Main component device of micro-emission high-energy-saving multiplied tremendous-power pulse knocking engine

A pulse detonation and micro-emission technology, applied to intermittent injection devices, mechanical equipment, etc., can solve the problem of rare commodity discovery, and achieve the effects of low cost, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

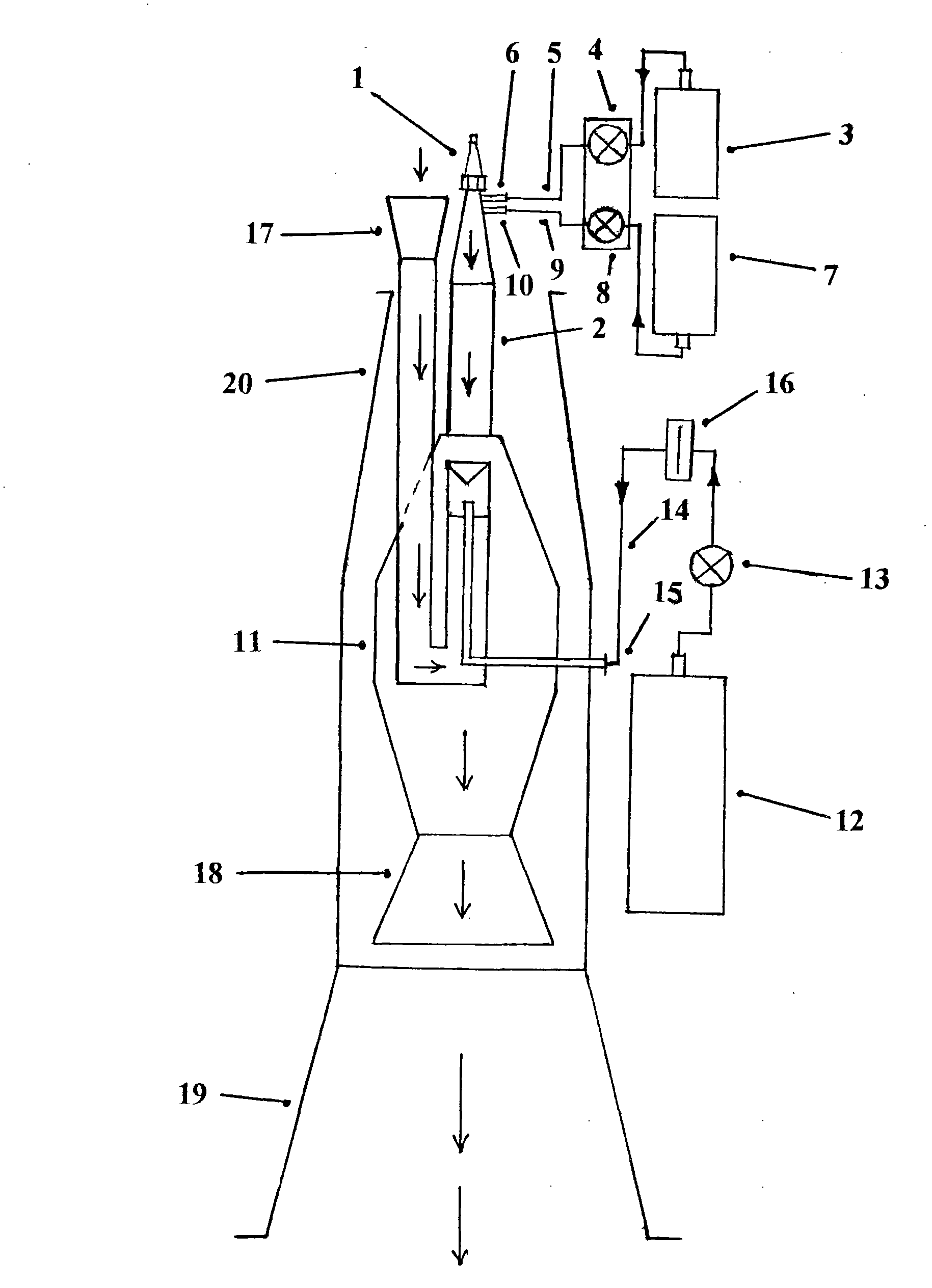

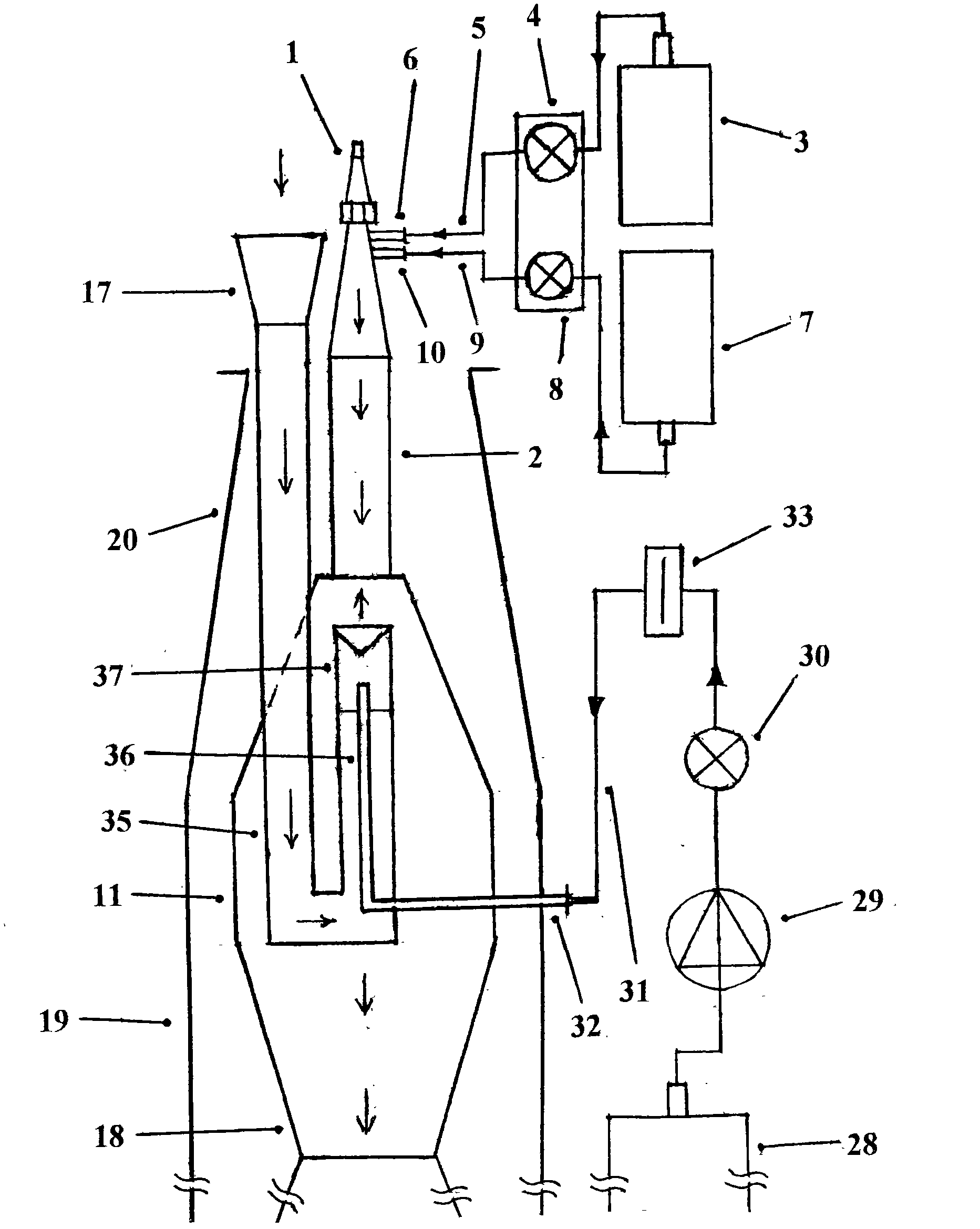

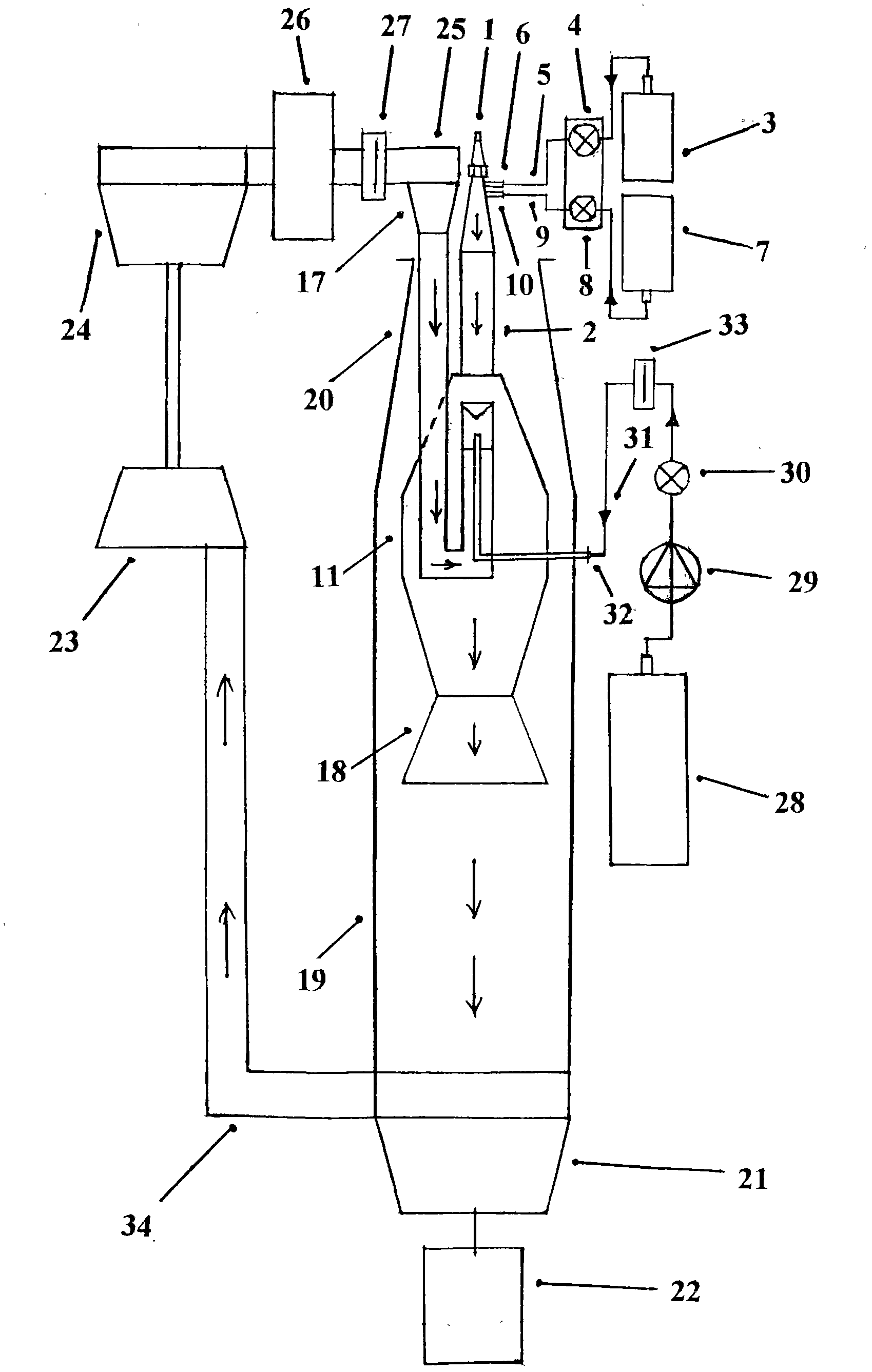

[0012] exist figure 1 Among them, a conical pre-explosion head pulse explosion ignition detonator (2) is arranged at the front of the conical inlet pulse detonation combustion chamber (11), and a high-energy igniter is arranged at the front of the tapered pre-explosion head pulse explosion ignition detonator (2) (1), the front portion of the tapered inlet pulse detonation combustion chamber (11) is provided with a vertical hook-shaped air inlet (17), and the external body of the tapered inlet pulse detonation combustion chamber (11) and the tail nozzle (18) are arranged The secondary air stable combustion outer nozzle pipe (19) is provided for the high temperature wind stable combustion outer nozzle pipe (19), and the secondary wind stable combustion outer cover air intake passage (20) is set at the front part of the high temperature wind stable combustion outer nozzle pipe (19) for the secondary supply. A detonation fuel high-pressure injector (6) and a detonation oxidizer hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com