Ultrathin bean flour and bean nutrition meal bars

A technology for meal replacement bars and bean flour, applied in baking, baked goods, food preparation and other directions, can solve problems such as non-utilization, and achieve the effects of suitable taste, attractive color and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

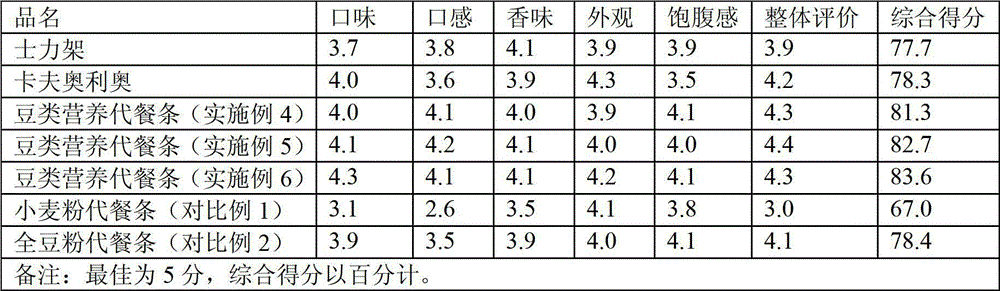

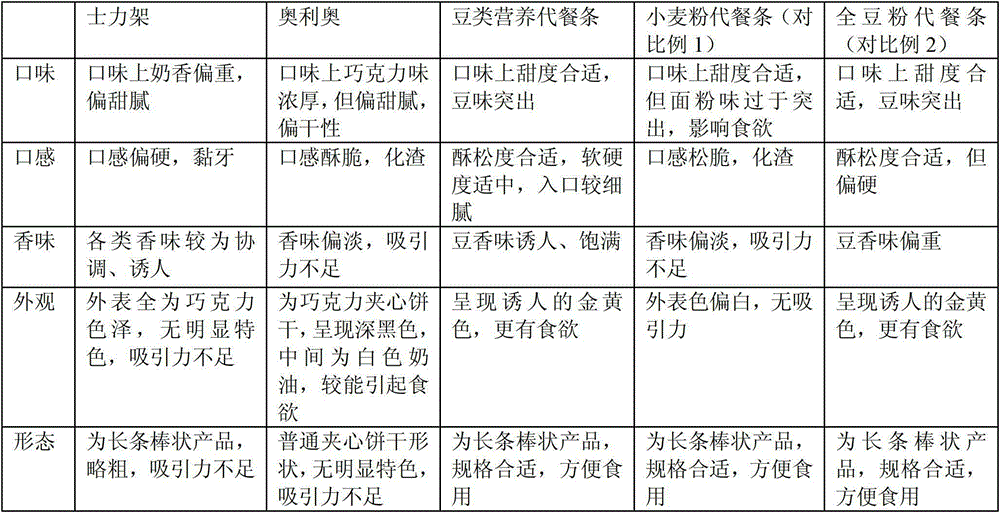

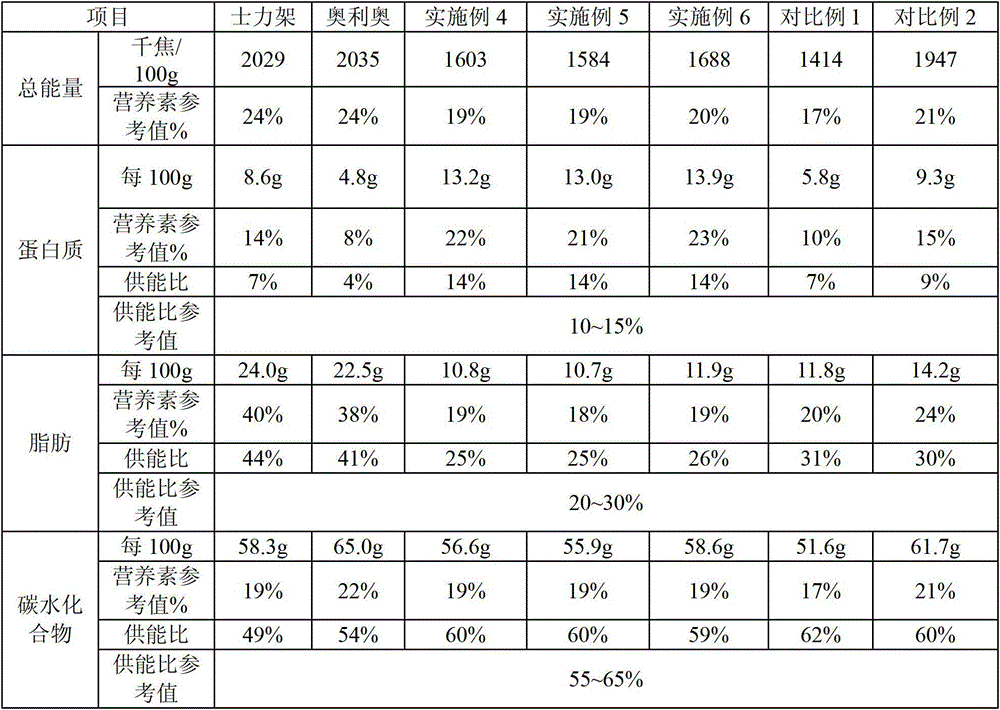

Examples

preparation example Construction

[0108] The preparation method of the bean nutrition meal replacement bar of the present invention comprises the following steps:

[0109] a. Raw material pretreatment: 15~45 parts of eggs are shelled, stirred evenly into egg liquid; the powder is mixed evenly; wherein, the powder includes 10~50 parts of soybean powder, 10~50 parts of ultrafine soybean powder, 20~60 parts of Starch, 1~15 parts milk powder, 0.3~1.5 parts salt;

[0110] b. Mixing: Mix 10~50 parts of butter and egg liquid for 1~5 minutes, then add the powder mixed evenly in step a, and stir evenly for 1~5 minutes to form a dry billet;

[0111] c. Forming: put the dry billet into the extruder for extrusion molding, and the forming specification is 2~5cm×2~5cm×6~15cm;

[0112] d. Baking: bake the formed dry billets at a temperature of 180~220°C for 18~22 minutes;

[0113] e. Cooling: Cool the baked dry billet to 4~7°C, pack it, and get the finished product.

[0114] Further, the powder in step a also includes 0.5...

Embodiment 1

[0139] Embodiment 1 prepares superfine bean flour

[0140] The soybean meal powder was put into a jet mill (the speed of the mill was set at 40 Hz) for fine grinding for 20 minutes to obtain superfine soybean flour. Measured by the Bettersize2000B intelligent laser particle size analyzer, the D 90 =6.5μm.

Embodiment 2

[0141] Embodiment 2 prepares superfine bean flour

[0142] Soybean meal powder was put into a jet mill (the speed of the mill was set at 45 Hz) for fine grinding for 30 minutes to obtain superfine soybean flour. Measured by the Bettersize2000B intelligent laser particle size analyzer, the D 90 = 10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com