Van type multifunctional experimental resistance furnace for material thermogravimetric analysis

A thermogravimetric analysis, multi-functional technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problem of low sample consumption and high price (from 40,000 to 50,000 yuan to hundreds of thousands of yuan, and the experimental results are easy to appear) Error and other problems, to achieve the effect of high absolute quality, low equipment investment and small relative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention.

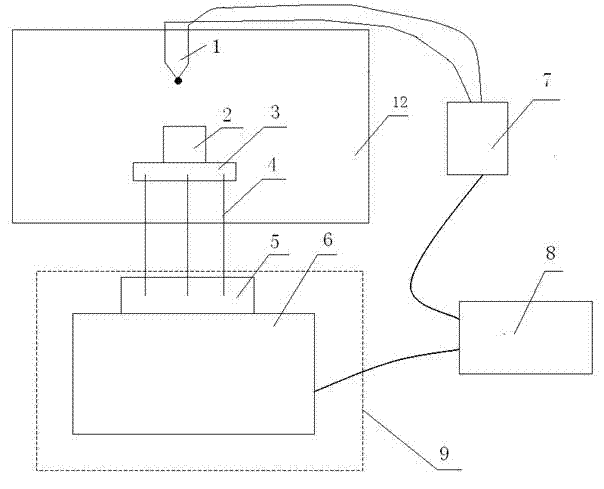

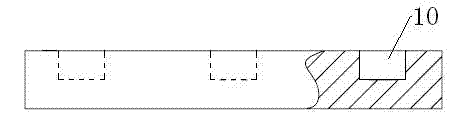

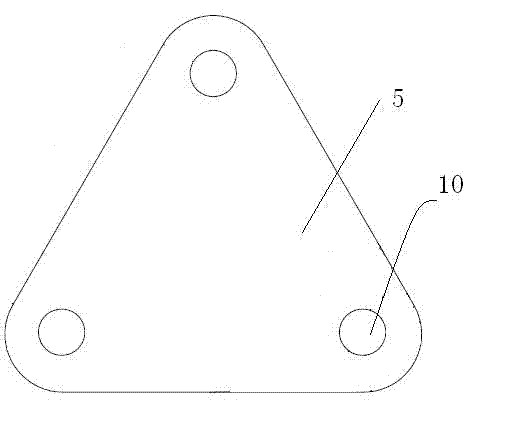

[0028] Reference attached figure 1 , a chamber-type multifunctional experimental resistance furnace for thermogravimetric analysis of materials, comprising a furnace, an electronic analytical balance 6, a temperature controller 7 and a computer 8; the furnace is provided with a temperature measuring thermocouple 1 for sample heating and for A refractory container 2 containing the samples to be analyzed, the refractory container 2 is placed on an upper backing plate 3; the electronic analytical balance 6 is arranged outside the furnace 12, and the electronic analytical balance 6 is provided with a lower backing plate 5, and the lower backing plate 5 passes through the support rod 4 is connected to the backing plate 3, and the computer 8 is connected to the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com