A kind of concrete and preparation method thereof

A concrete and composite fiber technology, applied in the field of concrete, can solve the problems of reducing the compressive strength and elastic modulus of concrete materials, the mismatch between mechanical properties and deformation properties, and limited damping performance, and achieve excellent damping performance and high-efficiency damping performance , Improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

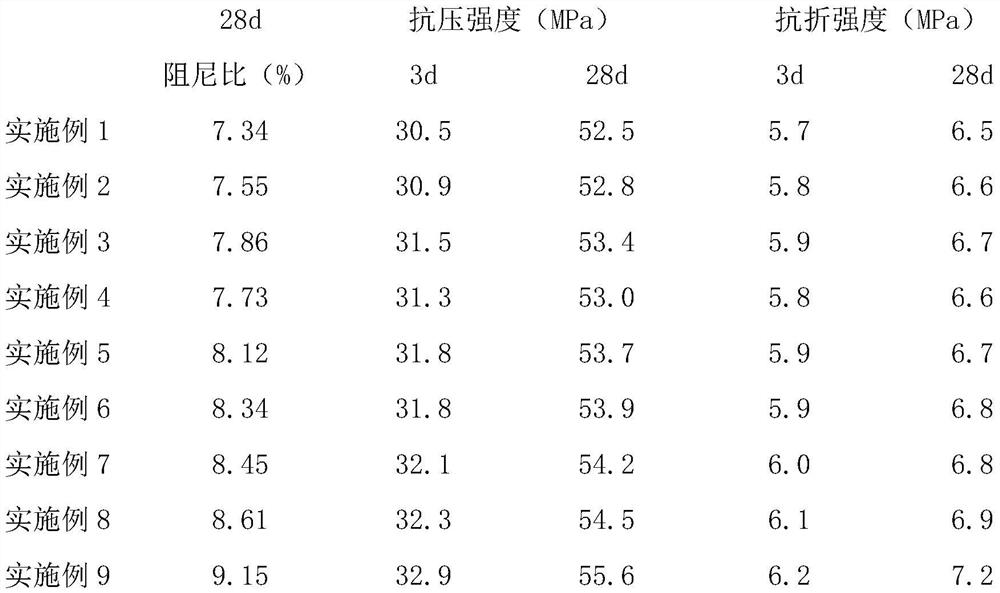

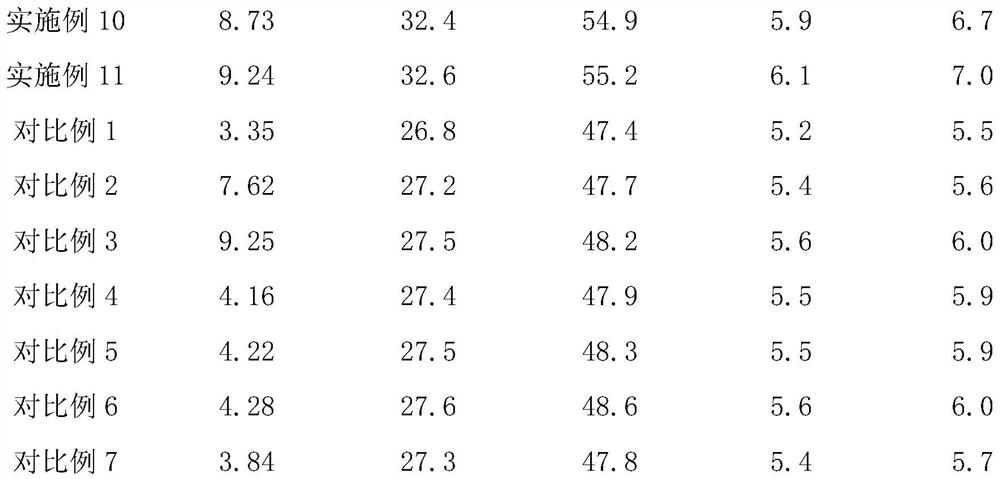

Examples

preparation example 1

[0039] The preparation method of magnesium-based composite fiber is:

[0040] (1) Disperse 1kg of nano-carbon nitride in 2kg of absolute ethanol, ultrasonically vibrate for 30min, and disperse the agglomerated nano-carbon nitride;

[0041] (2) drying and evaporating absolute ethanol to obtain dry nano-carbon nitride, and wrapping with aluminum foil for subsequent use;

[0042] (3) Put 5kg of magnesium alloy into a melting furnace and heat it to 690°C for melting. At the same time, preheat the carbon nitride wrapped in aluminum foil at 200°C. When the magnesium alloy is completely melted, add the preheated nitrogen wrapped in aluminum foil Carbonization, heat preservation at 650°C for 2 hours, introduction of ultrasonic waves into the smelting furnace, the frequency of ultrasonic waves is 20KHz, ultrasonic waves for 15min, the molten liquid is poured into the mold to cast ingots, and magnesium-based composite ingots are obtained;

[0043] (4) Milling the magnesium-based compos...

preparation example 2

[0045] (1) Disperse 1kg nano-carbon nitride in 2kg absolute ethanol, ultrasonically vibrate for 45min, disperse and agglomerate nano-carbon nitride;

[0046] (2) drying and evaporating absolute ethanol to obtain dry nano-carbon nitride, and wrapping with aluminum foil for subsequent use;

[0047] (3) Put 5kg of magnesium alloy into a melting furnace and heat it to 690°C for smelting. When the magnesium alloy is completely melted, add carbon nitride wrapped in aluminum foil, keep it at 650°C for 2 hours, and introduce ultrasonic waves into the melting furnace. The frequency of the ultrasonic wave is 20KHz, ultrasonic for 15min, pour the molten liquid into the mold and cast the ingot to obtain the magnesium-based composite ingot;

[0048] (4) Milling the magnesium-based composite ingot to obtain the magnesium-based composite fiber, the cross-section of the magnesium-based composite fiber is circular, the length is 40 mm, and the diameter is 0.5 mm.

preparation example 3

[0050] (1) Disperse 1kg nano-carbon nitride in 2kg absolute ethanol, ultrasonically vibrate for 45min, disperse and agglomerate nano-carbon nitride;

[0051] (2) drying and evaporating absolute ethanol to obtain dry nano-carbon nitride, and wrapping with aluminum foil for subsequent use;

[0052] (3) Put 5kg of magnesium alloy into the melting furnace and heat it to 700°C for melting. At the same time, preheat the carbon nitride wrapped in aluminum foil at 250°C. When the magnesium alloy is completely melted, add the preheated nitrogen wrapped in aluminum foil Carbonization, heat preservation at 650°C for 2 hours, introduction of ultrasonic waves into the smelting furnace, the frequency of ultrasonic waves is 20KHz, and ultrasonic waves for 20min, the molten liquid is poured into the mold to cast ingots to obtain magnesium-based composite ingots;

[0053] (4) Milling the magnesium-based composite ingot to obtain the magnesium-based composite fiber, the cross-section of the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com