Photoelectric detection lamination, semiconductor ultraviolet detector and manufacturing method of semiconductor ultraviolet detector

An ultraviolet detector and photoelectric detection technology, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high manufacturing cost and low photoelectric efficiency, achieve enhanced photogenerated current, reduce manufacturing cost, and enhance The effect of the photoelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

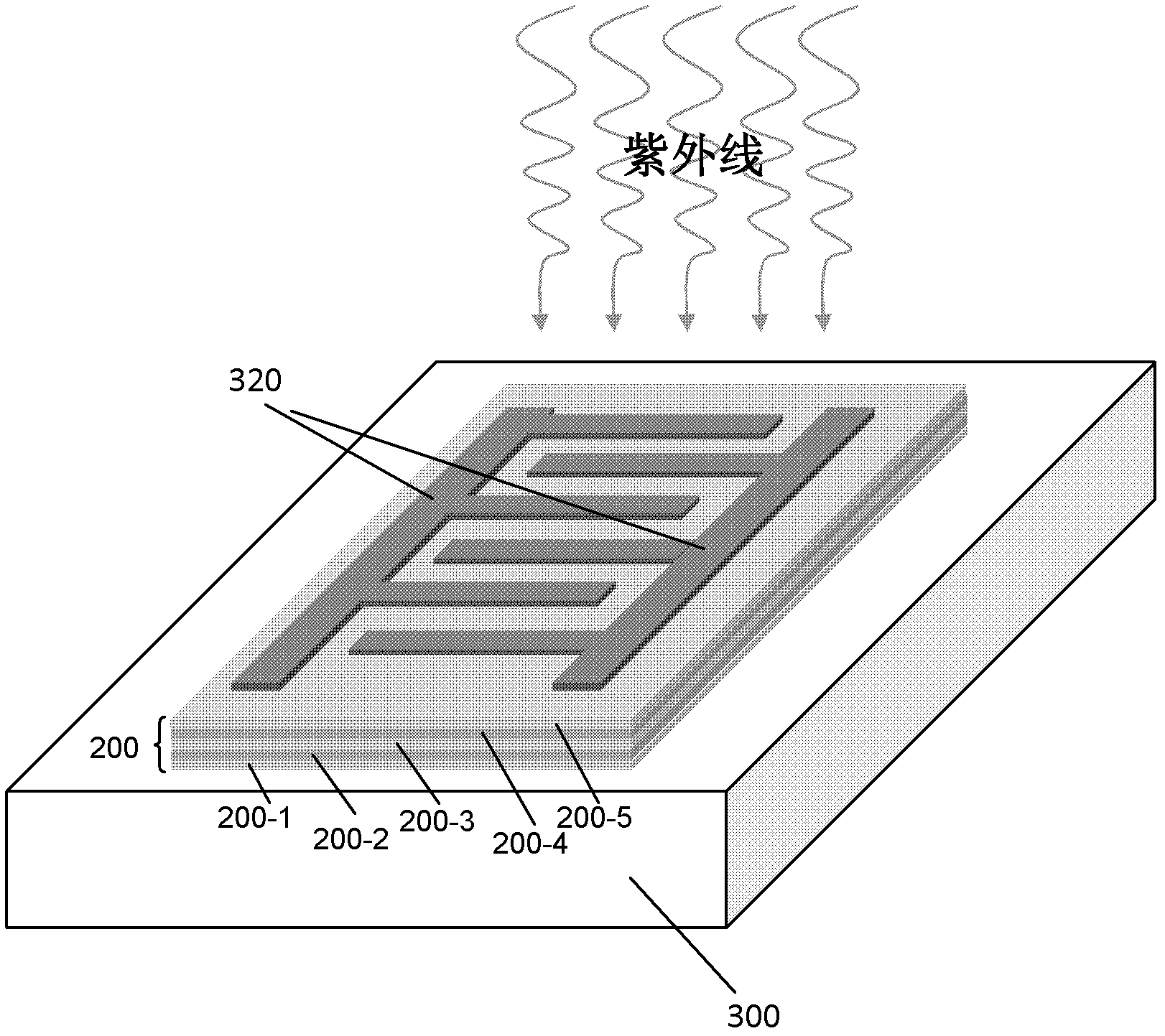

[0052] In this embodiment, a semiconductor ultraviolet detector with an MSM structure of the above-mentioned photodetection stack is provided, referring to image 3 As shown, the detectors include:

[0053] substrate 300;

[0054] a photodetection stack 200 on a substrate 300;

[0055] an electrode 320 on the photodetection stack 200;

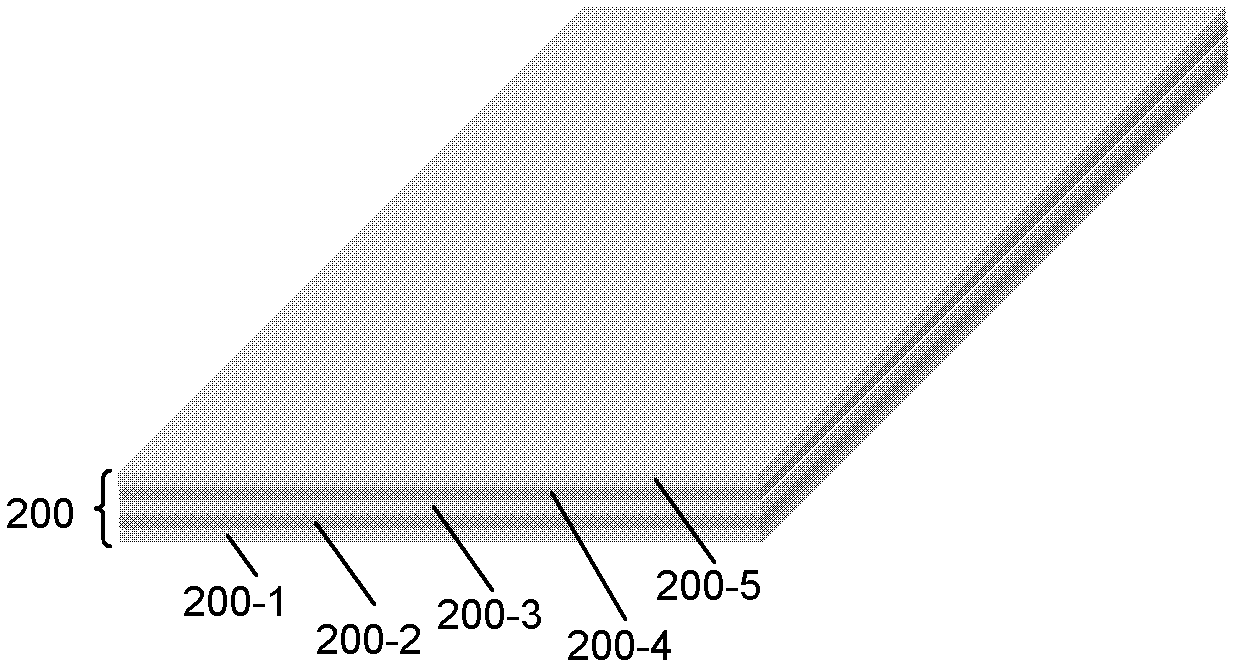

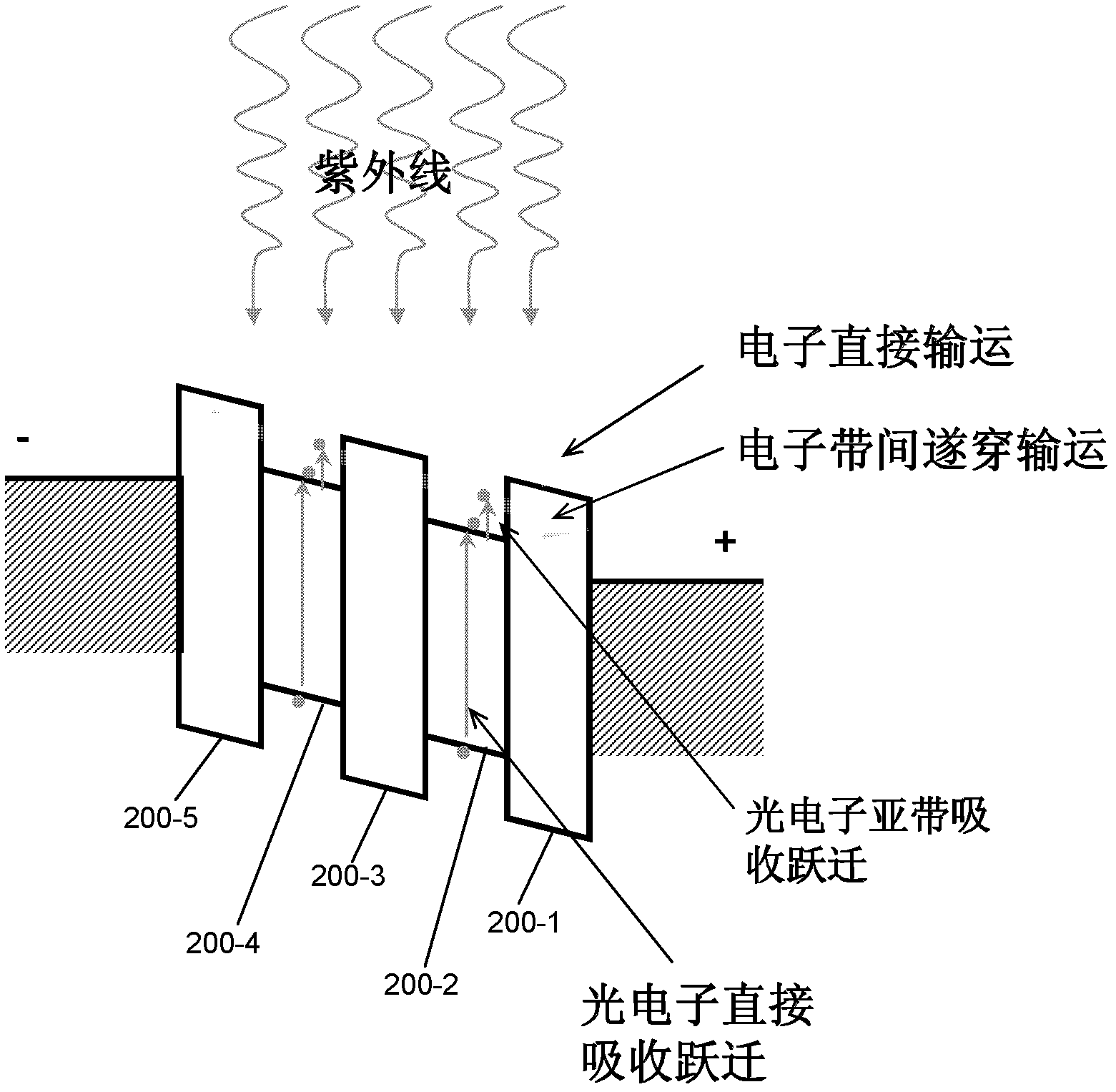

[0056] Wherein, the photodetection stack includes m layers of wide-bandgap amorphous oxide semiconductor layers and n layers of narrow-bandgap amorphous oxide semiconductor layers, and the wide-bandgap amorphous oxide semiconductor layer and narrow-bandgap The amorphous oxide semiconductor layers are arranged alternately, the forbidden band width of the wide bandgap amorphous oxide semiconductor layer is larger than the narrow bandgap amorphous oxide semiconductor layer, m, n≥1 .

[0057] It should be noted that, in this embodiment, all the content of the photodetection stack refers to the description in the above-mentioned photodetection s...

Embodiment 2

[0073] In this embodiment, a semiconductor ultraviolet detector with a TFT structure of the above-mentioned photodetection stack is provided, referring to Figure 4 , the detectors include:

[0074] substrate 300;

[0075] a gate electrode 310 on the substrate 300;

[0076] The gate electrode 310 and the gate insulating layer 312 on the substrate 300 on both sides of the gate electrode;

[0077] the photodetection stack 200 on the gate insulating layer 312;

[0078] Source / drain electrodes 320 on the photodetection stack 200 on both sides of the gate electrode 310;

[0079] Wherein, the photodetection stack includes m layers of wide-bandgap amorphous oxide semiconductor layers and n layers of narrow-bandgap amorphous oxide semiconductor layers, and the wide-bandgap amorphous oxide semiconductor layer and narrow-bandgap The amorphous oxide semiconductor layers are arranged alternately, the forbidden band width of the wide bandgap amorphous oxide semiconductor layer is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com