Realization method of programmable controller integrating yarn cleaning and yarn breaking detection

A technology of yarn breakage detection and realization method, applied in the field of control, can solve the problems of complex system redundancy, integrated control of yarn clearing and yarn breakage detection, and cost increase, and achieve the effects of simplified system architecture, high stability, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the programmable (PLC) integrated yarn clearing and thread breaking integrated control method of the present invention, and detailed details are provided below Embodiment and specific operation process, but protection scope of the present invention is not limited to following examples.

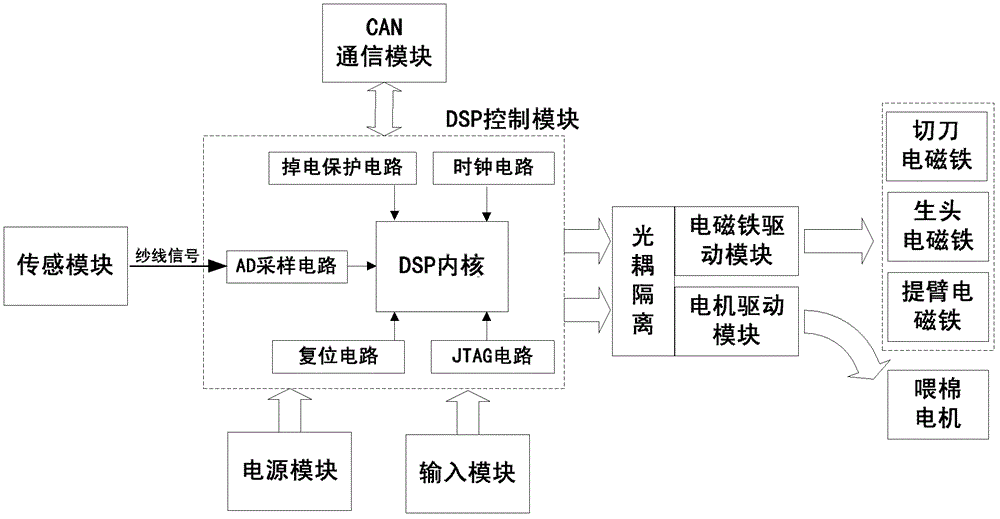

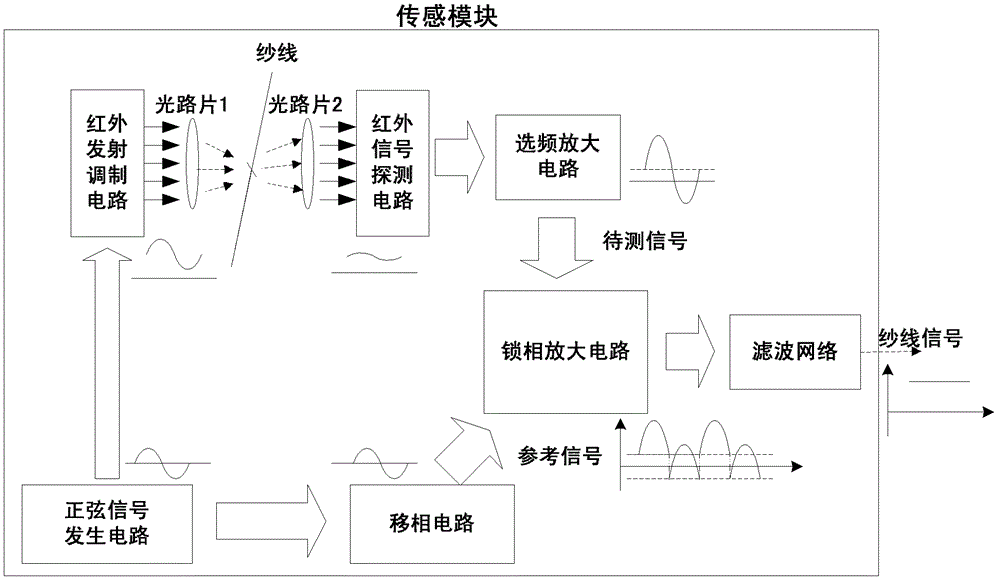

[0035] like figure 1 As shown, this embodiment includes a sensing module, a DSP control module (CPU control module), an input module, a motor drive module, an electromagnet drive module (output module), a CAN communication module, and a power supply module. The DSP control module is respectively connected with the sensor module, the input module, the motor drive module, the electromagnet drive module, the CAN communication module and the power supply module.

[0036] The DSP control module is the core part of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com