Mg/Zr extreme ultraviolet multilayer film reflector and manufacturing method thereof

A manufacturing method and multilayer film technology, applied to chemical instruments and methods, mirrors, layered products, etc., can solve the problems of poor thermal stability of Mg-based multilayer films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

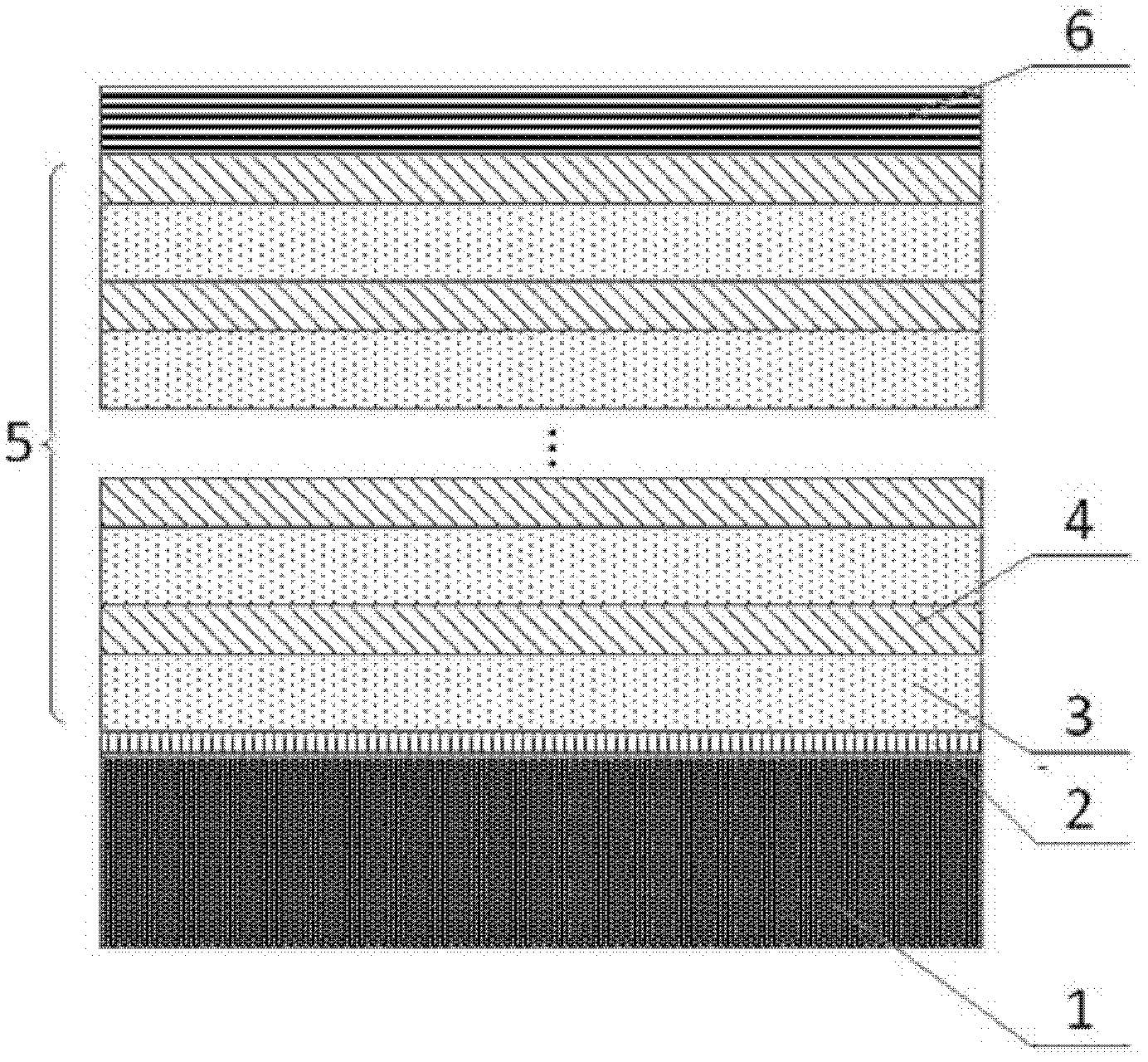

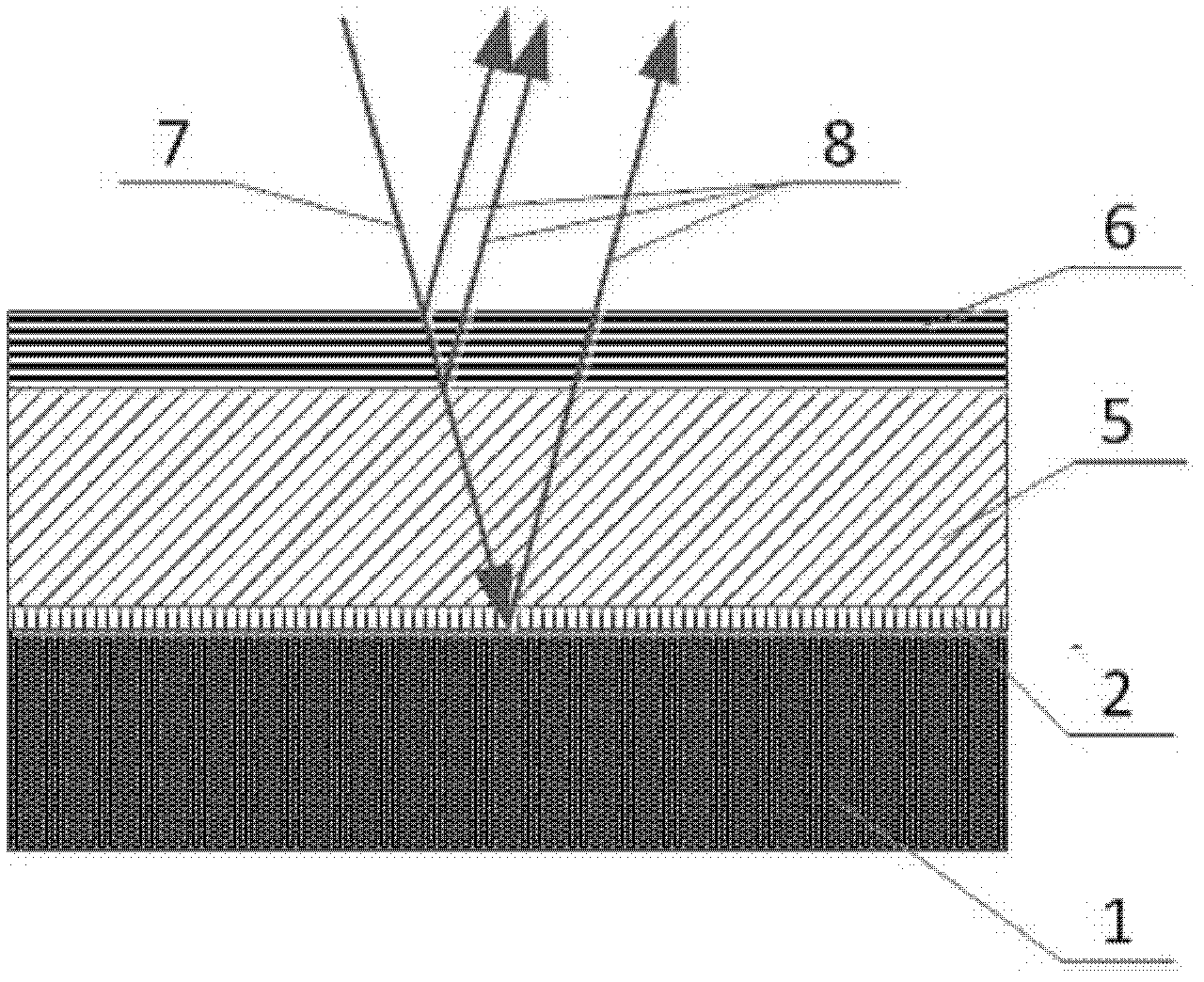

[0024] A Mg / Zr extreme ultraviolet multilayer film reflector, its structure is as figure 1 As shown, the reflector includes a substrate 1, on which a primer layer 2, a Mg / Zr periodic multilayer film 5 and a protective layer 6 are stacked in sequence, wherein the Mg / Zr periodic multilayer film is periodically alternated by Mg films and Zr films Plating composition. The material of the base 1 is a single crystal silicon wafer or glass, and the present embodiment adopts a single crystal silicon wafer whose crystal orientation is (100). -3nm. In this embodiment, it is 2nm. The Mg / Zr periodic multilayer film 5 is plated on the base layer 2, the first layer plated is the Mg film 3, the last layer is the Zr film 4, and the number of cycles is 30-40, the number of cycles in the present embodiment is 40, the total thickness of the Mg / Zr periodic multilayer film 5 is 450-640 nm, and the ratio of the Mg layer thickness to the periodic thickness is 0.6-0.8, which is 0.8 in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com