A kind of nylon 6/polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of nylon 6/polypropylene composite material and its preparation, can solve the problem that it is difficult to ensure the uniformity of fiber dispersion, the weight stability of parts, the color stability, and the easy discoloration of nylon resin and other problems, to achieve the effect of simple structure, improved hydrolysis resistance and heat resistance, and stable weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

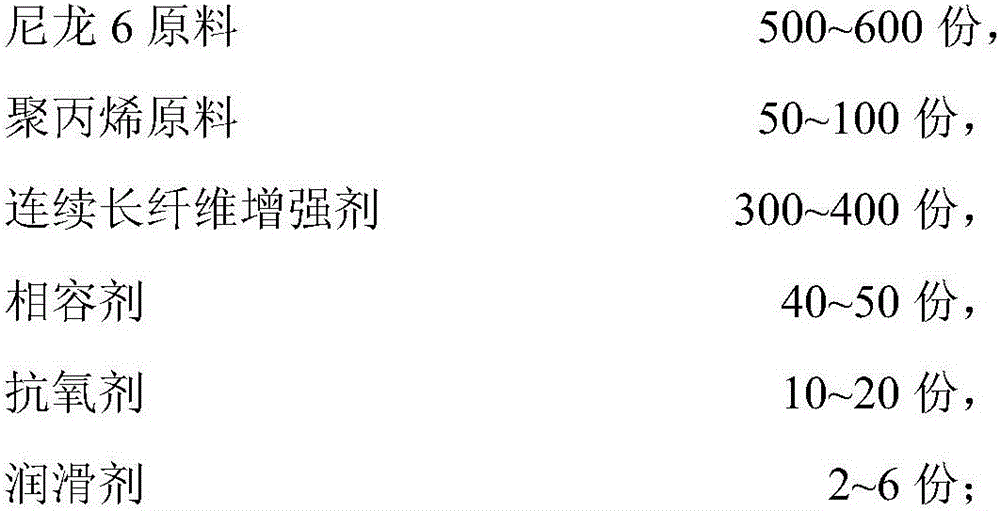

[0044] (1) Take each raw material according to the following ratios,

[0045] PA6 raw material 500 parts,

[0046] PP raw material 100 parts,

[0047] Continuous long fiber reinforcing agent 350 parts,

[0048] 50 parts of compatibilizer,

[0049] Antioxidant 12 parts,

[0050] Lubricant 5 parts.

[0051] PA6 raw material, its melt index is 10-20g / 10min (230℃, 2.16Kg);

[0052] PP is homopolypropylene with a melt index of 10-40g / 10min (230°C, 2.16Kg);

[0053] The continuous long fiber reinforcement is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0054] The compatibilizer is PP-g (maleic anhydride grafted polypropylene resin), wherein the grafting rate of maleic anhydride is 0.5-1.5%;

[0055] Antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4 hydroxyphenylpropionyl-hexamethylenediamine), and antioxidant 168 (tri-(2,4-di-tert-butylphenol phosphite) )), the weight ratio of the two is 1:2;

[0056] The lubricant is ethylene-acrylic acid copolymer;...

Embodiment 2

[0064] (1) Take each raw material according to the following ratios;

[0065] PA6 raw material 530 parts,

[0066] PP raw material 70 parts,

[0067] Continuous long fiber reinforcing agent 350 parts,

[0068] 50 parts of compatibilizer,

[0069] Antioxidant 12 parts,

[0070] Lubricant 5 parts.

[0071] Among them, the melt index of PA6 is 10-20g / 10min (230°C, 2.16Kg);

[0072] PP is homopolypropylene with a melt index of 10-40g / 10min (230°C, 2.16Kg);

[0073] The continuous long fiber reinforcement is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0074] The compatibilizer is PP-g (maleic anhydride grafted polypropylene resin), wherein the grafting rate of maleic anhydride is 0.5-1.5%;

[0075] Antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4 hydroxyphenylpropionyl-hexamethylenediamine), and antioxidant 168 (tri-(2,4-di-tert-butylphenol phosphite) )), the weight ratio of the two is 1:2;

[0076] The lubricant is ethylene-acrylic acid copolym...

Embodiment 3

[0086] (1) Take each raw material according to the following ratios;

[0087] PA6 raw material 550 parts,

[0088] 50 parts of PP raw material,

[0089] Continuous long fiber reinforcing agent 350 parts,

[0090] 50 parts of compatibilizer,

[0091] Antioxidant 12 parts,

[0092] Lubricant 5 parts.

[0093] PA6 raw material, its melt index is 10-20g / 10min (230℃, 2.16Kg);

[0094] PP is homopolypropylene with a melt index of 10-40g / 10min (230°C, 2.16Kg);

[0095] The continuous long fiber reinforcement is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0096] The compatibilizer is PP-g (maleic anhydride grafted polypropylene resin), wherein the grafting rate of maleic anhydride is 0.5-1.5%;

[0097] Antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4 hydroxyphenylpropionyl-hexamethylenediamine), and antioxidant 168 (tri-(2,4-di-tert-butylphenol phosphite) )), the weight ratio of the two is 1:2;

[0098] The lubricant is ethylene-acrylic acid copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com