Heat-seal polyvinylidene chloride emulsion used for coating, and preparation method thereof

A polyvinylidene chloride, heat-sealing technology, applied in the direction of coating, etc., can solve the problem of poor heat-sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Weigh 17 kg of vinylidene chloride, 15 kg of vinyl chloride, 18 kg of acrylic acid, 10 kg of maleic acid and 38 kg of demineralized water into a stainless steel container. Start stirring, the stirring speed is 120 rpm, and the temperature is slowly heated to 45°C. Then gradually add 0.17 kg of potassium persulfate, 0.33 kg of ammonium persulfate, and 1 kg of sodium dodecyl sulfonate. After 1 hour, the monomers are completely polymerized, the mixer is turned off, and the mixture is cooled and allowed to stand for 30 minutes. Add 0.17 kg of ethanol and 0.33 kg of octanol, start stirring again, and the stirring speed is 120 rpm. After 30 minutes, 100 kg of PVDC copolymer emulsion with a solid content of 62% is obtained.

[0028] 2. Take 95 kg of the prepared PVDC copolymer emulsion, put it into another stainless steel container, add 5 kg of EVA emulsion, start stirring, set the stirring speed to 120 rpm and the stirring time to 30 minutes, so that the two The copolymer...

Embodiment 2

[0032] 1. Weigh 20 kg of vinylidene chloride, 15 kg of vinyl chloride, 17 kg of acrylic acid, 10 kg of maleic acid and 36.3 kg of demineralized water into a stainless steel container. Start stirring, the stirring speed is 120 rpm, and the temperature is slowly heated to 48°C. Then gradually add 0.13 kg of potassium persulfate, 0.27 kg of ammonium persulfate, and 0.8 kg of sodium dodecyl sulfate. After 1 hour, the monomers are completely polymerized, turn off the mixer, and cool and stand for 30 minutes. Add 0.17 kg of ethanol and 0.33 kg of octanol, start stirring again, and the stirring speed is 120 rpm. After 30 minutes, 100 kg of PVDC copolymer emulsion with a solid content of 63.7% is obtained.

[0033] 2. Take 94 kg of the prepared PVDC copolymer emulsion, put it into another stainless steel container, add 6 kg of EVA emulsion, start stirring, set the stirring speed to 120 rpm, and set the stirring time to 30 minutes, so that the two The copolymer emulsion was thoroughly...

Embodiment 3

[0037] 1. Weigh 25 kg of vinylidene chloride, 14 kg of vinyl chloride, 16 kg of acrylic acid, 9 kg of maleic acid and 34.5 kg of demineralized water into a stainless steel container. Start stirring, the stirring speed is 120 rpm, and the temperature is slowly heated to 50 °C. Then gradually add 0.17 kg of potassium persulfate, 0.33 kg of ammonium persulfate, and 0.6 kg of OP-10. After 1 hour, the monomers are completely polymerized, turn off the mixer, cool and stand for 30 minutes. Add 0.13 kg of ethanol and 0.27 kg of octanol, start stirring again, and the stirring speed is 120 rpm. After 30 minutes, 100 kg of PVDC copolymer emulsion with a solid content of 65.5% is obtained.

[0038] 2. Take 92 kg of the prepared PVDC copolymer emulsion, put it into another stainless steel container, add 8 kg of EVA emulsion, start stirring, set the stirring speed to 120 rpm, and the stirring time to 30 minutes, so that the two The copolymer emulsion was thoroughly mixed to obtain 100 kg o...

PUM

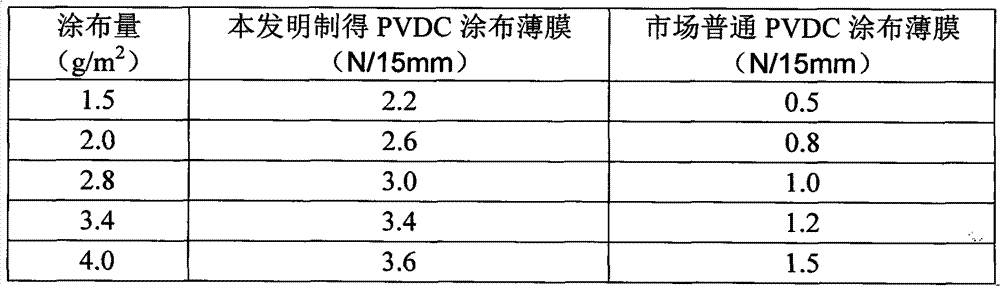

| Property | Measurement | Unit |

|---|---|---|

| Heat seal strength | aaaaa | aaaaa |

| Heat seal strength | aaaaa | aaaaa |

| Heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com