Antibacterial undergarment fabric

A technology of underwear fabric and compound antibacterial agent, applied in textile and papermaking, fiber treatment, plant fiber and other directions, can solve the problems of weakened antibacterial effect and poor durability of antibacterial underwear fabric, and achieve excellent antibacterial effect, good health care function, affinity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

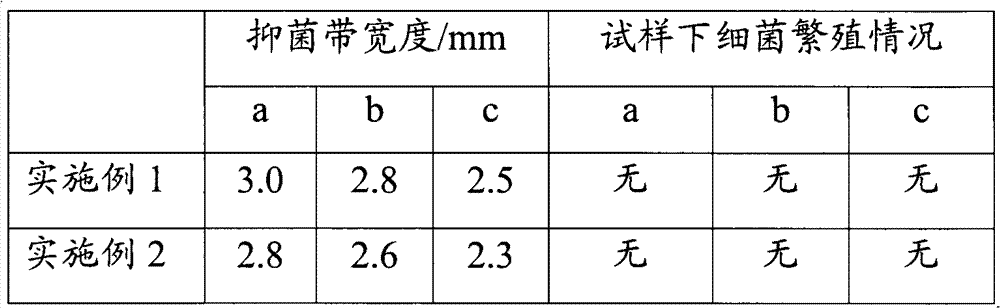

Examples

Embodiment 1

[0021] Preparation of composite antibacterial agent:

[0022] 60 parts of nano titanium dioxide;

[0023] 3 parts of dodecylguanidine;

[0024] 5 parts of 2,4,4'-trichloro-2'-hydroxyl diphenyl ether;

[0025] 0.5 part of sodium polyacrylate dispersant;

[0026] 1 part of silane coupling agent.

[0027] Specifically, mix dodecylguanidine, 2,4,4'-trichloro-2'-hydroxydiphenyl ether and sodium polyacrylate dispersant, then slowly add titanium dioxide and silane coupling agent at the same time, and feed within 30 minutes When complete, continue mixing for 30 minutes. After mixing the components, water is added to form a compound antibacterial agent with a mass concentration of 40%.

[0028] Preparation of antibacterial underwear fabric:

[0029] The underwear fabric that is blended with 55% cotton fiber, 30% soybean protein fiber, and 15% bamboo fiber by mass percentage is immersed in the dipping solution containing the above-mentioned composite antibacterial agent for 30 min...

Embodiment 2

[0031] Preparation of composite antibacterial agent:

[0032] 65 parts of nano titanium dioxide;

[0033] 1 part of dodecylguanidine;

[0034] 3 parts of 2,4,4'-trichloro-2'-hydroxyl diphenyl ether;

[0035] 1 part of sodium polyacrylate dispersant;

[0036] 0.5 part of silane coupling agent.

[0037] Specifically, mix dodecylguanidine, 2,4,4'-trichloro-2'-hydroxydiphenyl ether and sodium polyacrylate dispersant, then slowly add titanium dioxide and silane coupling agent at the same time, and feed within 30 minutes When complete, continue mixing for 30 minutes. After the components are mixed, water is added to form a compound antibacterial agent with a mass concentration of 15%.

[0038] Preparation of antibacterial underwear fabric:

[0039] The underwear fabric that is blended with 60% cotton fiber, 20% soybean protein fiber, and 20% bamboo fiber by mass percentage is immersed in the dipping solution containing the above-mentioned composite antibacterial agent for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com