Temperable glassware plated with low-radiation coating film

A low-emissivity coating and glass product technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of high cost, single performance, complex layer structure, etc., and achieve enhanced oxidation resistance , performance diversification, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

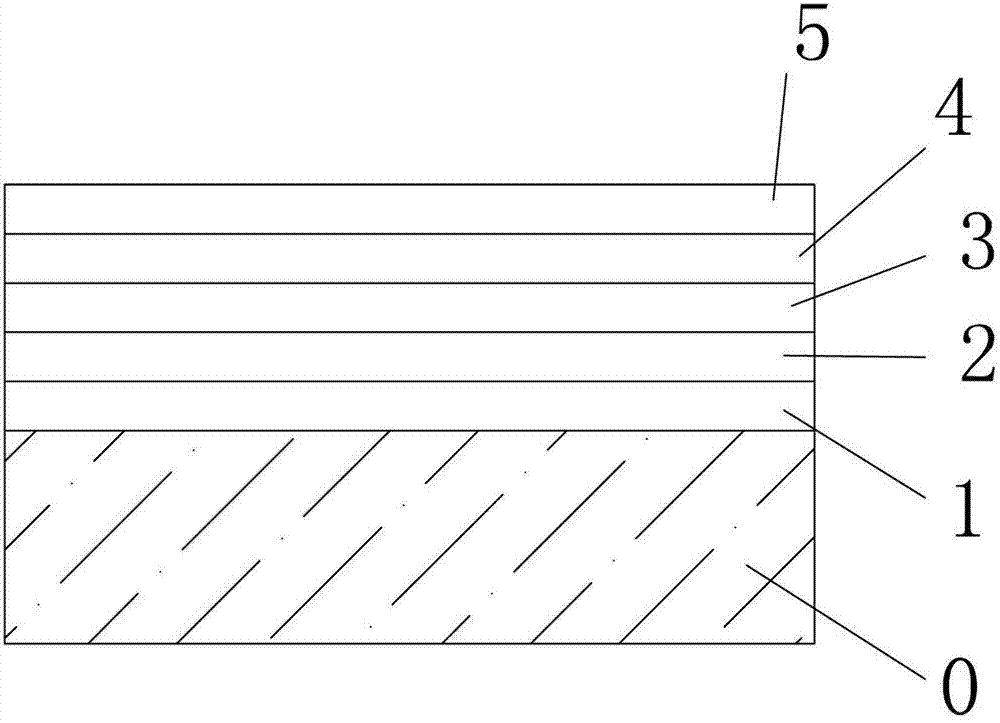

[0021] See figure 1 , a glass product that can be tempered and coated with low-emissivity coating, including glass substrate 0 layer and coating layer, the coating layer has five layers, starting from the substrate, followed by Si with a thickness of 5nm 3 N 4 Layer 1, NiCr layer 2 with a thickness of 1 nm, Ag layer 3 with a thickness of 5 nm, NiCr layer 4 with a thickness of 5 nm, and Si with a thickness of 10 nm 3 N 4 Layer 5.

[0022] The structure of glass products is: Glass / Si 3 N 4 / NiCr / Ag / NiCr / Si 3 N 4 .

[0023] After testing, the visible light transmittance is 58%, the reflection is 14%, the shading coefficient is 0.56, and the heat transfer coefficient is 3.4W / M2*K.

Embodiment 2

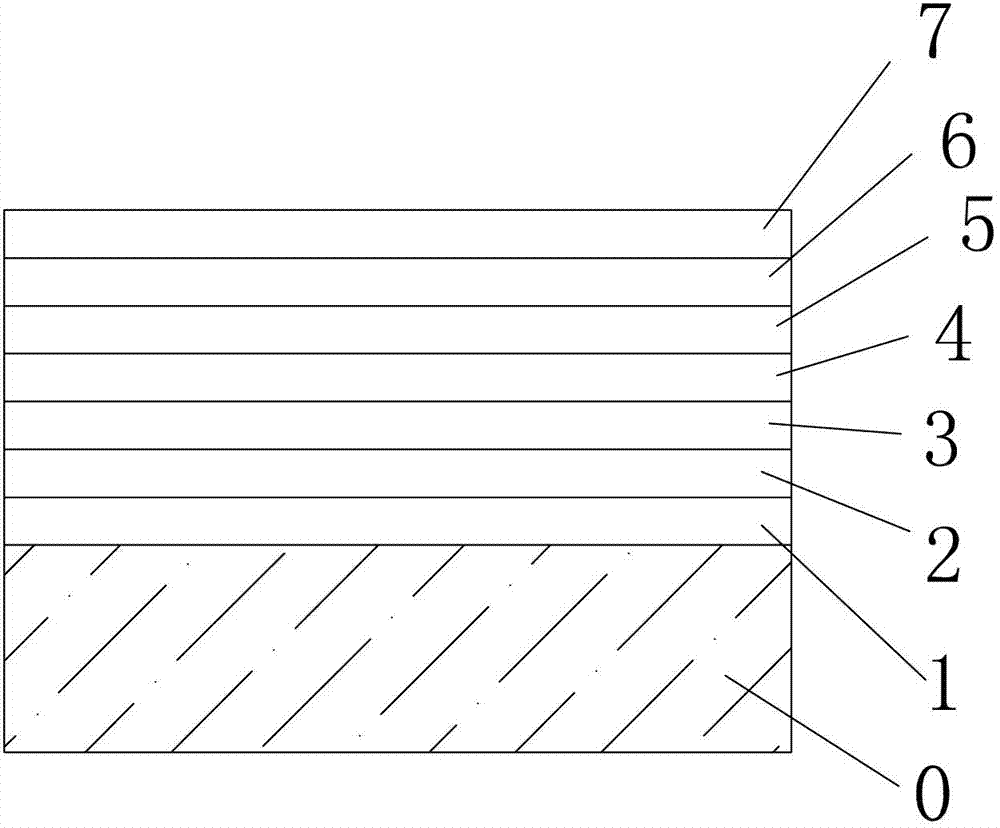

[0025] See figure 2 , a glass product that can be tempered and coated with a low-emissivity coating, including a glass substrate layer 0 and a coating layer, the coating layer has seven layers, starting from the substrate, followed by Si with a thickness of 10nm 3 N 4 Layer 1, NiCr layer 2nm thick, Si 5nm thick 3 N 4 Layer 3, NiCr layer 4 with a thickness of 10 nm, Ag layer 5 with a thickness of 20 nm, NiCr layer 6 with a thickness of 8 nm, and Si with a thickness of 5 nm 3 N 4 Layer 7.

[0026] The structure of glass products is: Glass / Si 3 N 4 / NiCr / Si 3 N 4 / NiCr / Ag / NiCr / Si 3 N 4 .

[0027] After testing, the visible light transmittance is 62%, the reflection is 10%, the shading coefficient is 0.56, and the heat transfer coefficient is 3.4W / M2*K.

Embodiment 3

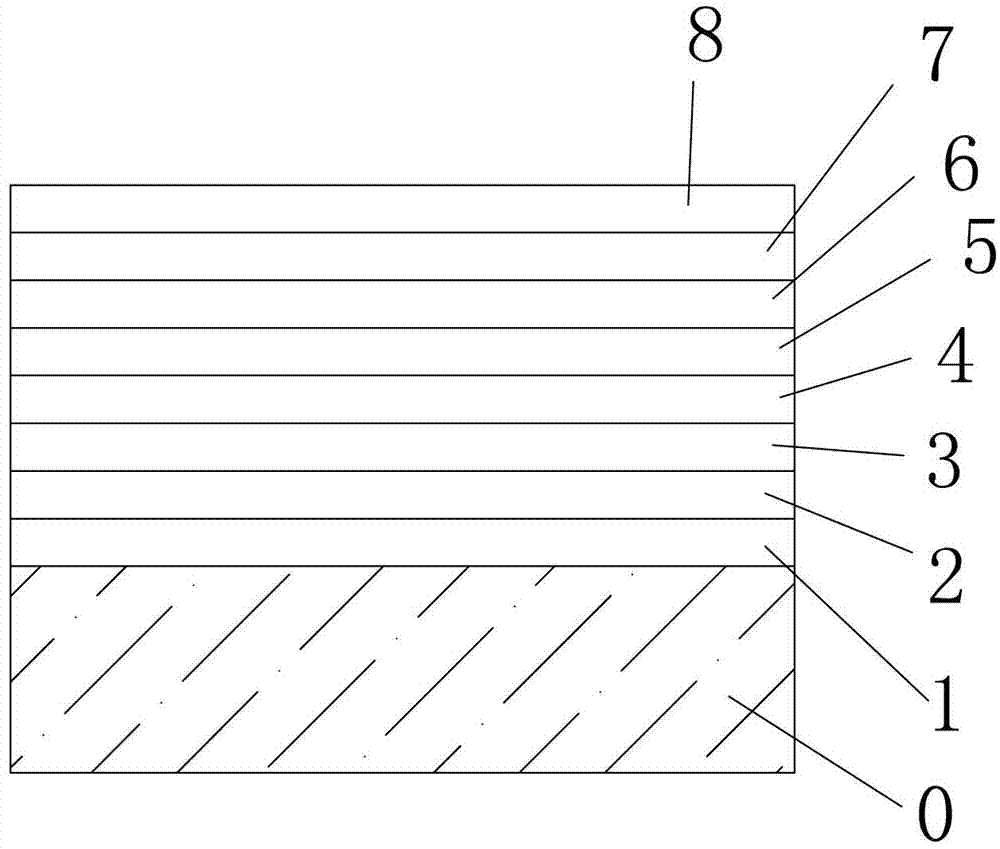

[0029] See image 3 , a glass product that can be tempered and coated with a low-emissivity coating, including a glass substrate layer 0 and a coating layer, the coating layer has eight layers, starting from the substrate, followed by Si with a thickness of 15nm 3 N 4 Layer 1, NiCr layer 2 with a thickness of 2 nm, ZnO layer 3 with a thickness of 5 nm, NiCr layer 4 with a thickness of 2 nm, Ag layer 5 with a thickness of 20 nm, NiCr layer 6 with a thickness of 4 nm, Si with a thickness of 30 nm 3 N 4 Layer 7, TiO with a thickness of 2nm 2 Layer 8.

[0030] The structure of glass products is: Glass / Si 3 N 4 / NiCr / ZnO / NiCr / Ag / NiCr / Si 3 N 4 / TiO 2 .

[0031] After testing, the visible light transmittance is 61%, the reflection is 10%, the shading coefficient is 0.57, and the heat transfer coefficient is 3.4W / M2*K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com