Causticizing method and process device for preparing precipitated calcium carbonate by recycling papermaking alkali

A technology for precipitating calcium carbonate and a process device, which is applied in the field of causticizing process devices for preparing precipitated calcium carbonate by recycling alkali in papermaking, can solve the problems of poor shape uniformity and low whiteness of white mud, and achieves easy implementation, high whiteness and granularity. fine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The accompanying drawings and specific implementation methods of the present invention will be further described in detail below. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

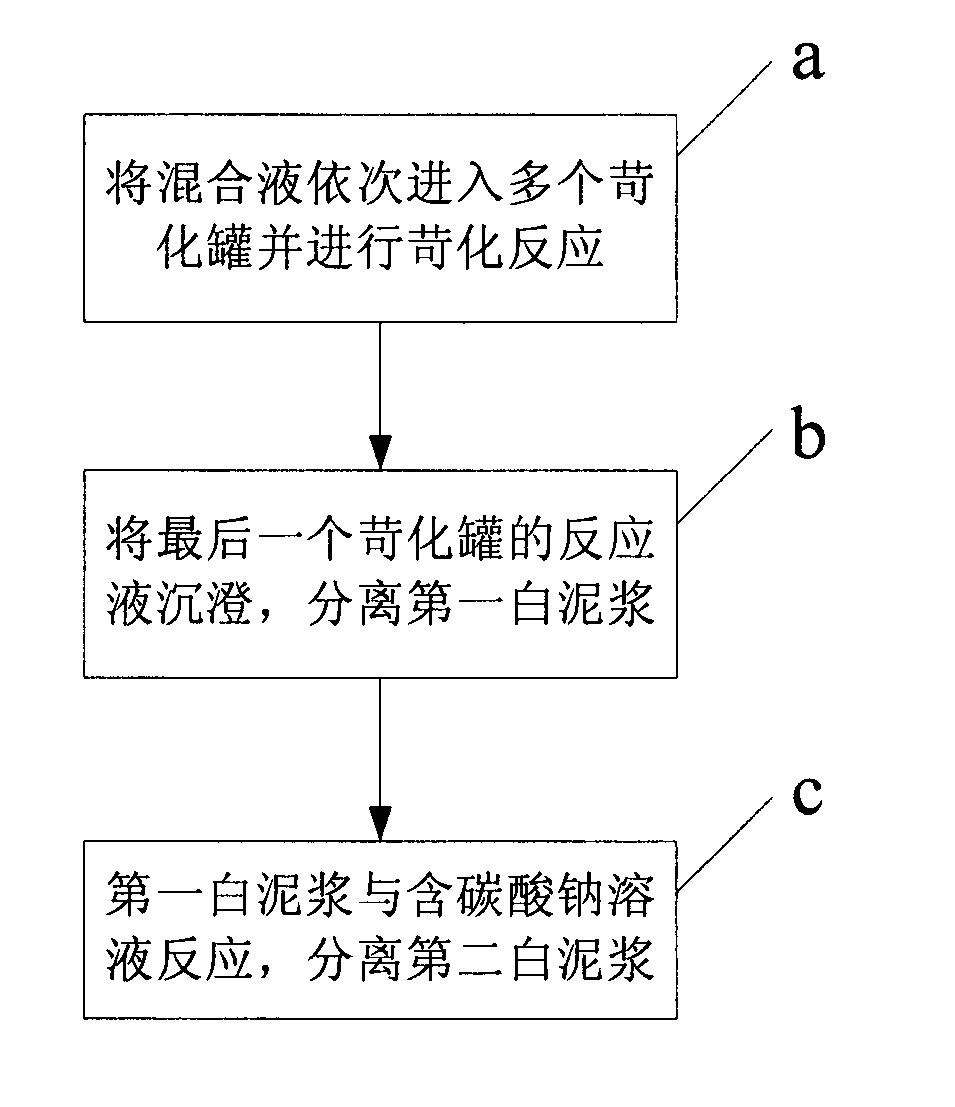

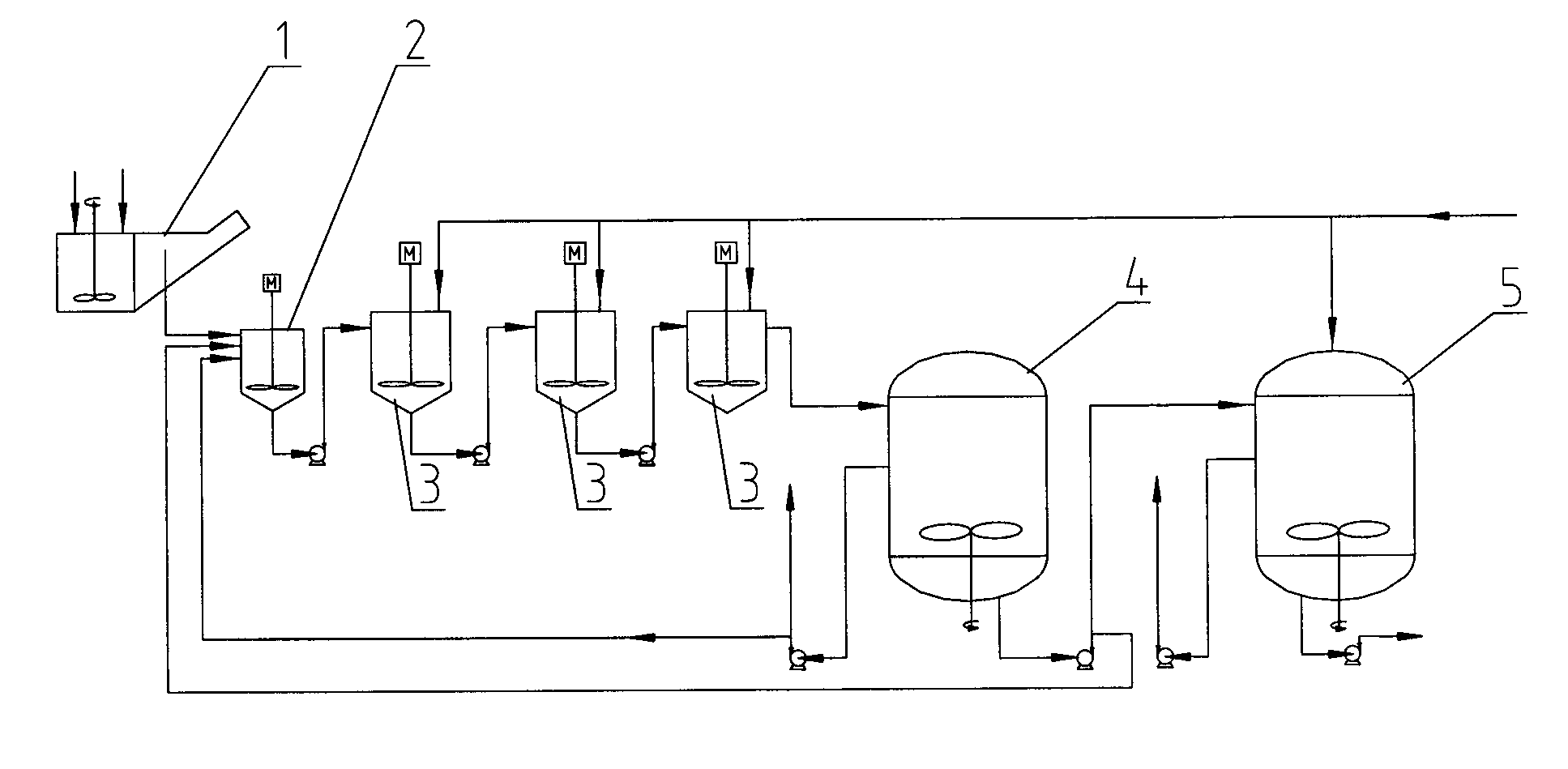

[0032] figure 1 Shown is a flow chart of a causticizing method for preparing precipitated calcium carbonate from papermaking alkali according to an embodiment of the present invention. It can be seen from the figure that the causticizing method includes step a, step b and step c.

[0033] In step a, the present invention will contain Ca(OH) 2 Digestive liquid, NaOH-containing solution and aragonite-type calcium carbonate seed crystals are mixed, and the mixed solution enters multiple causticizing tanks for causticizing reaction in turn, and each causticizing tank is fed with NaOH-containing 2 CO 3 the green liquor;

[0034] Among them, the containing Ca(OH) 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com