Method for measuring content of titanium dioxide in titanium concentrate

A technology of titanium dioxide and titanium concentrate, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems of easy splashing, corroded corundum crucible, and difficult temperature control. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

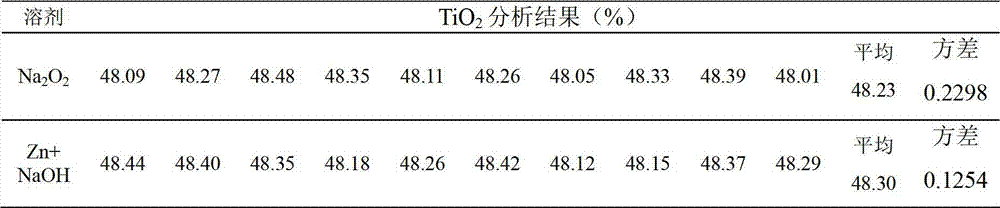

Image

Examples

Embodiment Construction

[0018] The present invention is implemented according to the following technical solutions

[0019] 1) Weighing: first place 1g of zinc powder in a 9ml corundum crucible, weigh 0.3000g (m) of the sample (do a blank test with the sample, the amount of ammonium ferric sulfate standard solution consumed by the blank test is V0) and place it on the zinc powder , Add sodium hydroxide (about 1g) according to 3 times the sample amount, completely cover the sodium hydroxide with 2g of zinc powder, and then evenly cover the surface with 0.1~0.2g of sodium chloride.

[0020] 2) Melting sample: put the crucible in 1) in a muffle furnace at 400°C and heat it up to 820°C for 10 minutes, then take it out and cool it.

[0021] 3) Sample dissolution: Put the sample in 2) together with the crucible into a triangular flask (500ml) filled with 100ml of hydrochloric acid solution (volume ratio to water: 1:1). After the reaction is over, add 40ml of sulfuric acid solution ( The volume ratio of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com