Fume dried lignite medium speed mill powder-making system

A flue gas and lignite technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of poor coal combustion performance, low pulverization efficiency, insufficient boiler output, etc., to improve combustion performance and reduce Coal consumption in power generation and the effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

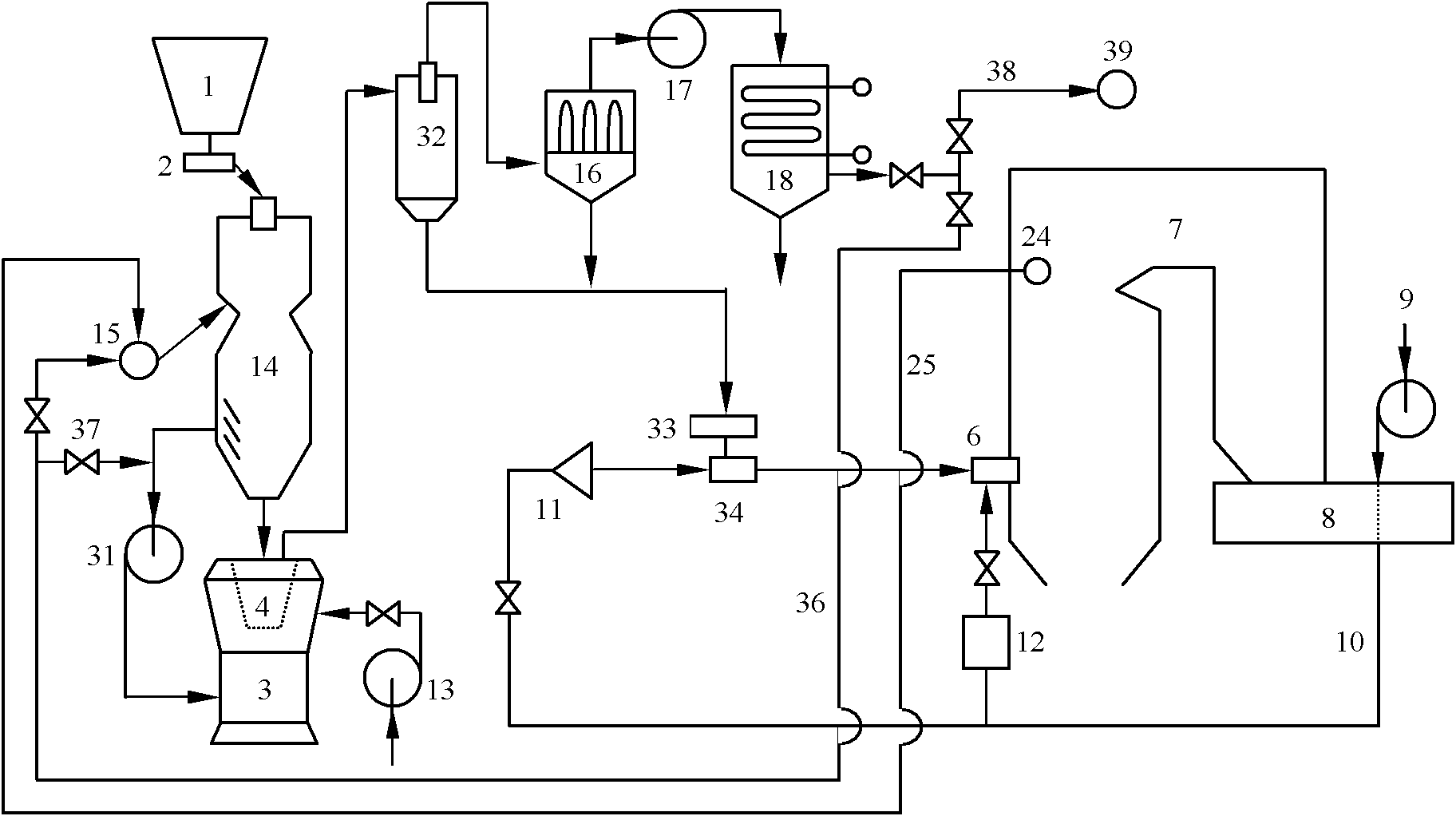

[0024] like figure 2 As shown, the flue gas drying lignite medium-speed grinding semi-direct blown pulverization system of the present invention includes a raw coal bunker 1, a coal feeder 2, a medium-speed coal mill 3, an air preheater 8, a blower 9, and a primary air box 11 , secondary air box 12, sealing fan 13, drying device 14, flue gas mixing chamber 15, bag filter 16, exhaust air fan 17, exhaust air cooler 18, powder exhaust fan 31, fine powder separator 32, powder feeder 33. Air powder mixer 34. The upper part of the medium-speed coal mill 3 has a coarse powder separator 4 .

[0025] Among them, the drying device 14 is a downward drying pipe, with a coal inlet and a high-temperature flue gas desiccant inlet at the top, a coal outlet at the bottom, and an exhaust port at the side of the bottom. The coal outlet at the bottom of the raw coal bunker 1 is connected to the coal feeder 2, and the coal feeder 2 is connected to the coal inlet at the top of the drying device ...

Embodiment 2

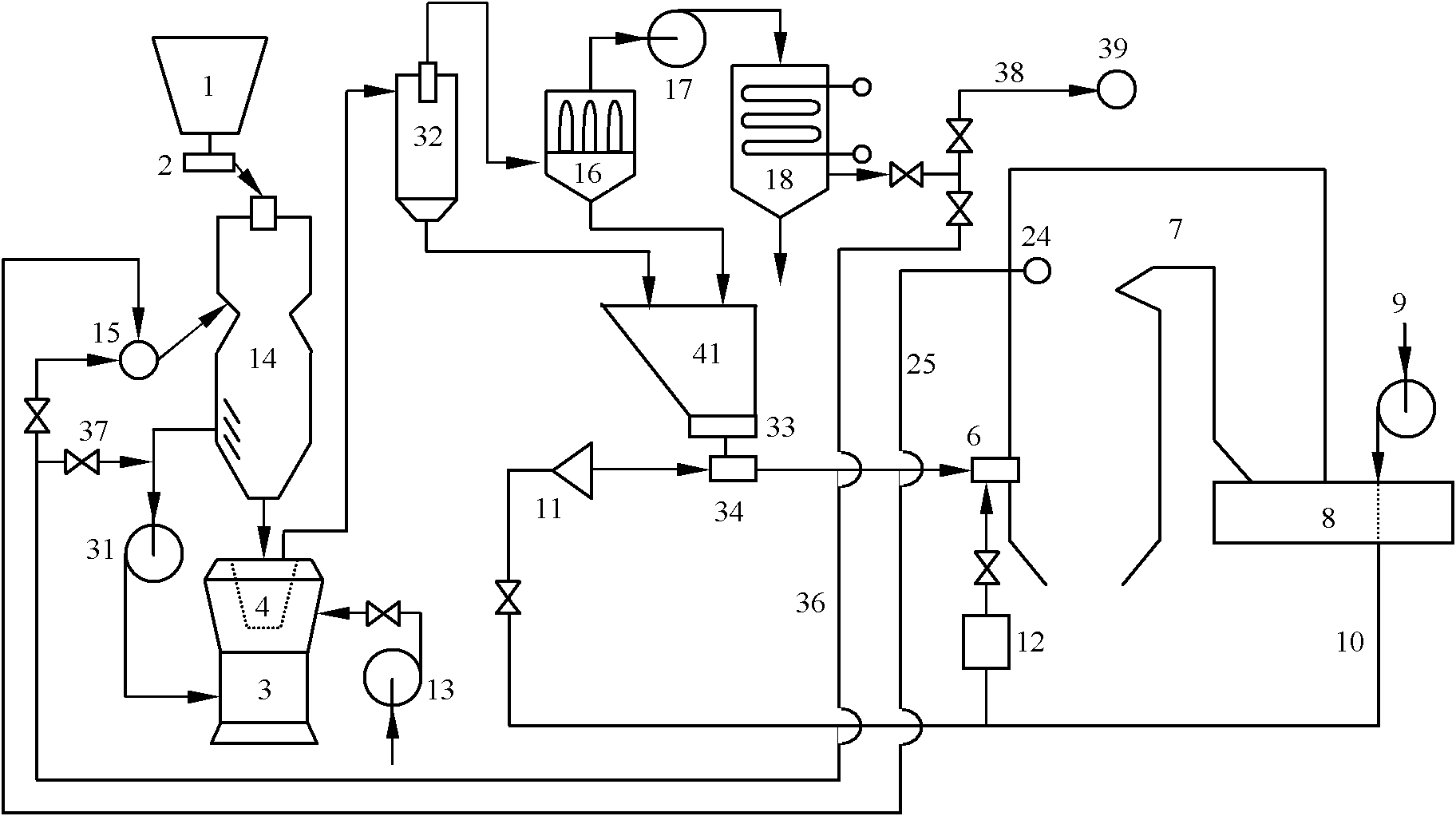

[0042] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that: a pulverized coal bin 41 is connected before the powder feeder 33, and the powder outlet of the fine powder separator 32 and the powder outlet of the dust collector 16 are connected to The pulverized coal bin 41. The pulverized coal bin 41 is arranged in front of the pulverizer 33, so that the operation of the pulverizing system will not be affected by the load of the boiler, and the stable and efficient operation of the pulverizing system can be ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com