Method for processing orientation-deflected seed crystals

A processing method and crystal orientation technology, which is applied in the field of monocrystalline silicon single crystal seed crystal production, can solve problems such as inapplicability and difficulty in achieving precise control, so as to increase output, improve alignment accuracy, and reduce deviation distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

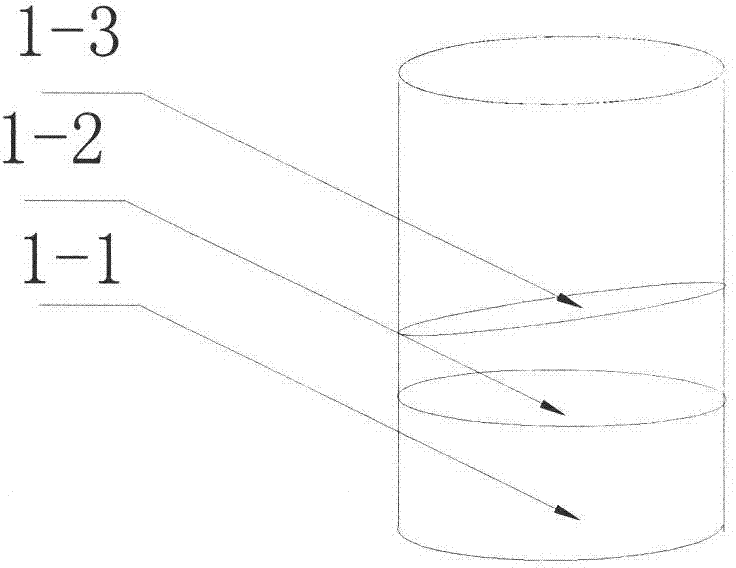

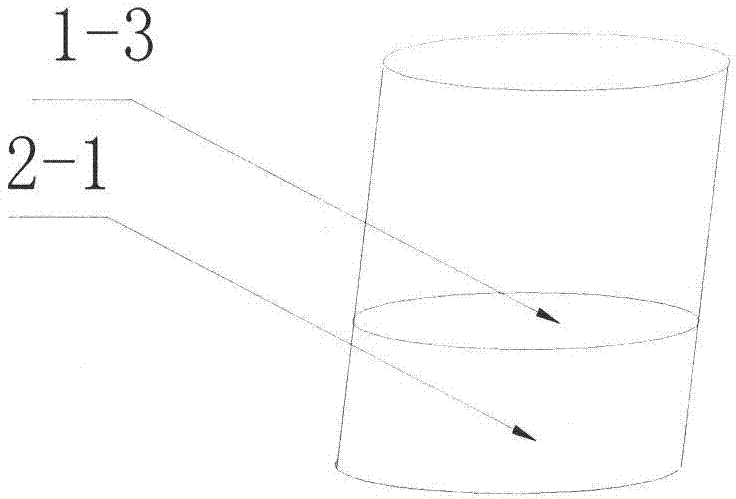

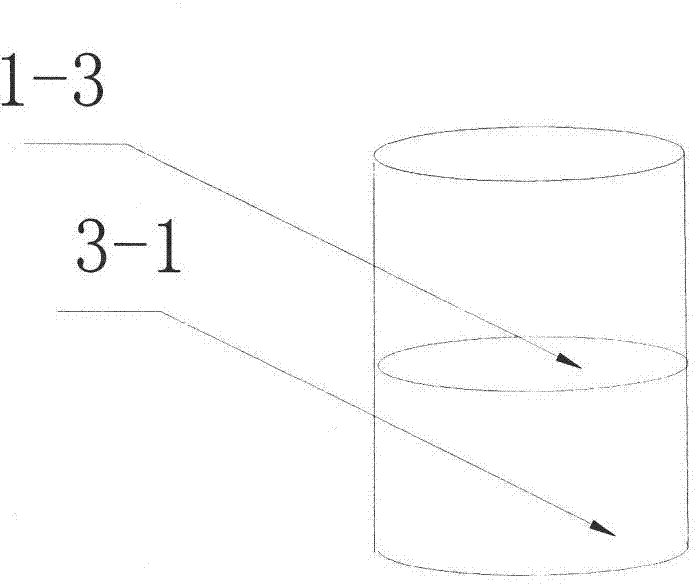

Image

Examples

Embodiment 1

[0046] N-type silicon single crystal 4-inch silicon wafers with a partial crystal orientation of 4° are used for the production and processing of orthocrystalline seed crystals and partial crystal orientation seed crystals of 3° respectively.

[0047] 1. Single crystal growth: use 2 sets of CG-3000 single crystal furnaces, 14-inch thermal field growth, grow 4-inch silicon single crystals respectively, and feed 25kg.

[0048] 2. Carry out single crystal growth according to the process of charging, heating, chemical material, seeding, seeding, shouldering, shoulder turning, equal diameter and finishing process, and obtain one orthocrystalline ingot and one crystal ingot with monomorphic orientation.

[0049] 3. Carry out single crystal cutting according to the requirements of resistivity, cut 300mm long crystal ingots from each crystal ingot, and carry out wire cutting and glue according to the partial crystal direction of 4°, and use the same multi-wire cutting machine to cut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com