Single-component puzzle glue and preparation method thereof

A kind of panel glue, one-component technology, applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems of coagulation failure, low water resistance, environmental and human hazards of panel glue, etc. Problems, avoiding the migration of the bonding interface, high bonding strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

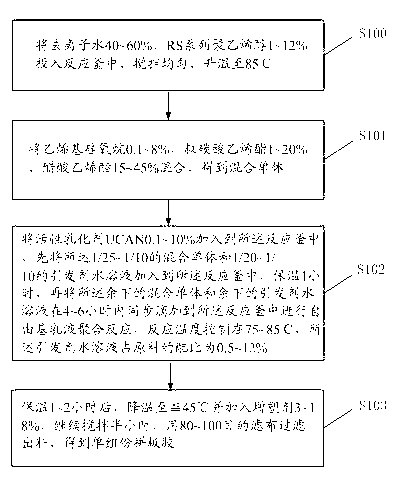

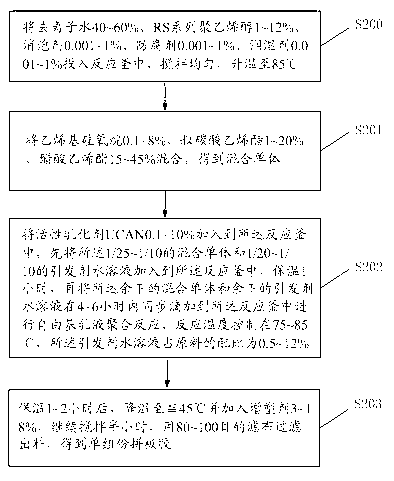

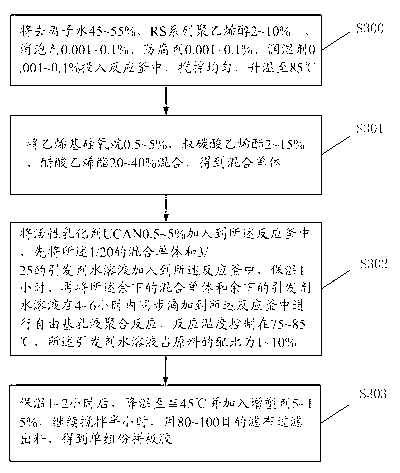

[0080] The invention also provides a preparation method of one-component puzzle glue. Such as figure 1 Shown, described preparation method comprises:

[0081] S100, put 40~60% of deionized water and 1~12% of RS series polyvinyl alcohol into the reaction kettle, stir evenly, and raise the temperature to 85°C.

[0082] The degree of polymerization of the RS series polyvinyl alcohol is 1600-2600.

[0083] Preferably, the degree of polymerization of the RS series polyvinyl alcohol is 1700-2200.

[0084] The RS series polyvinyl alcohol is polyvinyl alcohol RS-1717, polyvinyl alcohol RS-2117 or polyvinyl alcohol RS-4104.

[0085] Preferably, the RS series polyvinyl alcohol is polyvinyl alcohol RS-1717 or polyvinyl alcohol RS-2117.

[0086] The RS series polyvinyl alcohol has strong water resistance.

[0087] S101, mixing 0.1-8% of vinyl siloxane, 1-20% of vinyl tertiary carbonate, and 15-45% of vinyl acetate to obtain a mixed monomer.

Embodiment 1

[0132] Put 53% deionized water, 5% polyvinyl alcohol RS-1717 into the reaction kettle, stir evenly, and raise the temperature to 85°C; mix 1% vinyl siloxane, 5% vinyl tertiary carbonate, and 22% vinyl acetate , to obtain 28% mixed monomer; 2% active emulsifier UCAN is added in the described reactor, first 1 / 20 described mixed monomer and 3 / 25 initiator aqueous solution are joined in the described reactor, keep warm for 1 Hours, then the remaining mixed monomers and the remaining initiator aqueous solution are synchronously added dropwise to the reaction kettle within 4 to 6 hours to carry out free radical emulsion polymerization, the reaction temperature is controlled at 75 to 85 ° C, the The ratio of the initiator aqueous solution to the raw material is 8%; after 1 hour of heat preservation, cool down to ≦45°C and add 4% plasticizer salicylate ether, continue to stir for half an hour, and filter the material with 80~100 mesh filter cloth , to obtain a one-component jigsaw glu...

Embodiment 2

[0134] Put 43% deionized water, 5% polyvinyl alcohol RS-2117 into the reaction kettle, stir evenly, and raise the temperature to 85°C; mix 2% vinyl siloxane, 12% vinyl tertiary carbonate, and 23% vinyl acetate , to obtain 37% mixed monomer; 3% active emulsifier UCAN is added in the described reactor, first 1 / 20 described mixed monomer and 3 / 25 initiator aqueous solution are joined in the described reactor, keep warm for 1 Hours, then the remaining mixed monomers and the remaining initiator aqueous solution are synchronously added dropwise to the reaction kettle within 4 to 6 hours to carry out free radical emulsion polymerization, the reaction temperature is controlled at 75 to 85 ° C, the The ratio of initiator aqueous solution to raw materials is 8%; after 1.5 hours of heat preservation, cool down to ≦45°C and add 4% plasticizer salicylate ether, continue to stir for half an hour, and filter the material with 80~100 mesh filter cloth , to obtain a one-component jigsaw glue. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com