Rubber sheath material for cable

A rubber sheath and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of reduced production efficiency, narrow application fields, and many components, and achieve the effects of low cost, avoiding large pollution, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

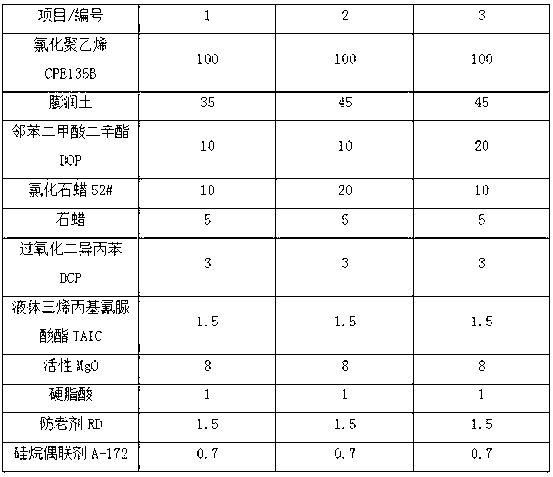

Embodiment 1

[0047] A rubber sheath material for cables, comprising the following raw material components in parts by weight:

[0048] Chlorinated polyethylene 100 parts

[0049] Bentonite 20 parts

[0050] Plasticizer 20 parts

[0051] Vulcanizing agent 2.5 parts

[0052] Vulcanizing agent 1.5 parts

[0053] Activator 1.0 parts

[0054] Anti-aging agent 0.2 parts

[0055] 0.5 parts of coupling agent

[0056] Described vulcanizing agent is organic peroxide;

[0057] Described co-curing agent is triallyl cyanurate or triacryl cyanurate;

[0058] The activator is active magnesium oxide and stearic acid mixed in a weight ratio of 8:1.

Embodiment 2

[0060] A rubber sheath material for cables, comprising the following raw material components in parts by weight:

[0061] Chlorinated polyethylene 100 parts

[0062] Bentonite 80 parts

[0063] 40 parts plasticizer

[0064] Vulcanizing agent 5.0 parts

[0065] Vulcanizing agent 6.0 parts

[0066] Activator 10 parts

[0067] Anti-aging agent 3.0 parts

[0068] 1.5 parts of coupling agent

[0069] Described vulcanizing agent is organic peroxide;

[0070] Described co-curing agent is triallyl cyanurate or triacryl cyanurate;

[0071] The activator is active magnesium oxide and stearic acid mixed in a weight ratio of 10:1.5.

Embodiment 3

[0073] A rubber sheath material for cables, comprising the following raw material components in parts by weight:

[0074] Chlorinated polyethylene 100 parts

[0075] Bentonite 50 parts

[0076] 30 parts plasticizer

[0077] Vulcanizing agent 3.75 parts

[0078] Vulcanizing agent 3.75 parts

[0079] Activator 5.5 parts

[0080] Anti-aging agent 1.6 parts

[0081] Coupling agent 1.0 parts

[0082] Described vulcanizing agent is organic peroxide;

[0083] Described co-curing agent is triallyl cyanurate or triacryl cyanurate;

[0084] The activator is active magnesium oxide and stearic acid mixed in a weight ratio of 9:1.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com