Cluster control system of light and energy-saving wall plate forming production line

A wallboard forming and cluster control technology, applied in the field of cluster control, can solve the problems of high labor intensity, low efficiency, and difficulty in guaranteeing the forming quality of workers, so as to reduce the labor intensity of workers, reduce production costs, and reduce uncontrollable factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

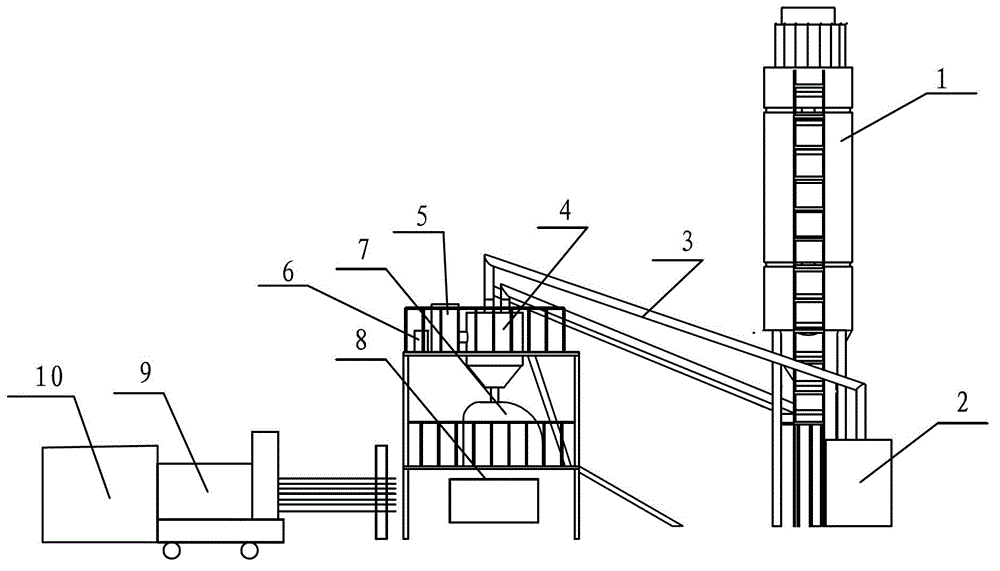

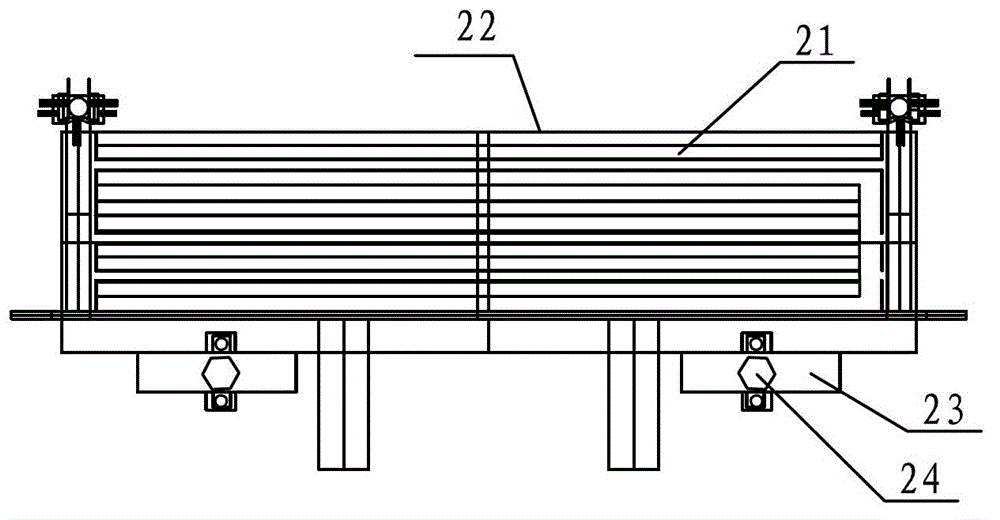

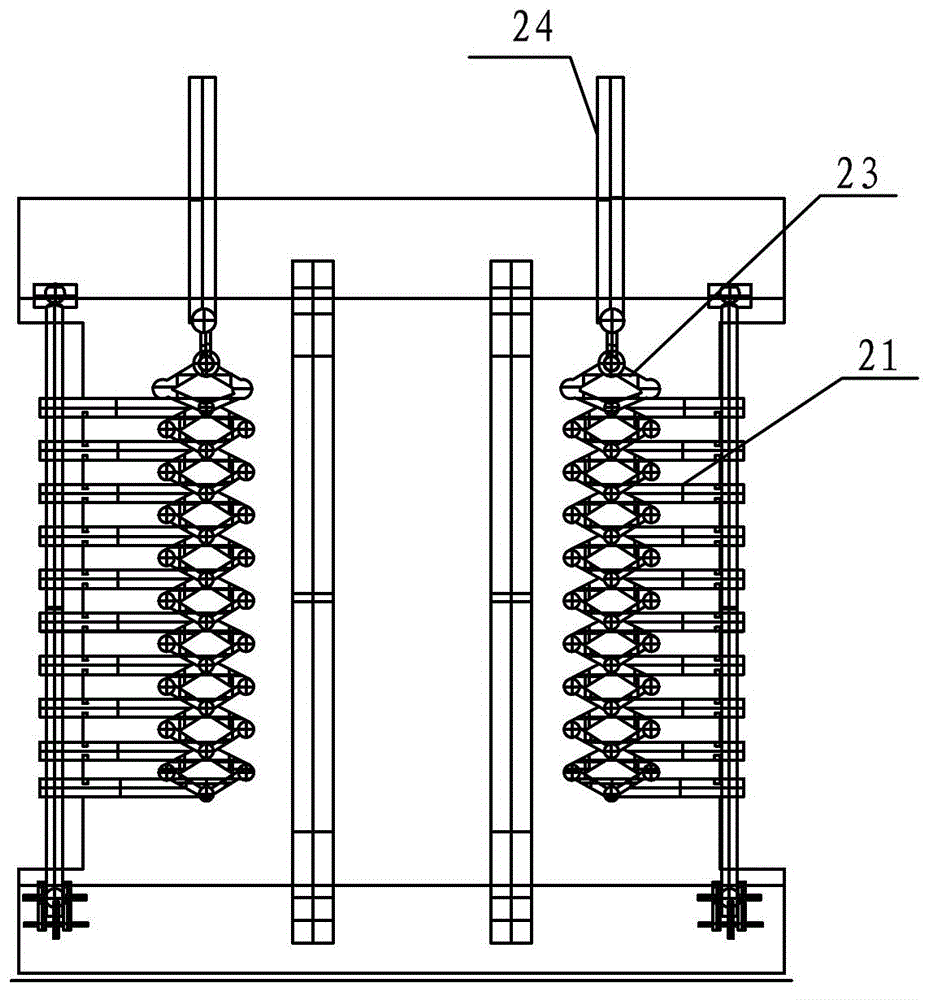

[0025] Such as Figure 1 to Figure 5 As shown, a cluster control system of a light-weight and energy-saving wallboard forming production line of the present invention is used to realize automatic control of the light-weight and energy-saving wallboard forming production line.

[0026] Such as figure 1 As shown, the wallboard molding production line according to the present invention includes a storage tank 1, an EPS curing silo 2, a screw conveyor 3, an electronic metering storage silo 4, a water tank 5, and a foaming device 6 arranged in sequence according to the material conveying direction , Foaming mixer 7, wall panel forming machine 8, pipe-through device 9 and overall board-out device 10. The working process of the wallboard molding production line is as follows: the raw materials in the storage tank 1 and the EPS curing silo 2 are transported to the electronic metering storage silo 4 through the screw conveyor 3, and after being measured, they will enter the foaming to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com