Control system for doubly-fed induction machine

A technology of doubly-fed induction and control system, applied in the field of doubly-fed machines, can solve the problems of low resonant frequency and no converter, and achieve the effect of easy implementation and high-efficiency damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

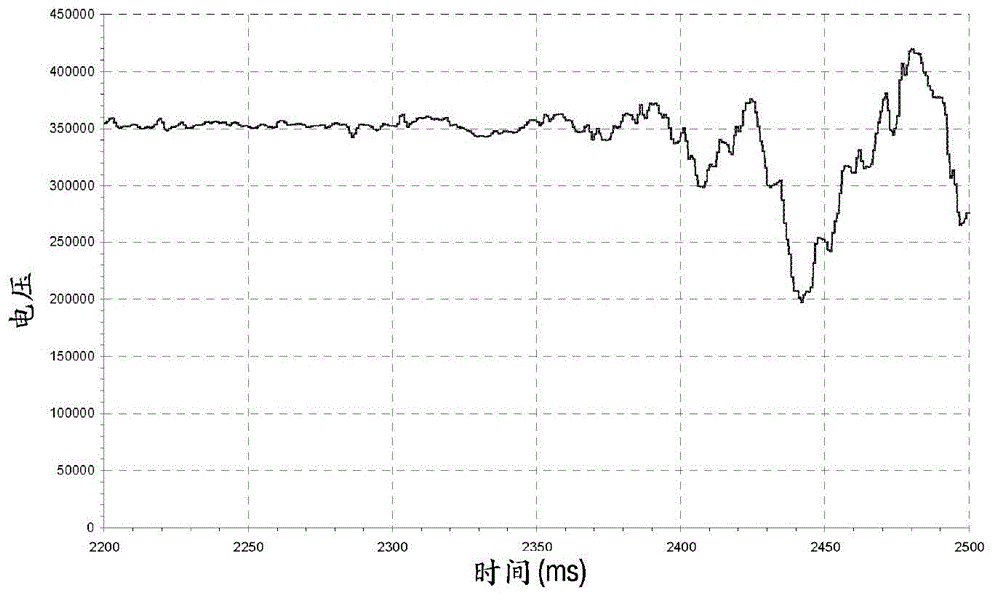

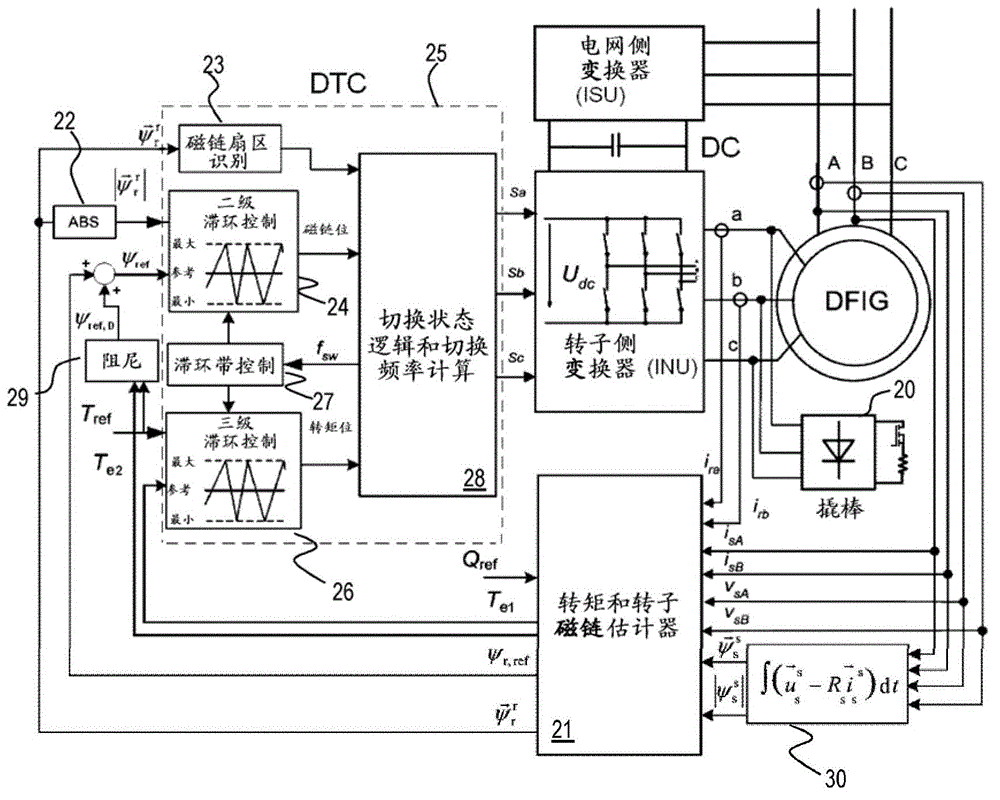

[0019] figure 2 An example of a control system according to an embodiment of the invention together with a frequency converter for controlling a doubly-fed induction generator (DFIG) is shown. figure 2 The control system in is based on direct torque control. It was found that direct torque control tends to excite subsynchronous resonances already at moderately compensated levels of transmission line inductance.

[0020] An example of a conventional prior art direct torque controlled system is disclosed, for example, in US Patent 6,741,059. In a direct torque controlled system, such as that in the aforementioned US patent, machine torque and rotor flux linkage are the controlled variables. The actual values of the torque and the rotor flux vector are estimated from the measured stator current vector, the measured rotor current vector and the stator flux vector. The stator flux vector is estimated by integrating the stator voltage vector.

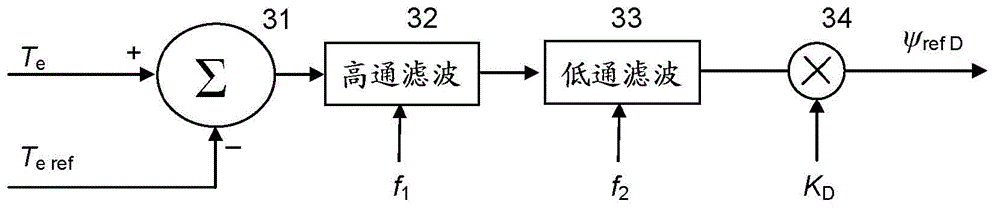

[0021] exist figure 2 In , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com