Chromium-base catalyst for synthesizing alpha-tetralone by tetrahydronaphthalene and preparation method thereof

A technology of chromium-based catalyst and tetralone, which is applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve the problems of difficult recovery and recycling, low activity, etc., and achieve easy reuse, The effect of simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

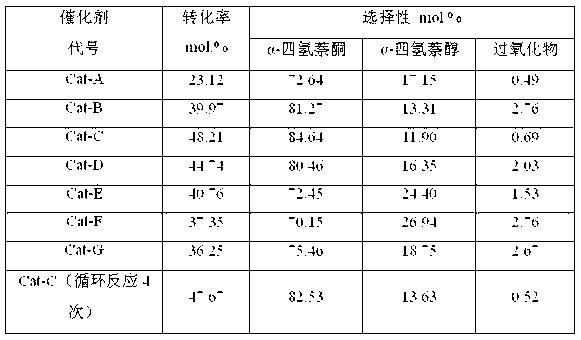

Embodiment 1

[0016] Embodiment 1: with containing 0.1762 gram Cr (NO 3 ) 3 9H 2 O and 0.0320 g Co(NO 3 ) 2 ·6H 2 1 g of activated alumina with a particle size of 0.35 mm was impregnated with an equal volume of O solution at room temperature for 12 h. After the impregnation, dry at 180°C for 1 hour and bake at 300°C for 1 hour in an air atmosphere to obtain a cobalt-modified chromium-based catalyst, which is designated as Cat-A. The specific composition is shown in Table 1.

Embodiment 2

[0017] Embodiment 2: with containing 0.5238 gram Cr (NO 3 ) 3 9H 2 O and 0.0351 g Cu(NO 3 ) 2 ·3H 2 1 g of activated alumina with a particle size of 0.50 mm was impregnated with an equal volume of O solution at room temperature for 12 h. After impregnation, dry at 120°C for 1 hour and bake at 300°C for 1 hour in an air atmosphere to obtain a copper-modified chromium-based catalyst, which is designated as Cat-B. The specific composition is shown in Table 1.

Embodiment 3

[0018] Embodiment 3: with containing 0.7974 gram Cr (NO 3 ) 3 9H 2 O and 0.0722 g Ce(NO 3 ) 3 ·6H 2 Immerse 1 gram of activated alumina with a particle size of 0.70 mm in an equal volume of O solution at room temperature for 24 h. After impregnation, dry at 80°C for 4 h and bake at 500°C for 4 h in an air atmosphere to obtain a cerium-modified chromium-based catalyst, which is recorded as Cat-C. The specific composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com