A Gas-Solid Distributor for Reducing Backmixing at the Riser Outlet of a Combined Fluidized Bed in Series

A technology of series combination and riser, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the riser, and achieve the effects of reducing back-mixing, easy transformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

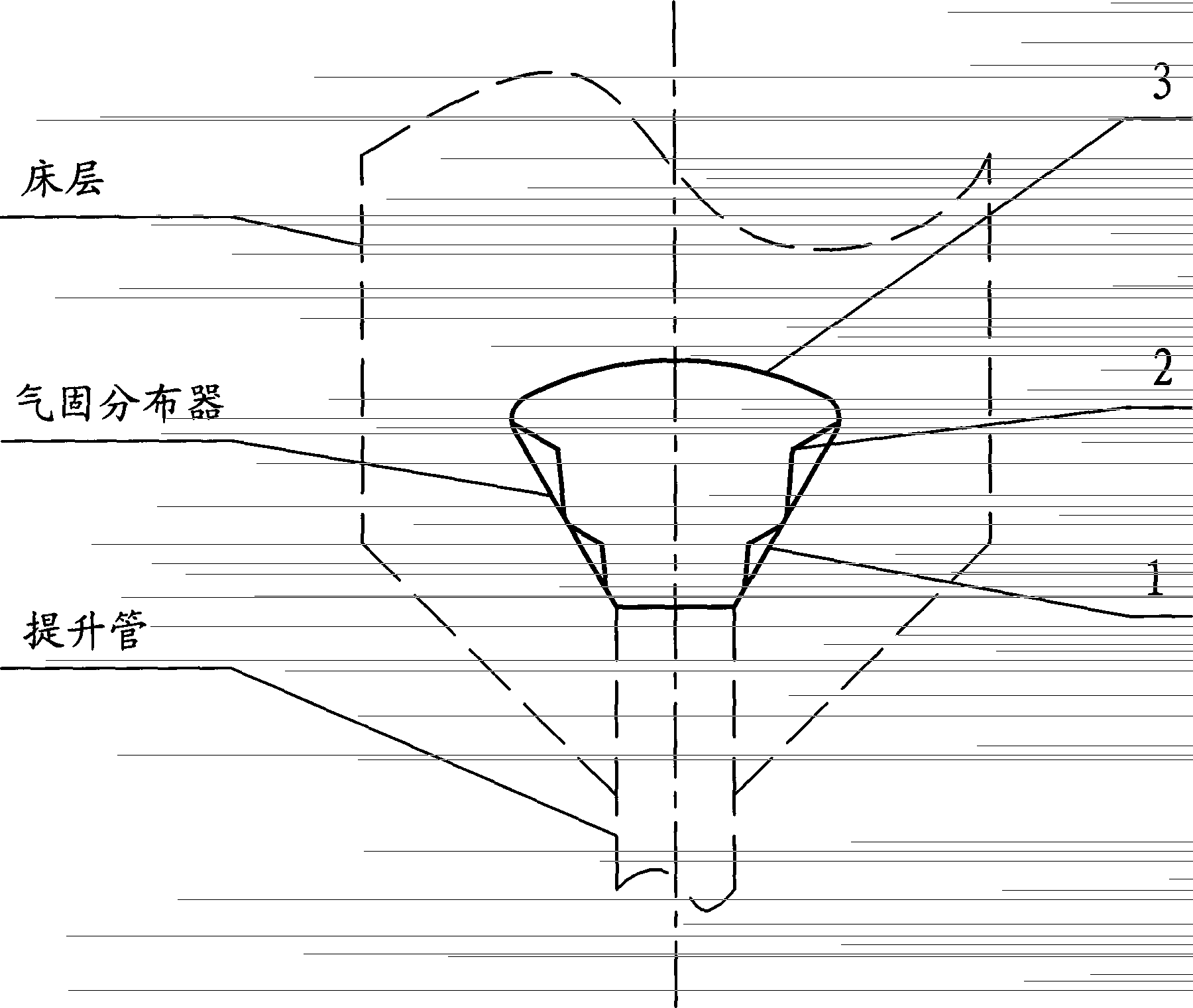

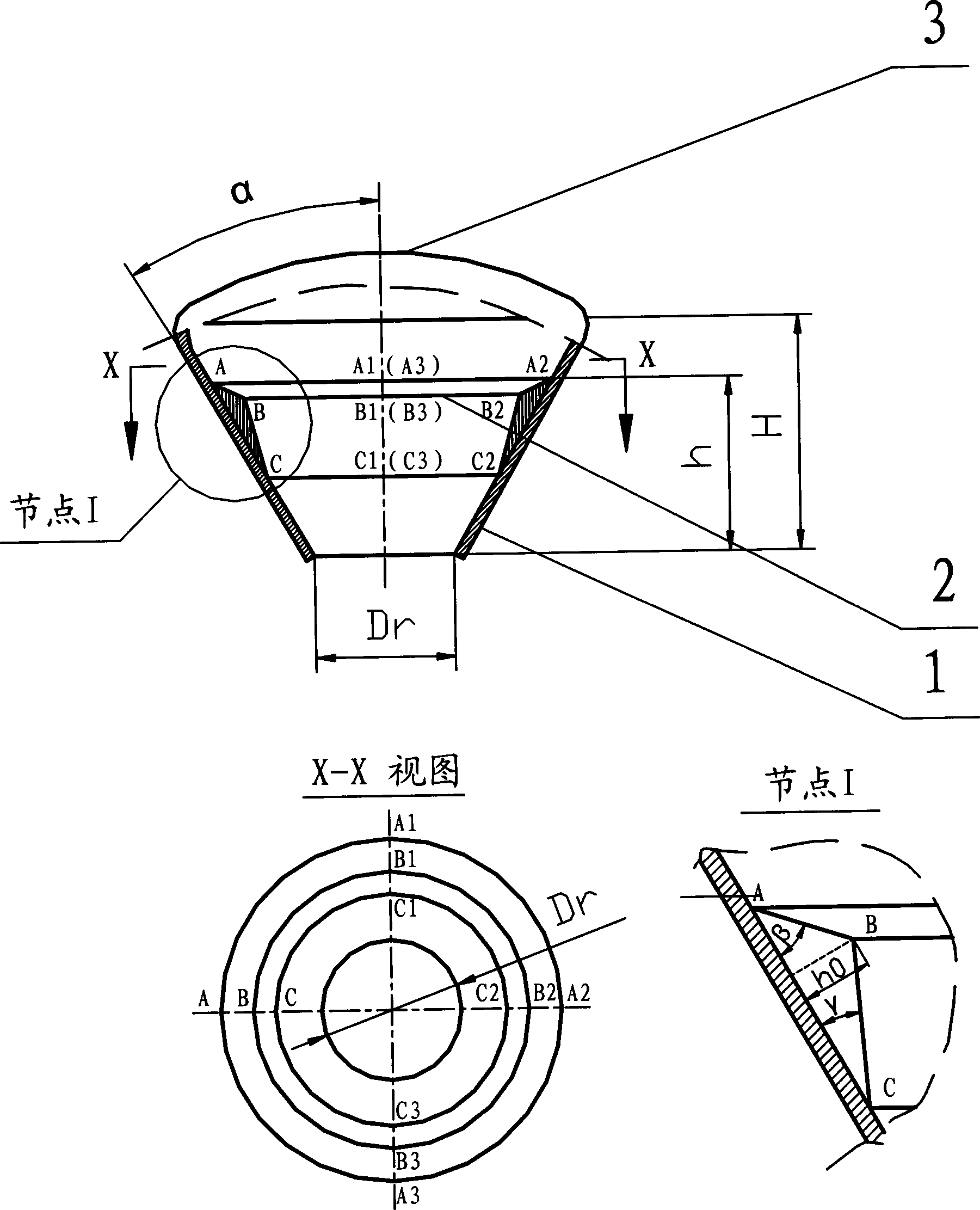

[0028] See attached figure 1 And attached figure 2 , a gas-solid distributor for reducing backmixing at the riser outlet of a series combined fluidized bed in this embodiment, comprising: a hollow inverted cone 1 , a cone 2 , and a distribution plate 3 . The cone edge 2 is closely connected to the inner surface of the hollow inverted cone 1, the distribution plate 3 is provided with gas and particle outflow holes, the distribution plate 3 is closed and connected with the upper end surface of the hollow inverted cone 1, and the hollow inverted cone 1 The end surface is closed and connected with the outlet of the riser, and the hollow inverted cone 1 connected with the distribution plate 3 extends into the bed.

[0029] The hollow inverted conical frustum 1 is a conical frustum, the upper end surface and the lower end surface are open openings, the equivalent diameter Dr of the lower end surface is equal to the equivalent diameter of the riser connected to it, the height H=(0....

Embodiment 2

[0035] See attached figure 1 And attached figure 2 , a gas-solid distributor for reducing backmixing at the riser outlet of a series combined fluidized bed in this embodiment, comprising: a hollow inverted cone 1 , a cone 2 , and a distribution plate 3 . The connection mode of the hollow inverted cone 1, the cone 2, and the distribution plate 3 is the same as that of embodiment 1, the structure of the hollow inverted cone 1 and the cone 2 is the same as that of embodiment 1, and the structure of the distribution plate 3 is the same as that of embodiment 1 different.

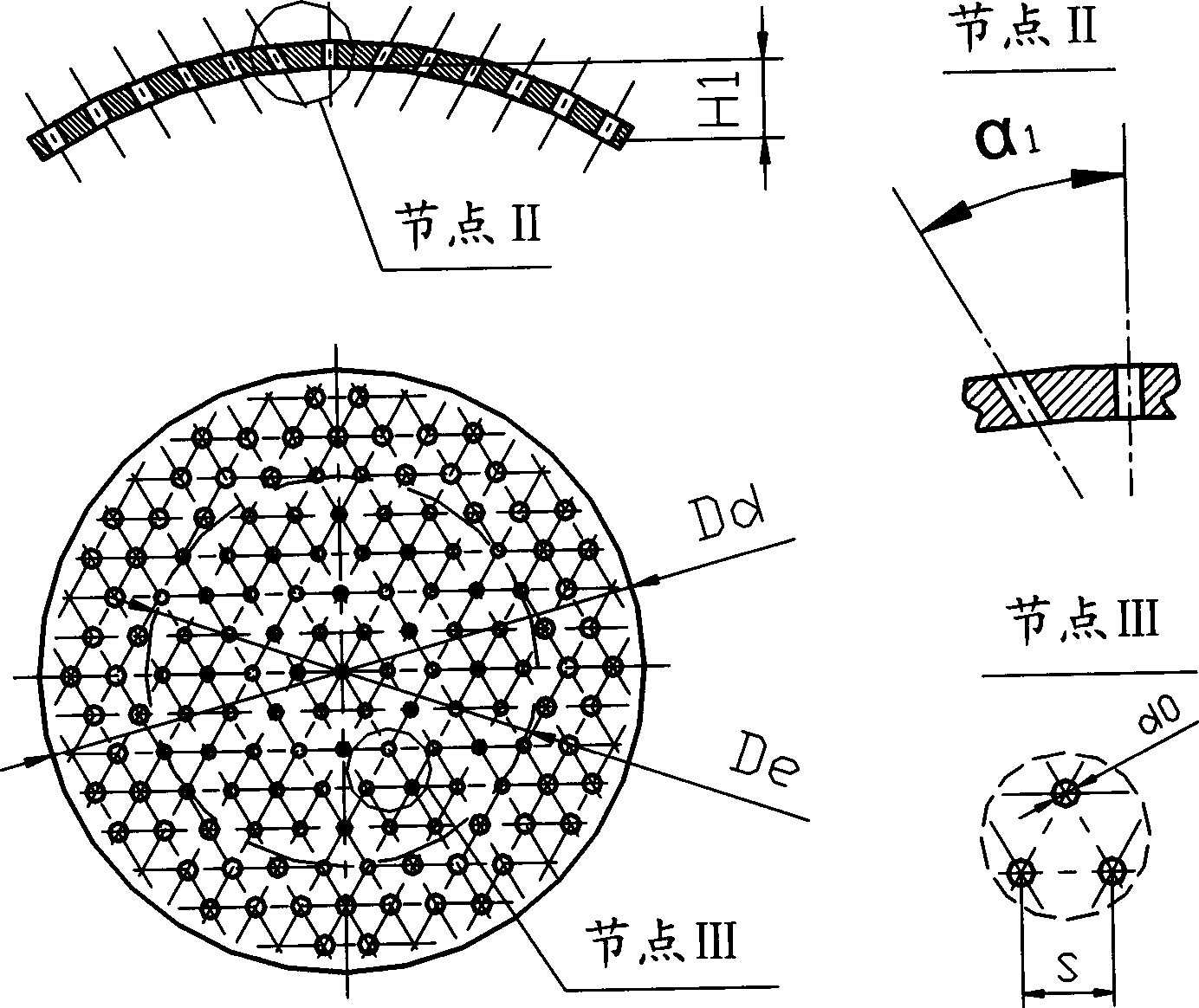

[0036] See attached Figure 4 , the distribution plate 3 is a concave arc panel, and the inner arc surface height H1=(0.2~0.4)Dr of the concave arc panel; the opening ratio K1 based on the section of the riser in the area of the horizontal projection diameter De<0.5Dd of the distribution plate 3 = 20% to 30%, in the area of distribution plate 3 horizontal projected diameter De=0.5Dd~Dd, the opening rate K...

Embodiment 3

[0040] See attached figure 1 And attached Figure 5 , a gas-solid distributor for reducing backmixing at the riser outlet of a series combined fluidized bed in this embodiment, comprising: a hollow inverted cone 1 , a cone 1 , and a distribution plate 3 . The cone edge 2 is closely connected to the inner surface of the hollow inverted cone 1, the distribution plate 3 is provided with gas and particle outflow holes, the distribution plate 3 is closed and connected with the upper end surface of the hollow inverted cone 1, and the hollow inverted cone 1 The end surface is closed and connected with the outlet of the riser, and the hollow inverted cone 1 connected with the distribution plate 3 extends into the bed.

[0041] The hollow inverted conical frustum 1 is a conical frustum, the upper end surface and the lower end surface are open openings, the equivalent diameter Dr of the lower end surface is equal to the equivalent diameter of the riser connected to it, the height H=(0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com