A light-emitting diode chip and its manufacturing method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of many times of photolithography, achieve the effect of simplifying the process steps, increasing the area of the light-emitting area, and saving the number of times of photolithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

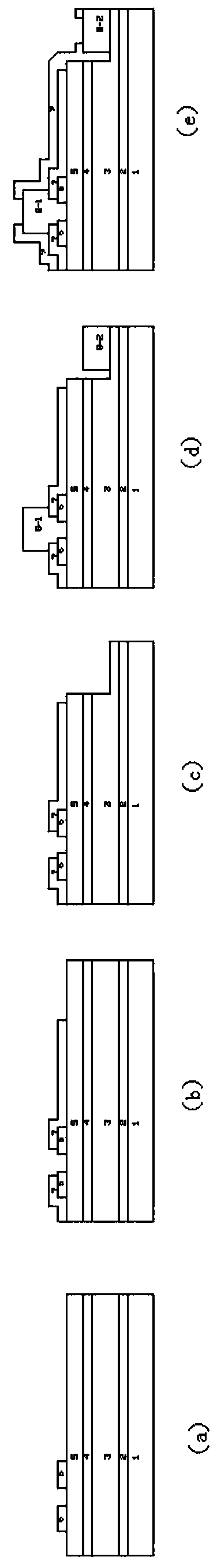

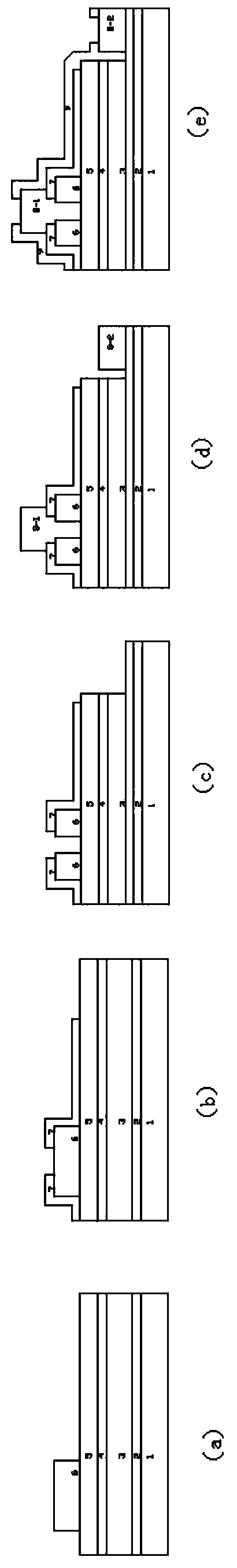

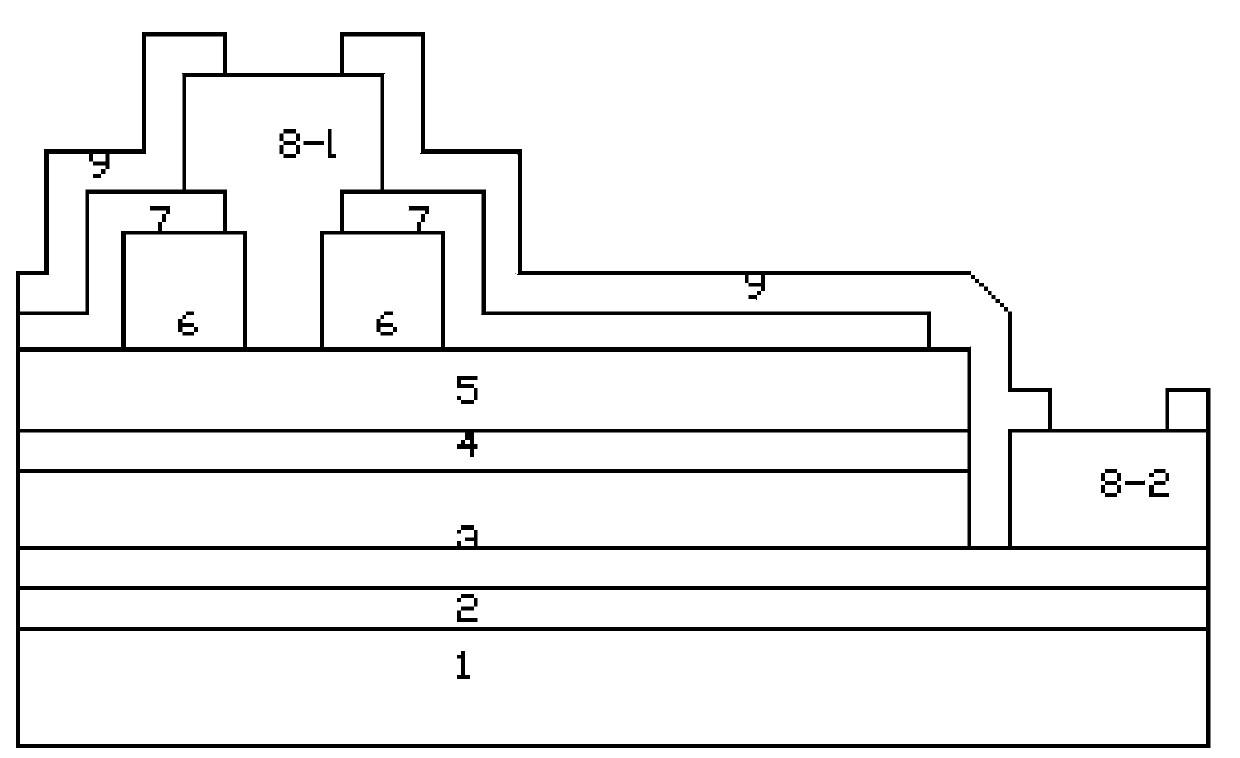

[0027] see figure 1 , figure 2 , the application provides a simpler manufacturing method, which specifically includes the following steps:

[0028] Step 1: disposing the buffer layer on the substrate along the axial direction, disposing the N-type semiconductor layer on the buffer layer; disposing the light-emitting layer on the N-type semiconductor layer, disposing the P-type semiconductor layer on the light-emitting layer;

[0029] Step 2: Deposit the current blocking layer on the upper part of the chip body by plasma enhanced chemical vapor deposition, and make the required pattern by photolithography. At this time, the current blocking layer under the P electrode is not open. see figure 2 (a) and figure 2 (b).

[0030] Step 3: The transparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com