Luminescent glass ceramic doped with multiple rare earth ions and capable of up and down-conversion to ultraviolet light and preparation method thereof

A technology of glass ceramics and rare earth ions, applied in the field of rare earth doped glass ceramics and their preparation, to achieve the effect of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step: the CaF 2 , CaCO 3 , SiO 2 、Al 2 o 3 、H 3 BO 4 , La 2 o 3 , Y 2 o 3 , CeO 2 、Eu 2 o 3 , Tb 4 o 7 、Tm 2 o 3 、Ho 2 o 3 , Yb 2 o 3 According to the molar ratio of 8:0:68:8:0:10:0:2:0.05:2:1:0.65:0.3, it is precisely weighed and mixed evenly.

[0034] Step 2: Put the mixed raw materials in a crucible and melt them in a high-temperature furnace at a melting temperature of 1550-1600°C. After the raw materials are completely melted, they are fused, homogenized, and clarified and released at 1450-1550°C. The liquid is poured on the preheated mold; then quickly put the glass into a muffle furnace at 650°C for annealing for more than 2 hours to eliminate internal stress, then slowly cool down to below 100°C, and then turn off the power of the muffle furnace After cooling down to room temperature automatically, it was taken out to obtain a transparent glass sample.

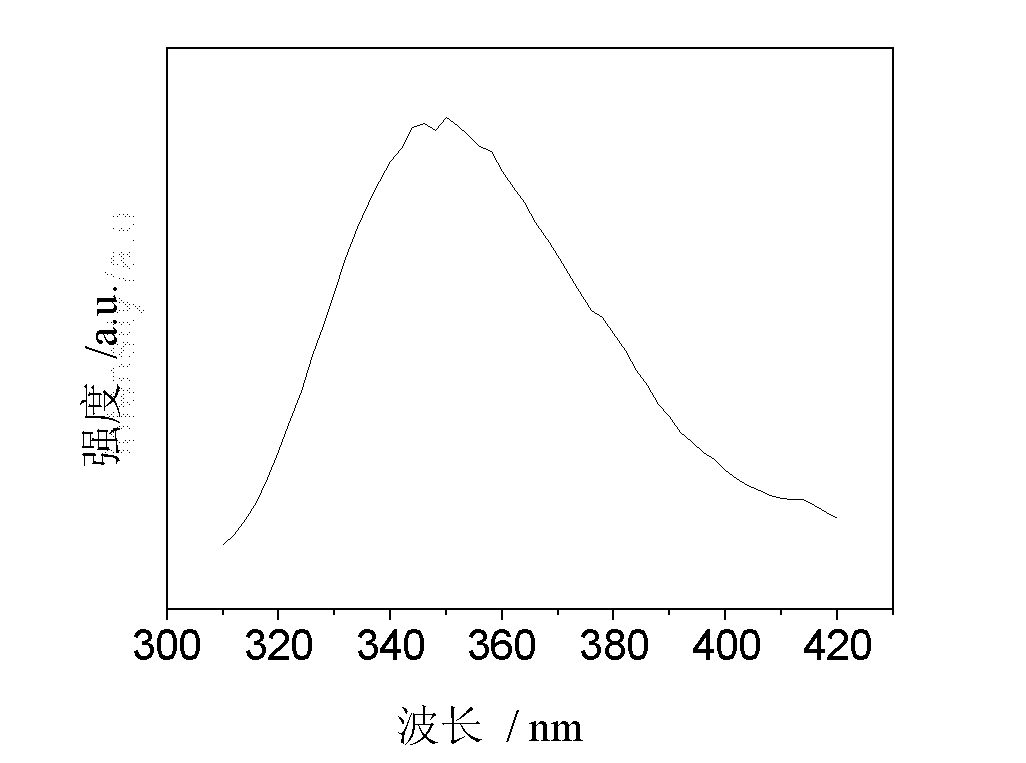

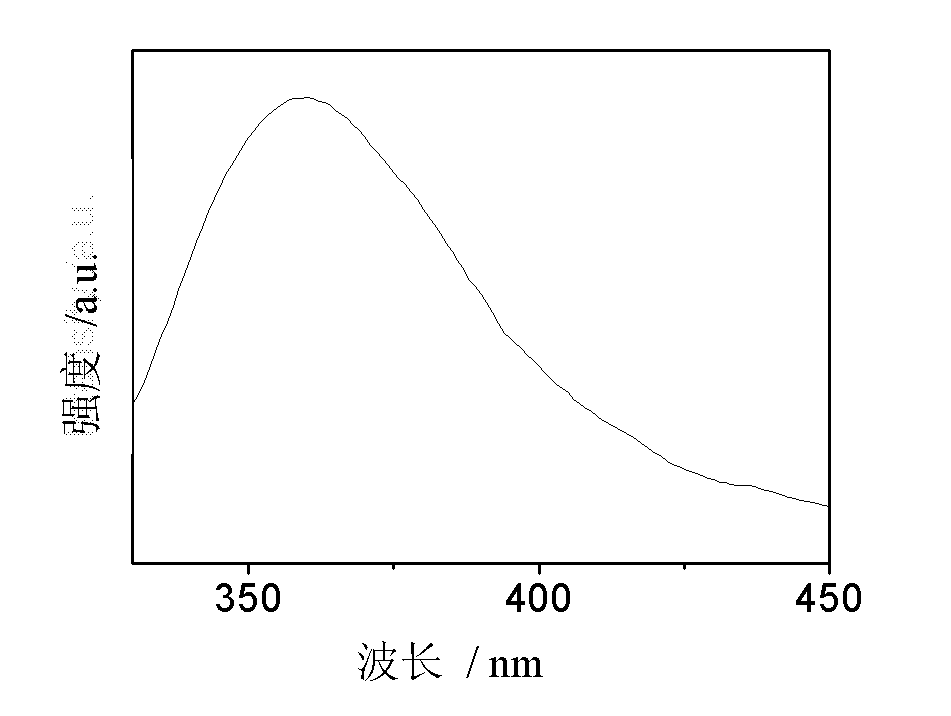

[0035] Step 3: Heat the prepared glass in a muffle furnace at 670-800°C for 0...

Embodiment 2

[0038] The first step: the CaF 2 , CaCO 3 , SiO 2 、Al 2 o 3 、H 3 BO 4 , La 2 o 3 , Y 2 o 3 , CeO 2 、Eu 2 o 3 , Tb 4 o 7 、Tm 2 o 3 、Ho 2 o 3 , Yb 2 o 3 According to the molar ratio of 15:0:62:15:0:1.5:1:3:1.5:0.00:0.75:0.1:0.15, it is precisely weighed and mixed evenly.

[0039] The second step: the melting and annealing process of the glass is basically the same as that of the first embodiment, except that the melting temperature of the glass is 1500-1600°C, and the furnace temperature is 1400-1500°C

[0040] The third step: the heat treatment process of the glass ceramics is the same as that of the first embodiment.

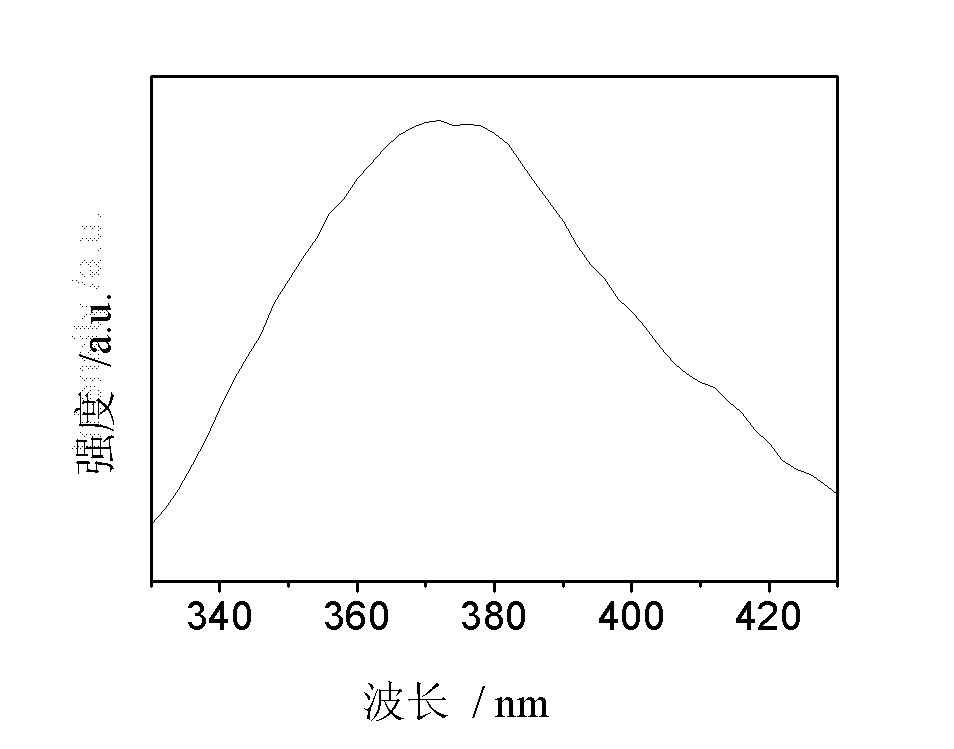

[0041] Results: The room temperature up-conversion emission spectra under 980nm and 640nm laser excitation conditions and the down-conversion emission spectra under 310nm laser excitation conditions were measured by fluorescence spectrometer, and the luminescence peak at 360-380nm was observed.

Embodiment 3

[0043] The first step: the CaF 2 , CaCO 3 , SiO 2 、Al 2 o 3 、H 3 BO 4 , La 2 o 3 , Y 2 o 3 , CeO 2 、Eu 2 o 3 , Tb 4 o 7 、Tm 2 o 3 、Ho 2 o 3 , Yb 2 o 3 According to the molar ratio of 25:0:41:17:14.9:0.32:0.31:0.16:0.1:0.05:0.06:0.1:1, it is precisely weighed and mixed evenly.

[0044] The second step: the melting and annealing process of the glass is basically the same as that of the first embodiment, except that the melting temperature of the glass is 1450-1550°C, and the furnace temperature is 1350-1450°C

[0045] The third step: the heat treatment process of the glass ceramics is the same as that of the first embodiment.

[0046] Results: The room temperature up-conversion emission spectra under 980nm and 640nm laser excitation conditions and the down-conversion emission spectra under 310nm laser excitation conditions were measured by fluorescence spectrometer, and the luminescence with a peak value of 350-375nm was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com