Separating and purifying process of isochrysis galbana exopolysaccharide

A technology for the separation and purification of dinoflagellate cells, applied in the field of marine biochemical engineering, can solve the problems of polysaccharide separation and purification, structure identification and physiological activity that have not been reported, and achieve good operability, stable reproducibility, simple and reasonable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

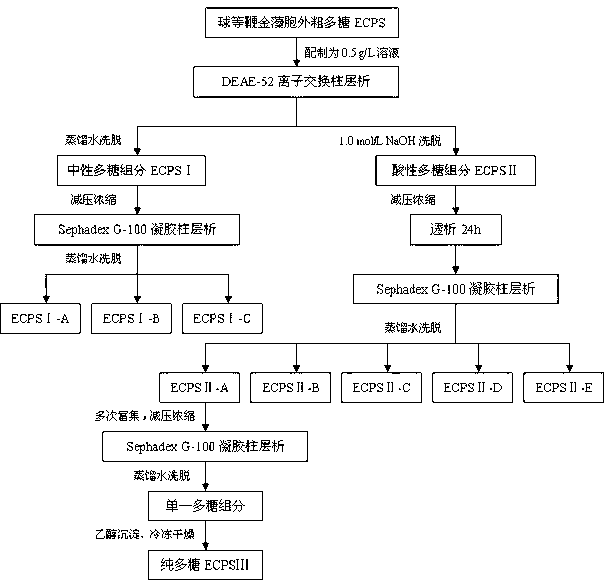

[0022] Embodiment 1, with reference to figure 1 , a separation and purification process of Isochrysis globosa exopolysaccharide, the steps are as follows:

[0023] (1) Select the culture of Isochrysis globosa that has been cultured to the exponential growth stage, centrifuge at 5000 rpm / min for 15 min, take the supernatant, filter it through a 0.22 μm microporous membrane, concentrate under reduced pressure at 45°C; freeze-dry After that, a white powdery extracellular substance was obtained;

[0024] (2) Take extracellular substances and add them to distilled water, the mass ratio of distilled water to extracellular substances is 15:1. After mixing evenly, adjust the pH to 9.0 with 0.5 M NaOH, and extract in a water bath at 70°C for 240 min; the extraction is completed Afterwards, centrifuge at 5000 rpm / min for 5 min, take the supernatant and add trichloroacetic acid with a mass concentration of 3%, let stand at 4 °C for 4 h, centrifuge at 5000 rpm / min for 5 min, and discard...

Embodiment 2

[0028] Embodiment 2, with reference to figure 1 , a separation and purification process of Isochrysis globosa exopolysaccharide, the steps are as follows:

[0029] (1) Select the culture of Isochrysis globosa that has been cultured to the exponential growth stage, centrifuge at 5000 rpm / min for 15 min, take the supernatant, filter it through a 0.22 μm microporous membrane, concentrate under reduced pressure at 45°C; freeze-dry After that, a white powdery extracellular substance was obtained;

[0030] (2) Take extracellular substances and add them to distilled water, the mass ratio of distilled water to extracellular substances is 15:1. After mixing evenly, adjust the pH to 9.0 with 0.5 M NaOH, and extract in a water bath at 70°C for 240 min; the extraction is completed Afterwards, centrifuge at 5000 rpm / min for 5 min, take the supernatant and add trichloroacetic acid with a mass concentration of 3%, let stand at 4 °C for 4 h, centrifuge at 5000 rpm / min for 5 min, and discard...

Embodiment 3

[0034] Embodiment 3, the separation and purification process experiment 1 of Isochrysis globosa exopolysaccharide, the steps are as follows:

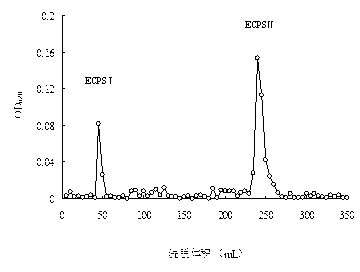

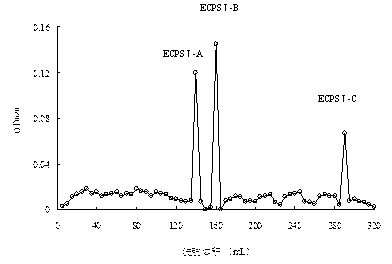

[0035] Weigh 0.5 g of the extracellular crude polysaccharide of Isochrysis globosa produced in step (2) of Example 1, dissolve it in 100 mL of distilled water, load it on DEAE-52 ion exchange column chromatography, and first elute with distilled water, Collect 3 mL of the tube at a flow rate of 1.5 mL / min, and detect polysaccharides by the sulfuric acid-anthrone method until no polysaccharide components are detected. The polysaccharide fractions were collected together and concentrated under reduced pressure to 10 mL to obtain the neutral polysaccharide fraction (ECPSⅠ). Subsequently, the elution was continued with 1.0 mol / L NaOH, and 3 mL was collected in each tube at a flow rate of 1.5 mL / min. Polysaccharides were detected by the sulfuric acid-anthrone method until no polysaccharide components were detected. The polysaccharide fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com