Technique for reducing viscosity of illite containing kaolin

A process method and kaolin technology, applied in the treatment of dyeing low molecular weight organic compounds, dyeing high molecular organic compounds, fibrous fillers, etc., can solve the problems of limited viscosity reduction, limited level of mechanical viscosity reduction, no technical process, etc. Achieve significant viscosity reduction, improved viscosity characteristics, and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

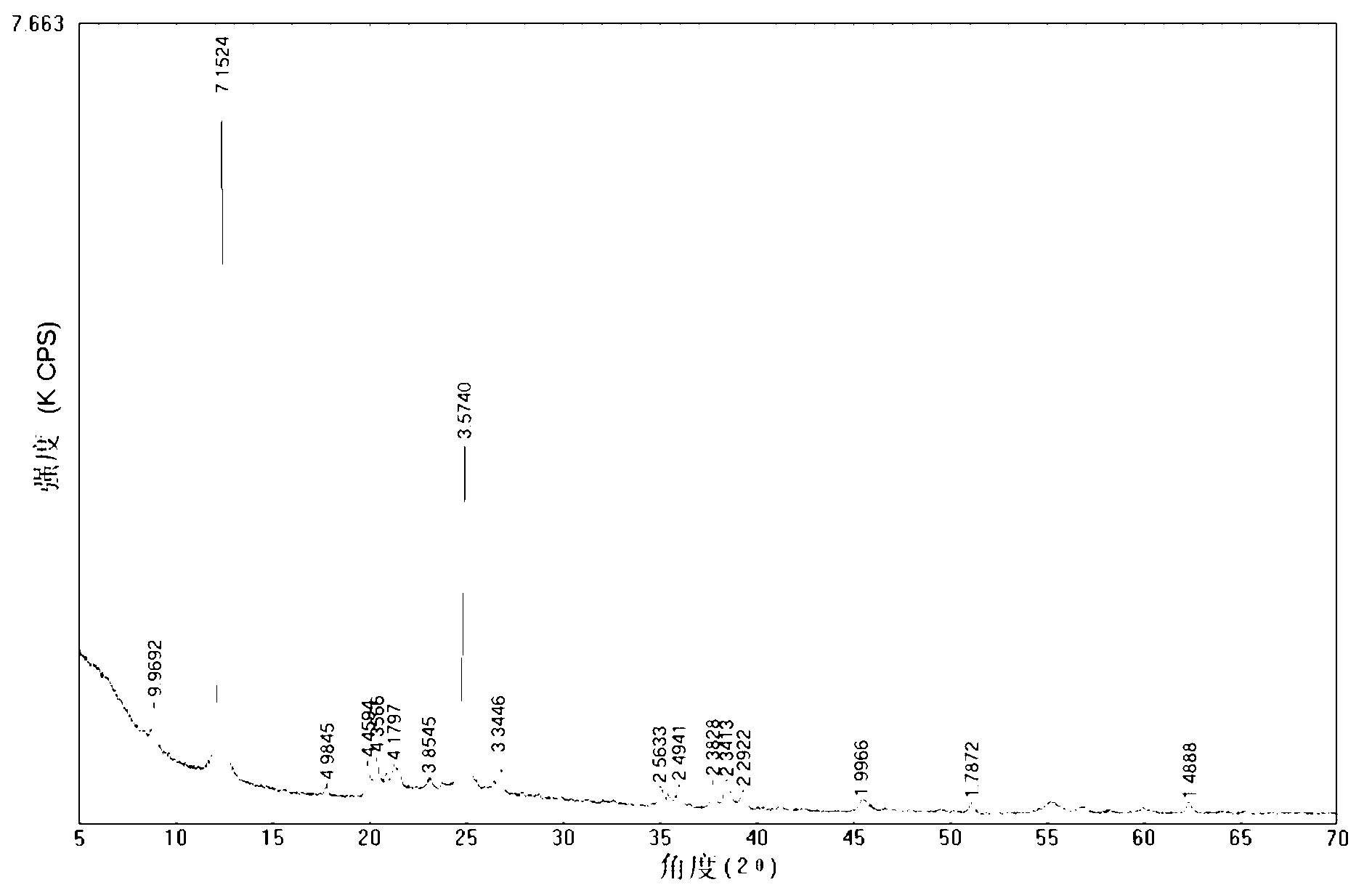

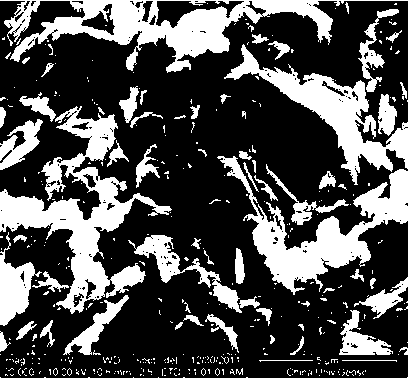

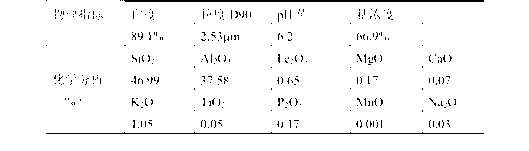

[0036] A process for reducing the viscosity of illite-containing kaolin, comprising the following steps:

[0037] (1) Purify raw kaolin ore;

[0038] (2) Take 100g of purified kaolin and 5mL of 15mg / L nitrogen methylpyrrolidone (NMF), mix them in a high-speed mixer for 5min, and then dry them in an oven at 80°C for 2h to obtain a premix;

[0039] (3) Mix 100g of the premix obtained in step (2) with 2.0g of urea in a high-speed mixer for 10 minutes, then move it into an oven, set the temperature at 90°C, keep it sealed for 2 hours, and obtain the mixture;

[0040] (4) Disperse the mixture obtained in step (3) in a high-speed mixer, add 0.35 g of composite dispersant at the same time, and mix for 10 minutes to obtain low-viscosity kaolin.

[0041] According to the national standard "GB / T 14564-2008", the viscosity concentration test is carried out. After the above treatment, the viscosity concentration of the kaolin sample can be increased from 66.9% to 71.05%.

Embodiment 2

[0043] A process for reducing the viscosity of illite-containing kaolin, comprising the following steps:

[0044] (1) Purify raw kaolin ore;

[0045] (2) Take 100g of purified kaolin and 7mL of 15mg / L nitrogen methylpyrrolidone (NMF), mix them in a high-speed mixer for 10min, and then dry them in an oven at 85°C for 2h to obtain a premix;

[0046] (3) Mix 100 g of the premix obtained in step (2) with 4.5 g of urea in a high-speed mixer for 10 minutes, then move it into an oven, set the temperature at 90°C, keep it sealed for 3 hours, and obtain the mixture;

[0047] (4) Disperse the mixture obtained in step (3) in a high-speed mixer, add 0.35 g of composite dispersant at the same time, and mix for 10 minutes to obtain low-viscosity kaolin.

[0048] According to the national standard "GB / T 14564-2008", the viscosity concentration test is carried out. After the above treatment, the viscosity concentration of the kaolin sample can be increased from 66.9% to 71.24%.

Embodiment 3

[0050] A process for reducing the viscosity of illite-containing kaolin, comprising the following steps:

[0051] (1) Purify raw kaolin ore;

[0052] (2) Take 100g of purified kaolin and 10mL of 15mg / L nitrogen methylpyrrolidone (NMF), mix them in a high-speed mixer for 8 minutes, and then dry them in an oven at 90°C for 2 hours to obtain a premix;

[0053] (3) Mix 100 g of the premix obtained in step (2) with 3.0 g of urea in a high-speed mixer for 15 minutes, then move it into an oven, set the temperature at 95°C, keep it sealed for 4 hours, and obtain the mixture;

[0054] (4) Disperse the mixture obtained in step (3) in a high-speed mixer, add 0.30 g of composite dispersant at the same time, and mix for 10 minutes to obtain low-viscosity kaolin.

[0055] According to the national standard "GB / T 14564-2008", the viscosity concentration test is carried out. After the above treatment, the viscosity concentration of the kaolin sample can be increased from 66.9% to 71.11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com