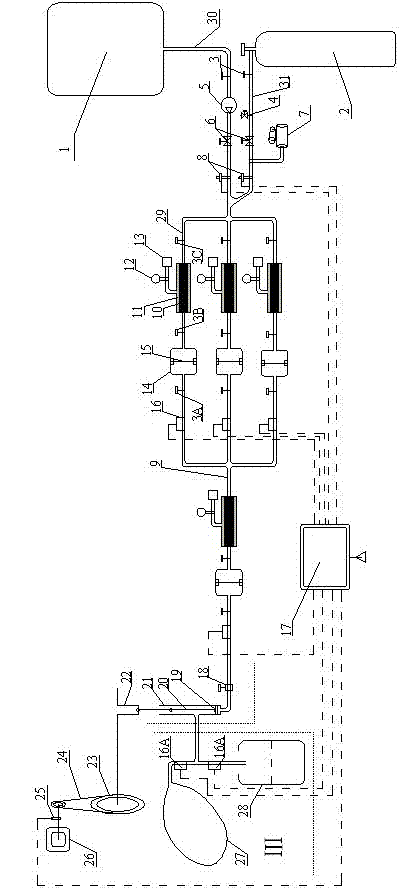

[0021] Depend on figure 1 with figure 2 A coalbed methane branch well drainage control simulation device shown includes a main pipeline 9 and three branch pipelines 29 .

[0022] The front end of the main pipeline 9 is connected to an air extraction device for simulating drainage control, and the front end of the main pipeline 9 is first connected to an air extraction cylinder 21 through a back pressure valve 18, and then the air extraction cylinder 21 is connected to the air extraction device. The side of the air extraction cylinder 21 The wall is also respectively communicated with an air bag 27 and a water collection bottle 28 through two connecting pipes, and a flow meter 16A is arranged on the connecting pipes. Described air extraction device is plunger type air extraction device, and plunger type air extraction device comprises the plunger that is slidably connected in the air extraction cylinder 21 and the power unit that connects plunger, and described power unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com