Hammer head for two-fluid duplex metal composite hammer crusher and manufacturing method thereof

A hammer crusher, double-fluid bimetal technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of high cost and low bonding strength, and achieve long service life, reliable crack resistance, The effect of strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

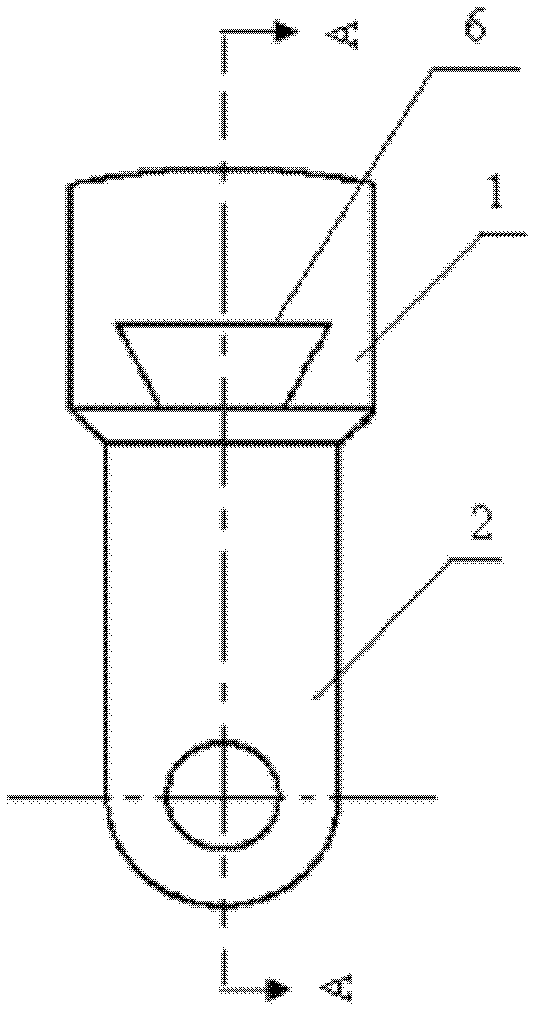

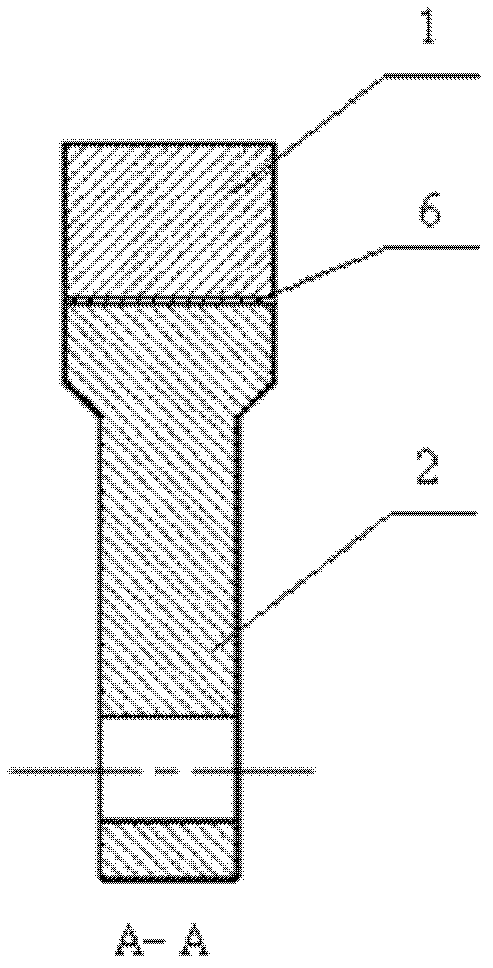

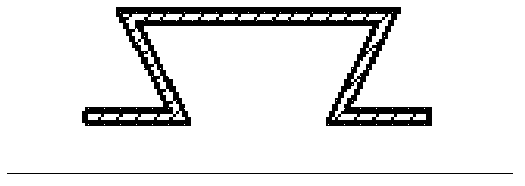

[0012] Embodiment 1: A hammer head for a double-fluid bimetal compound hammer crusher in this embodiment is composed of a head 1 , a hammer handle 2 and a dovetail partition 6 between the head and the hammer handle.

[0013] The hammer head of the double-liquid bimetallic compound hammer crusher in this embodiment uses two pouring systems, and the two metal liquids are poured at the same time. The timing is not accurate and the molten metal is mixed with each other, and a dovetail-shaped partition is inserted at the part where the head and the hammer handle are combined in the cavity. The temperature of the molten metal during pouring can not only partially melt the dovetail-shaped separator under the action of the molten metal, but also have a complete bonding interface, and can also play a corresponding isolation role to obtain metallurgical bonding, which will not fall off during use and prolong the use. Longer life, lower overall production cost.

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that the material of the head 1 is high chromium cast iron, low chromium anti-wear white cast iron, medium chromium anti-wear white cast iron or high manganese steel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the hammer handle 2 is made of cast steel or low-alloy steel. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com