Preparation method of nitrogen and phosphorus fire retardant, nitrogen and phosphorus fire retardant and application thereof

A technology of nitrogen-phosphorus flame retardants and flame retardants, which is applied in the field of nitrogen-phosphorus flame retardants and their preparation, can solve the problems of low flame retardant efficiency and decline in comprehensive mechanical properties, and achieve low cost, high char formation rate, Achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

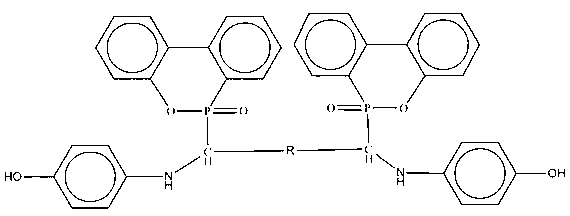

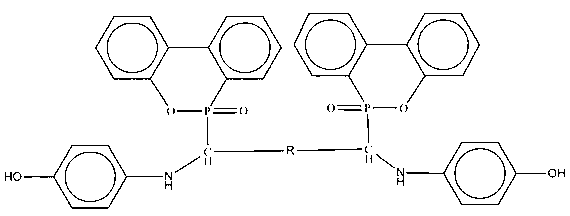

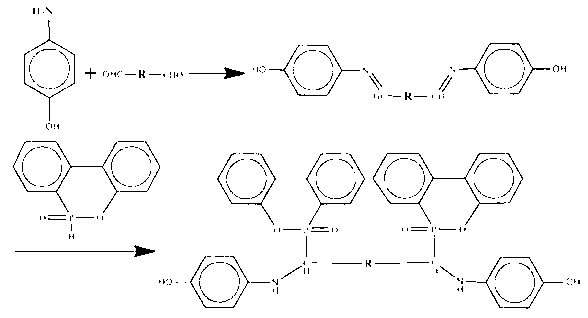

[0028] Nitrogen phosphorus flame retardant ( 1 ) The synthetic steps are as follows:

[0029] 1) Add 10.913g of 4-aminophenol, 6.707g of 1,4-benzenedicarbaldehyde and 70.480g of absolute ethanol into a three-necked flask with a stirring device, stir at a speed of 50-400 rpm, and control the reaction temperature to React at 0°C for 2-4 h. After the reaction, the reaction mixture was suction-filtered, washed, and dried in a vacuum oven at 80°C for 8 h to obtain the imine intermediate ( 1 ), the test analysis results are as follows:

[0030] FTIR (KBr, cm -1 ): 1620 (C=N), 3421 (OH), 1596, 1498, 1445, 1355, 1244, 1193, 1101, 1010, 889, 825, 767 and other characteristic peaks.

[0031] MS: m / z=315.1146 [M-H] - .

[0032] 1 H NMR (DMSO-d 6 , ppm): δ=9.56 (2OH), 8.68 (2H), 8.00 (4H), 7.26 (4H), 6.82 (4H).

[0033] 13 C NMR (DMSO-d 6 , ppm): δ=156.5, 156.2, 142.3, 138.3, 128.4, 122.6, 115.7.

[0034] 2), the above-mentioned imine intermediate product ( 1 ) 15.820 g, DOPO...

Embodiment 2

[0044] Nitrogen phosphorus flame retardant ( 2 ) The synthetic steps are as follows:

[0045] 1) Add 10.913 g of 4-aminophenol, 10.512 g of 4,4'-biphenyldicarbaldehyde and 200.0 g of absolute ethanol into a three-necked flask with a stirring device, under the action of stirring (50-400 rpm) , the reaction temperature is 60 ° C for 2-4 h, after the reaction, the reaction mixture is suction filtered, washed, and dried in a vacuum oven at 80 ° C for 8 h to obtain the imine intermediate product ( 2 ), the test analysis results are as follows:

[0046] FTIR absorption (KBr, cm -1 ): 1620 (C=N), 3430 (OH), 1593, 1505, 1446, 1367, 1251, 1103,889, 837, 781, etc.

[0047] MS: m / z=391.1447 [M-H] - .

[0048] 1 H NMR (DMSO-d 6 , ppm): δ=9.53 (2OH), 8.69 (2H), 8.01 (4H), 7.90 (4H), 7.25 (4H), 6.82 (4H).

[0049] 13 C NMR (DMSO-d 6 , ppm): δ=157.0, 156.9, 143.0, 141.8, 136.5, 129.4, 127.5, 123.1, 116.2.

[0050] 2), the above-mentioned imine intermediate product ( 2 ) 19.625g, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com