Circulation fluidized bed boiler having compact type external dual fluidized bed heat exchanger

A technology of circulating fluidized bed and double fluidized bed, applied in the field of circulating fluidized bed, can solve the problems of high processing precision requirements of ash control valve, strict layout space of heat exchange chamber, dependence on imports, etc., and simplify furnace structure and maintenance. , Solve the problem of bed temperature and steam temperature stability, improve the effect of heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

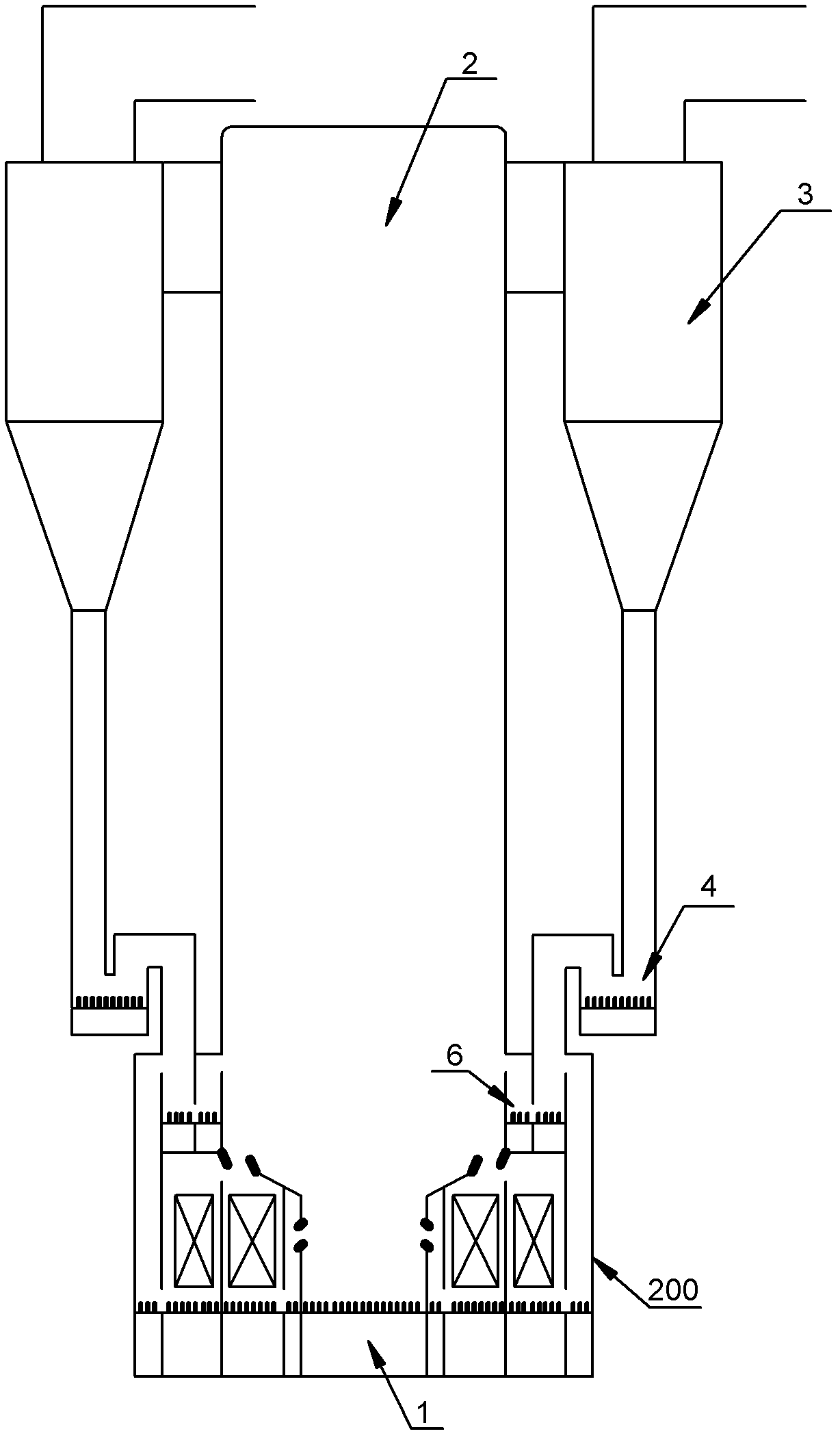

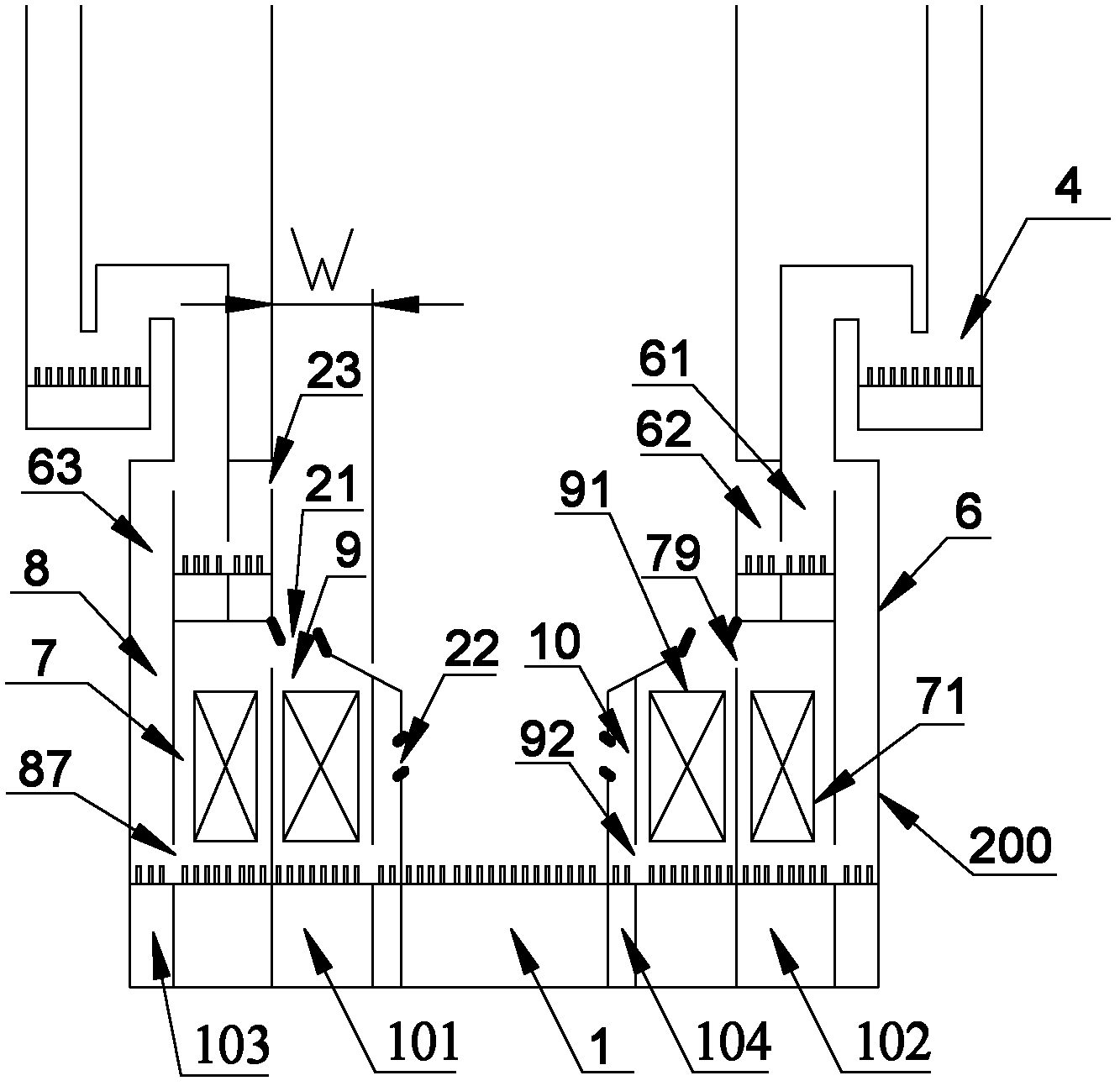

[0040] refer to Figure 1 to Figure 4 , the circulating fluidized bed boiler with compact external double fluidized bed heat exchangers provided by the present invention includes an air chamber 1, a furnace 2, a cyclone separator 3 connected to the flue gas outlet on the upper part of the furnace, and a conveying cyclone separator 3. A feeder 4 for the separated solid material, a material splitter 6 connected to the feeder 4 , an external double fluidized bed heat exchanger 200 connected to the material splitter 6 and the bottom of the furnace 2 . The tail flue communicates with the gas outlet of the cyclone separator 3, which is not shown in the figure.

[0041] The material distribution device 6 is composed of a feed channel 61 and a return channel 62, 63. The return channel 62 communicates with the furnace 2 through the overflow port 23, and the return channel 63 communicates with the solid particle outer circulation channel 8, and the outer circulation is fluidized. The b...

Embodiment 2

[0044] refer to Figure 5 , the circulating fluidized bed boiler with compact external double fluidized bed heat exchanger provided by the present invention, its bottom structure includes the material splitting device 6 for conveying the solid material separated by the cyclone separator 3, and the material splitting device 6 respectively And the external fluidized bed heat exchanger 200 connected to the bottom of the furnace 2. The material splitting device 6 is composed of a feed channel 61 and a return channel 62, 63, the return channel 62 communicates with the inner circulating fluidized bed heat exchange chamber 9, and the return material channel 63 communicates with the outer circulating fluidized bed heat exchange chamber 7, The outer circulation channel 8' communicates with the outer circulating fluidized bed heat exchange chamber 7 through the bottom through hole 78', and communicates with the inner circulating fluidized bed heat exchange chamber 9 through the upper th...

Embodiment 3

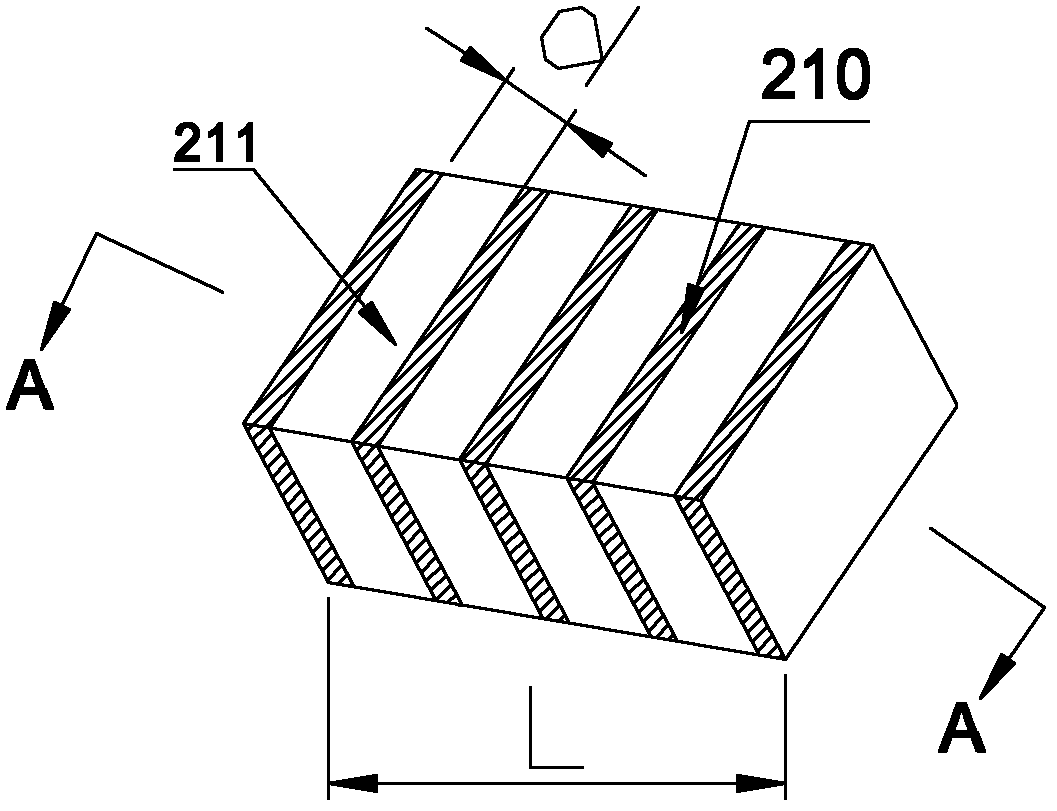

[0047] refer to Image 6 and Figure 7 , the circulating fluidized bed boiler with compact external double fluidized bed heat exchangers provided by the present invention includes an air chamber 1, a furnace 2, a cyclone separator 3 connected to the flue gas outlet on the upper part of the furnace, and a cyclone separator connected to 3 and the external double fluidized bed heat exchanger 200 at the bottom of the furnace 2, and the side wall of the downcomer of the cyclone separator 3 is arranged with a side air pipe 6' and a bypass channel 11. The outer circulating fluidized bed heat exchange chamber 7 communicates with the outer circulating channel 8 through the bottom through hole 87, and communicates with the inner circulating fluidized bed heat exchange chamber 9 through the upper through hole 79, and the inner circulating fluidized bed heat exchange chamber 9 communicates with the upper conduction channel The long and narrow groove 211 in the flow vane type feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com