Novel high-efficiency PPR (pentatricopeptide repeat) pipe cold-resistant toughening color master batch

A technology of cold-resistant toughening and color masterbatch, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of inability to improve heat and cold resistance, poor dispersion effect, etc., and achieve improved flexibility and resistance Effects of impact strength, prolonging service life, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

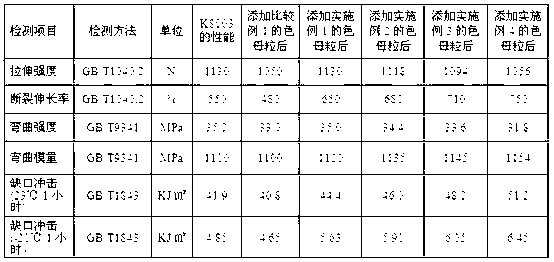

Examples

Embodiment 1

[0016] The raw material composition and parts by weight of the new high-efficiency PPR pipe material cold-resistant and toughened color masterbatch of embodiment 1 are:

[0017] 15 parts polypropylene

[0018] Pigment 50 parts

[0019] Cold resistance modifier 35 parts

[0020] Enhance modifier 1 part;

[0021] Wherein, the cold-resistant modifier is styrene-butadiene-styrene ternary block copolymer (SBS), the reinforcing modifier is nano-calcium carbonate, and the particle size of the reinforcing modifier is 10-50nm , the polypropylene is a homopolypropylene.

[0022] The preparation method of the novel high-efficiency PPR pipe cold-resistant and toughened color masterbatch of embodiment 1 comprises the following steps:

[0023] 1) Pre-dispersion treatment of pigments: Add pigments and dispersants to a high-speed mixer and mix to achieve the effect of pigment pre-dispersion. The dispersant is a mixture of coupling agent, polymer wax and stearate;

[0024] 2) Mix the pre-...

Embodiment 2

[0027] The raw material composition and parts by weight of the new high-efficiency PPR pipe material cold-resistant and toughened color masterbatch of embodiment 2 are:

[0028] 5 parts polypropylene

[0029] Pigment 35 parts

[0030] Cold resistance modifier 45 parts

[0031] Enhance modifier 3 parts;

[0032] Wherein, the cold-resistant modifier is ethylene-octene copolymer (POE), the reinforcing modifier is nano-silicon, the particle size of the reinforcing modifier is 10-50 nm, and the polypropylene is copolymerized polypropylene.

[0033] The preparation method of the novel high-efficiency PPR pipe cold-resistant and toughened color masterbatch of embodiment 2 comprises the following steps:

[0034] 1) Pre-dispersion treatment of pigments: Add pigments and dispersants to a high-speed mixer and mix to achieve the effect of pigment pre-dispersion. The dispersant is a mixture of coupling agent, polymer wax and stearate;

[0035] 2) Mix the pre-dispersed pigment with poly...

Embodiment 3

[0038] The raw material composition and parts by weight of the new high-efficiency PPR pipe material cold-resistant and toughened color masterbatch of embodiment 3 are:

[0039] 25 parts polypropylene

[0040] Pigment 20 parts

[0041] Cold resistance modifier 55 parts

[0042] Enhance modifier 8 parts;

[0043] Wherein, the cold resistance modifier is a mixture of styrene-butadiene-styrene ternary block copolymer (SBS) and ethylene-vinyl acetate copolymer (EVA), and the reinforcing modifier is nano calcium carbonate and nano barium sulfate, the particle size of the reinforcement modifier is 10-50nm, and the polypropylene is copolymerized polypropylene.

[0044] The preparation method of the novel high-efficiency PPR pipe cold-resistant and toughened color masterbatch of embodiment 3 comprises the following steps:

[0045] 1) Pre-dispersion treatment of pigments: Add pigments and dispersants to a high-speed mixer and mix to achieve the effect of pigment pre-dispersion. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com