Heater for MOCVD (metal-organic chemical vapor deposition) equipment

A heater and equipment technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low heating precision control, poor temperature field uniformity, easy oxidation and deformation, and achieve automatic and reasonable control temperature mode, meet the strict requirements, and ensure the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in detail below with reference to the drawings and embodiments.

[0019] In view of the heating temperature requirements of the MOCVD equipment, the present invention mainly designs the heater from three aspects: the selection of the heating furnace body material, the design of the heating body structure, and the design of the heating temperature controller.

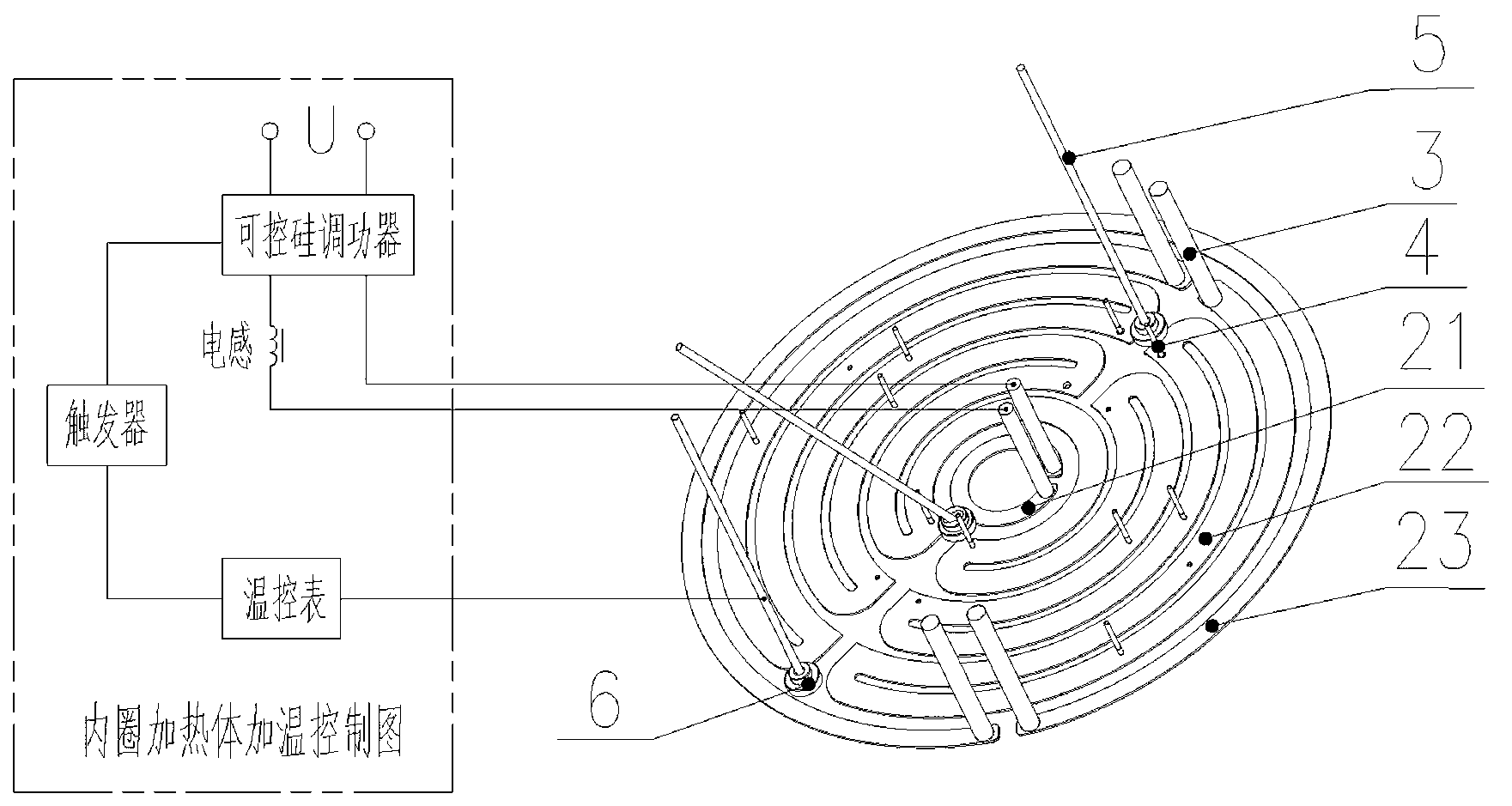

[0020] Such as figure 1 As shown, the heater for MOCVD equipment proposed by the present invention includes a disc-shaped furnace body, wherein the furnace body is divided into three areas: an inner ring, a middle ring, and an outer ring. These three areas are respectively provided with an inner ring heater 21 , Middle ring heating body 22 and outer ring heating body 23, each group of heating bodies is controlled by a separate heating power controller.

[0021] Such as figure 1 As shown, the inner ring heating body 21, the middle ring heating body 22 and the outer ring heating body 23 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com