Novel titanium alloy partitioned beta heat treatment process

A titanium alloy and process technology, which is applied in the field of titanium alloy partition β heat treatment process, to achieve the effect of ensuring uniform structure, good comprehensive performance and low fatigue crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

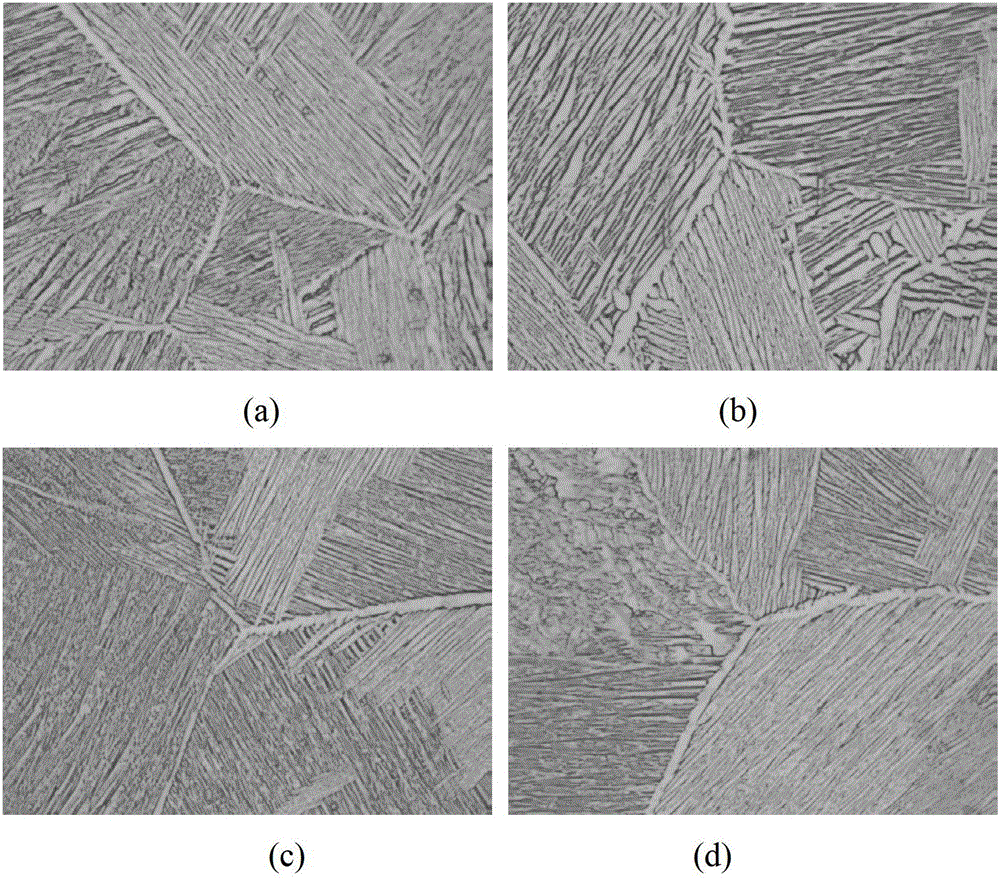

[0026] TC4-DT titanium alloy is a large complex variable cross-section free forging after forging in the α + β zone (the maximum size of the outer shape is 2400 (L) mm × 590 mm (T) × 260 mm (ST), the maximum thickness is 260 mm, and the minimum thickness is 100 mm. The weight of the forging is up to 800kg). After adopting the above-mentioned divisional β heat treatment process, it is then kept at 730°C for 4 hours and air-cooled. The results of chemical anatomy analysis show that the microstructure uniformity of different parts of the forging is good ( figure 1 ), the uniformity of mechanical properties is good (Table 2 and Table 3), and the strength-plasticity-toughness matching is good.

[0027] Table 1 Tensile properties of different parts of free forgings

[0028]

[0029]

[0030] Table 2 Fracture toughness of different parts of free forgings

[0031]

Embodiment 2

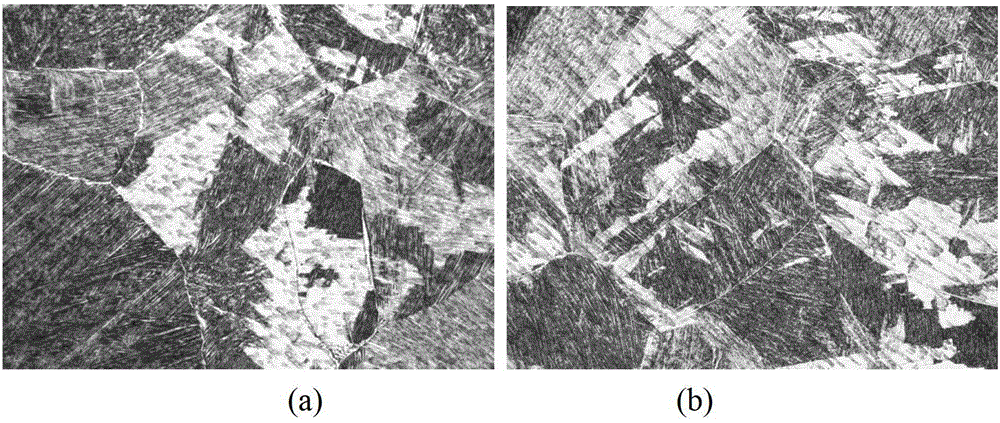

[0033] TC4-DT titanium alloy is a large and complex variable cross-section die forging after forging in the α+β zone (the maximum size of the outer shape is 1720mm×1120mm×217mm, the maximum thickness is 217mm, the minimum thickness is 113mm, and the weight of a single piece is nearly 500Kg), using the above-mentioned partition β After the heat treatment process, the microstructure after being kept at 730°C for 4 hours and air-cooled is as follows: figure 2 As shown, it can be seen that the organization is a lamellar organization with good uniformity. The mechanical properties are shown in Table 3 and Table 4. Good strength-plasticity-toughness matching and low da / dN values can be obtained after zoned β heat treatment.

[0034] Table 3 Tensile properties of different parts of die forgings

[0035]

[0036]

[0037] Table 4 Fracture toughness and crack growth rate of different parts of die forgings

[0038]

Embodiment 3

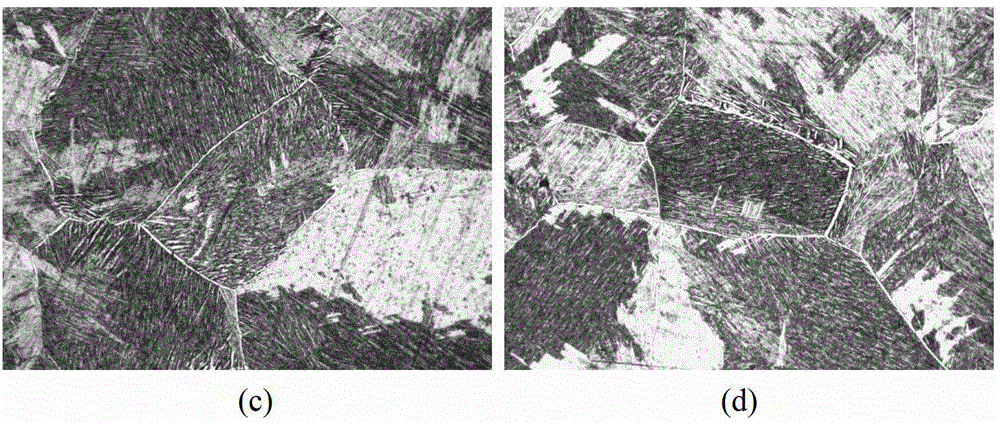

[0040] TC4-DT titanium alloy is a large and complex variable cross-section die forging after forging in the α+β zone (the maximum size of the outer profile is 1900mm×1375mm×160mm, the maximum thickness is 160mm, the minimum thickness is 130mm, and the weight of a single piece is nearly 500Kg), using the above-mentioned partition β After the heat treatment process, the microstructure after being kept at 730°C for 4 hours and air-cooled is as follows: image 3 As shown, it can be seen that the organization is a uniform lamellar organization. The mechanical properties are shown in Table 5 and Table 6. It can be seen from the table that the tensile properties and fracture toughness are higher than the standard requirements, and a good strength-plasticity-fracture toughness matching is obtained.

[0041] Table 5 Tensile properties of different parts of die forgings

[0042]

[0043] Table 6 Fracture toughness of die forgings

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com