Escherichia coli engineering strain having high phenethyl alcohol yield and application thereof

An engineering strain, Escherichia coli technology, applied in the field of metabolic engineering, can solve the problem of low synthesis or transformation ability, and achieve the effect of promoting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Construction and identification of embodiment 1 recombinant plasmid

[0052] The genomes of Pichia pastoris GS115 and Saccharomyces cerevisiae S288c were used as templates to obtain kdc and adh1 respectively,

[0053] The primers are as follows (the framed part is RBS, the underlined part is the primer restriction site)

[0054] kdc F:TCC CCCGGG ATGGCCCCAGTTCCAGATATAGCA

[0055] R:C GAGCTC TTAACCTACGATTTTGGCTTTGTTCTTG

[0056] adh1 F:AAAA CTGCAGGTAA ATGTCTATCCCCAGAAACTCAAAAAAGGTGT

[0057] R::CGC GGATCC GAATTTTCGTTTTAAAACCTAAGAGTCACTTTA

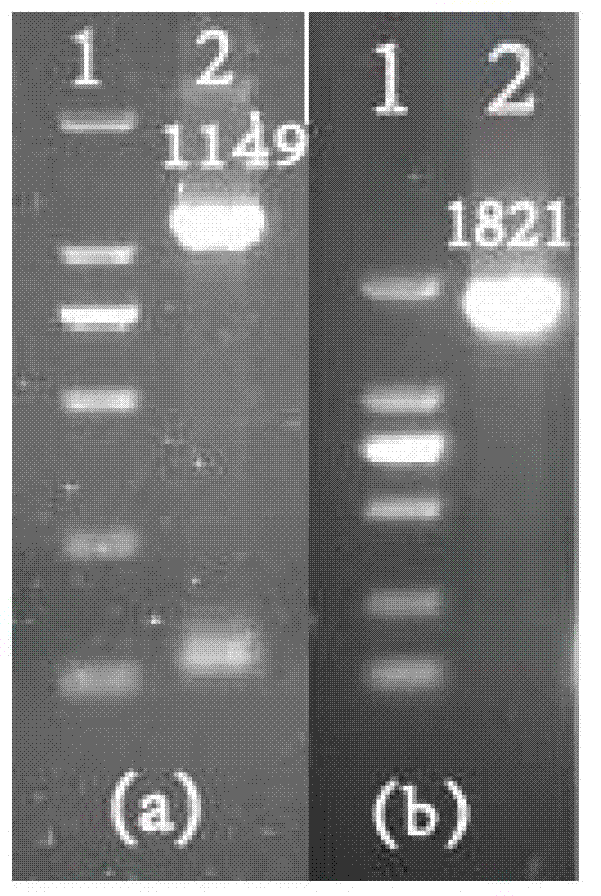

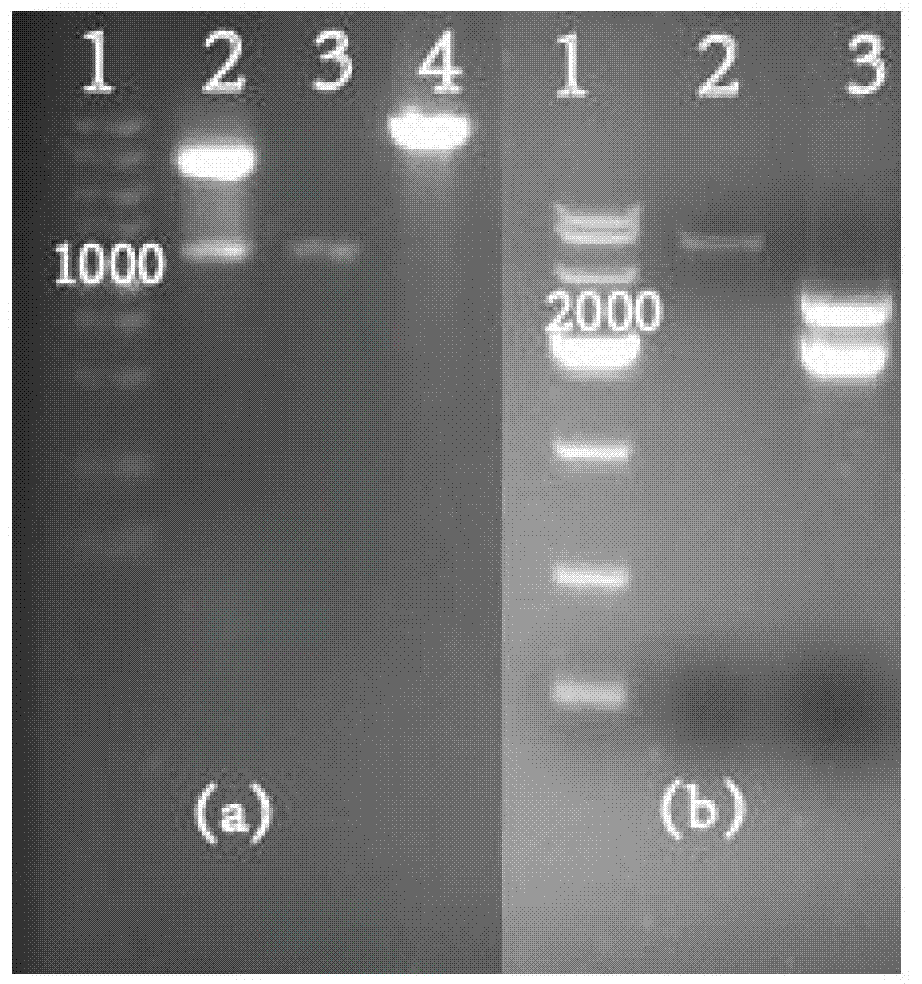

[0058] The reaction conditions are: 94°C for 5min; then 94°C for 30s, 62°C(adh1) / 63°C(kdc) for 30s, 72°C for 70s(adh1) / 108s(kdc) (30 cycles); 72°C for 10min for PCR The reaction was verified by 0.8% agarose gel electrophoresis and the PCR amplification product was recovered. As a result, the adh1 / kdc gene fragment ( figure 1 (a) - lane 2, figure 1 (b) - lane 2). The adh1 / kdc gene digested and purified with restrictio...

Embodiment 2

[0059] Example 2 The effect of co-expressing ADH1 and KDC enzymes on recombinant Escherichia coli phenylethanol fermentation

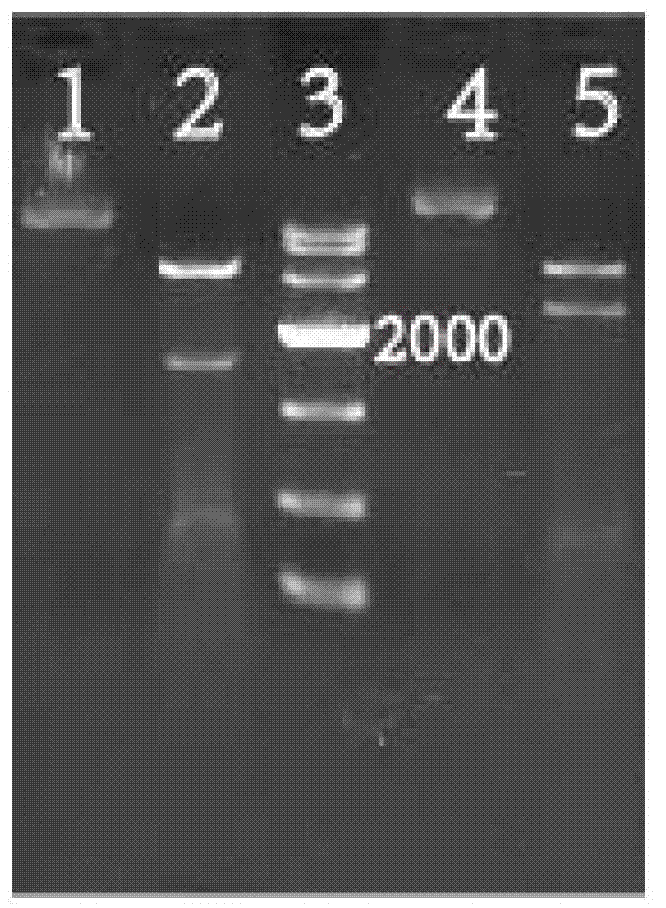

[0060] Different recombinant bacteria Escherichia coli were compared with the starting bacteria for fermentation experiments. Recombinant bacteria E.coli pAP-B03 / pCL-adh1-kdc were used for fermentation experiments, and the production of phenylalanine and β-phenylethanol was determined as follows: Figure 4 Shown: β-phenylethanol can be produced by both single and co-expression of phenylpyruvate decarboxylase (KDC) and alcohol dehydrogenase (ADH1), and the expression of β-phenylethanol under the condition of simultaneous expression of two enzyme genes The yield is the highest, the highest can reach 130mg / L, and the yield of phenylethyl alcohol cannot be detected by the starting bacteria E.coli pAP-B03 ( Figure 4 ).

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com