Lossless real-time detecting method and system for magnetic conductive material

A technology of magnetic conductive material and real-time detection, applied in the direction of material magnetic variables, etc., can solve the problems of high cost of ultrasonic detection, small coupling space, unsuitable for long-term use, etc., to achieve the effect of suitable for long-term use and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

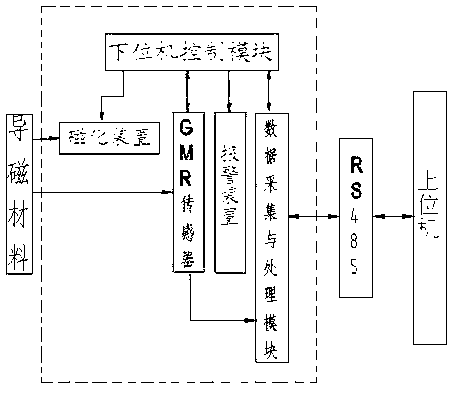

[0025] This embodiment provides a non-destructive real-time detection method for magnetically permeable materials. The system used in this method is as follows: figure 1 shown. The principle of using this method for non-destructive real-time detection of magnetically permeable materials is: when there is a defect inside the magnetically permeable material, the internal reluctance will change after it is magnetized. There are typical values of these changes in the prior art and the magnetically permeable material has no defects. The normal value in the state, the signal of the magnetized magnetic permeable material is collected by the giant magnetoresistive sensor, and these signals are further processed and compared with the above-mentioned typical value and normal value, which can display the flow of the internal magnetic field of the current position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com